Chapter 3 Fuel Injection Equipment

1. Fuel Supply System

4LHA Series

E

å

tr.

s

-j

RE

G

(Continuous

rated

output)

Cam

speed

Engine

speed

-

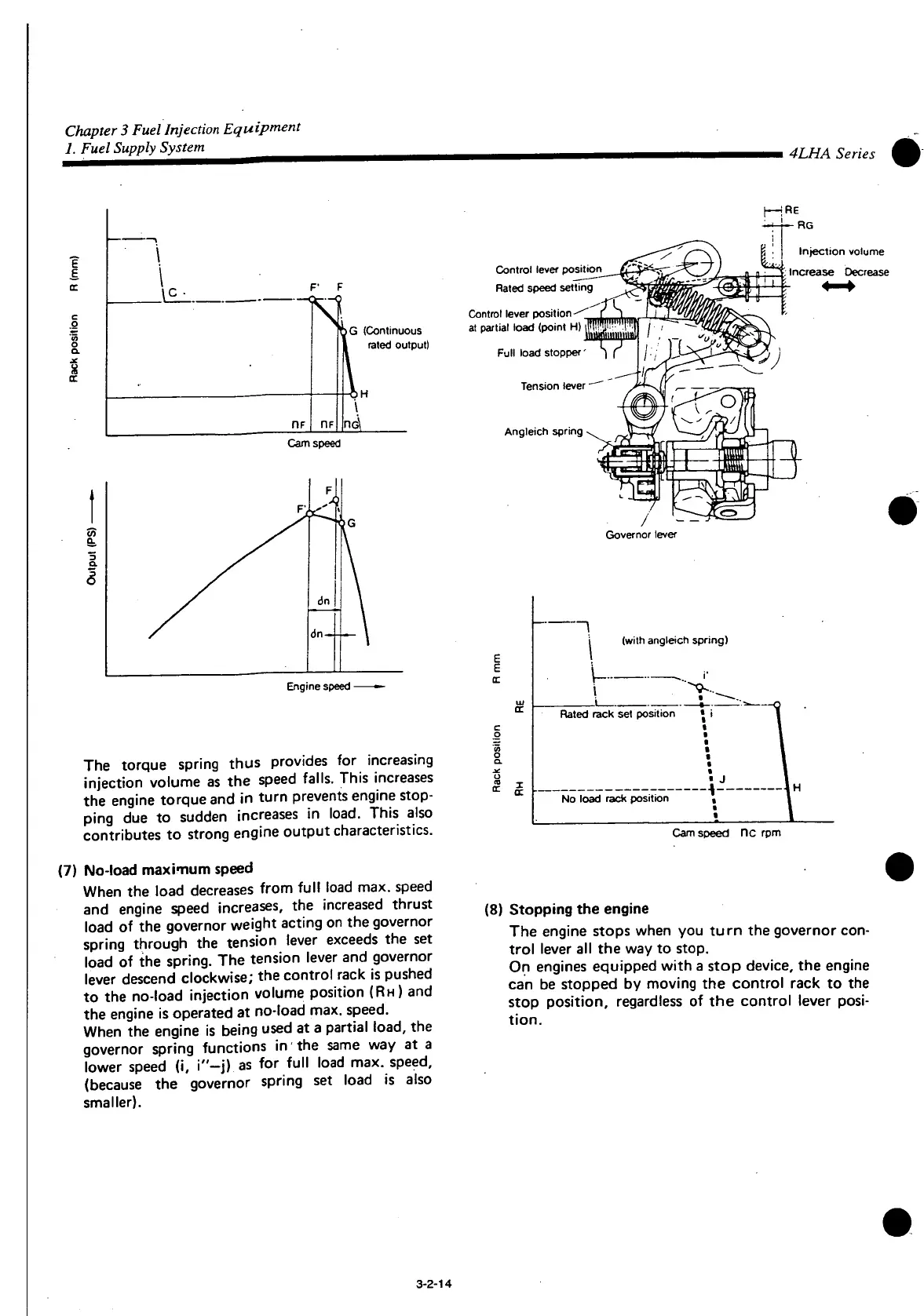

The torque spring thus provides for increasing

injection volume as the speed falls. This increases

the engine torque and in

turn

prevents engine stop-

ping due to sudden increases in load. This also

contributes to strong engine

output

characteristics.

(7)

No-load

maximum

speed

When the load decreases

from

full

load max. speed

and engine speed increases, the increased

thrust

load of the governor weight acting on the governor

spring through the tension lever exceeds the set

load of the spring. The tension lever and governor

lever descend clockwise; the control rack is pushed

to the no-load injection volume position

(RH

) and

the engine is operated at no-load max.

speed.

When the engine is being used at a partial load, the

governor spring functions in the same way at a

lower speed (i, i"-j) as for

full

load max.

speed,

(because

the governor spring set load is also

smaller).

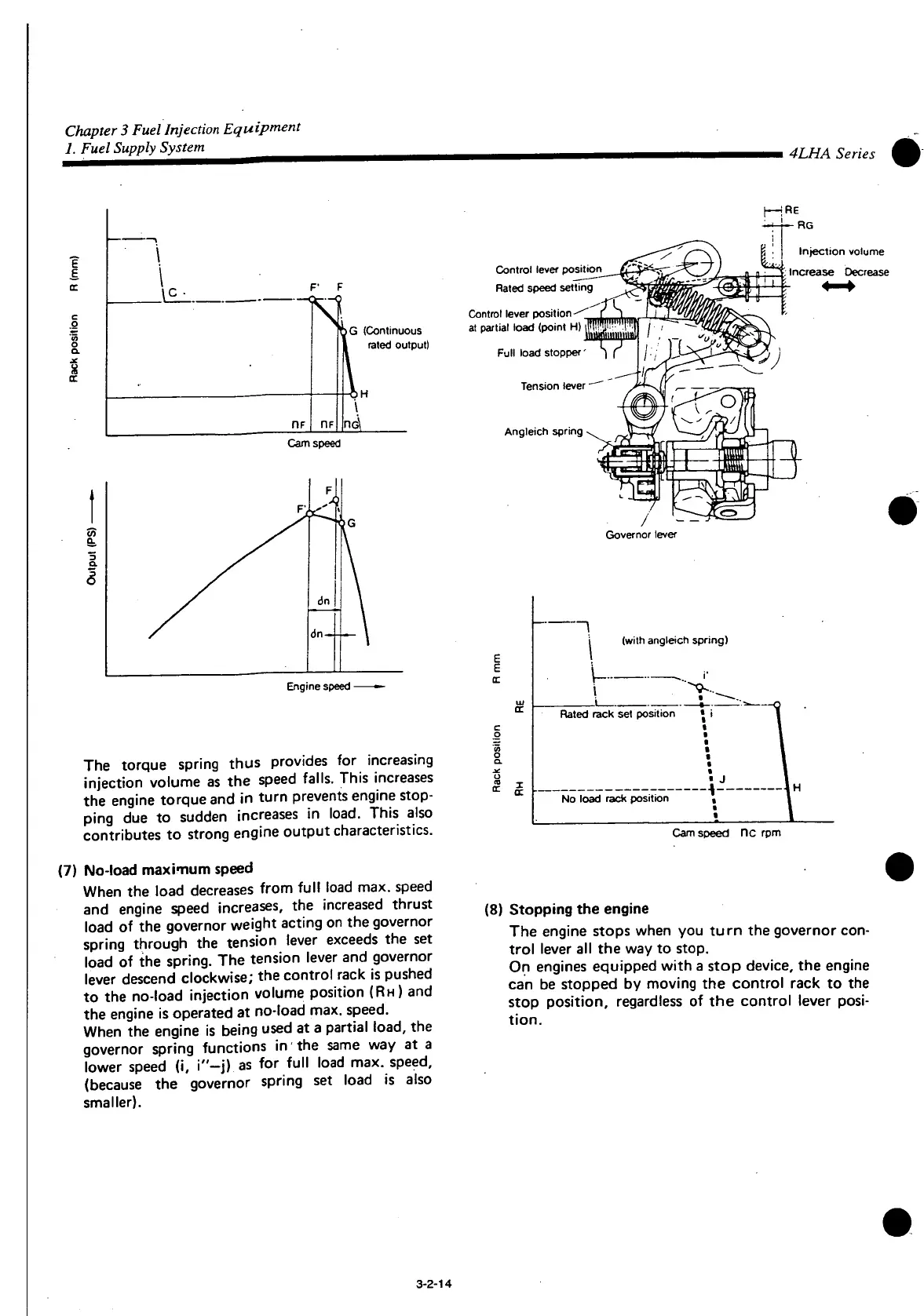

Control lever position

Rated

speed setting

Control lever position--

-

at partial load

(point

H)

Full

load stopper' ^ f

Tension

lever

Angleich

spring

-RG

I '.

Injection

volume

Increase Decrease

/

Governor

lever

E

E

cc

3

"1

(with

angleich spring)

Rated

rack set position » i

No

load rack position

Cam

speed nc rpm

(8)

Stopping

the

engine

The engine stops when you

turn

the governor

con-

trol

lever all the way to stop.

On

engines equipped

with

a stop device, the engine

can

be stopped by moving the control rack to the

stop position, regardless of the control lever

posi-

tion.

3-2-14

Loading...

Loading...