Chapter 7 Reduction and Reversing Gear

3. Inspection and Servicing

3-5-1

Lapping

Procedure

for

Drive

Cone

4LHA Series

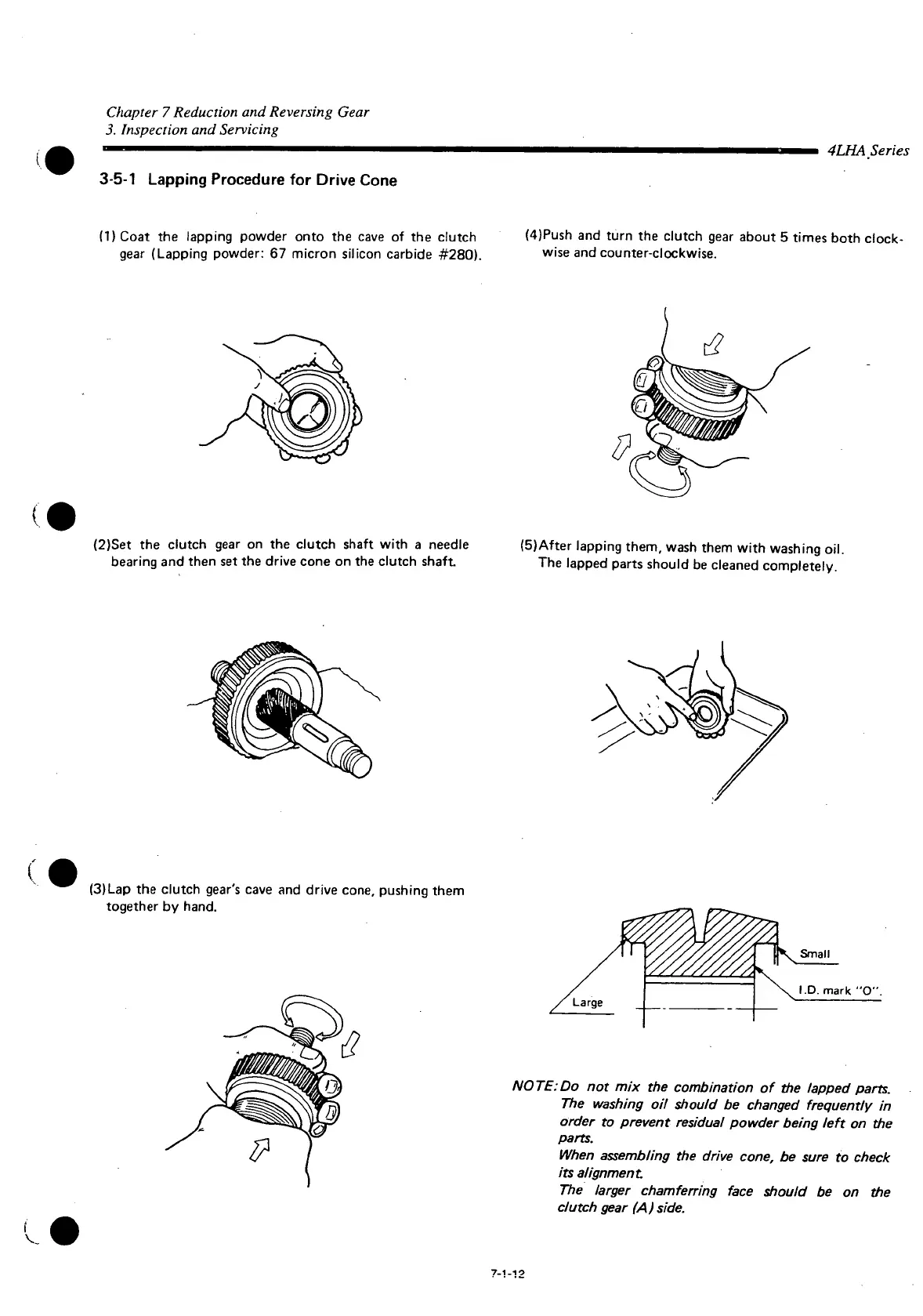

(l)Coat the lapping powder onto the cave of the clutch

gear

(Lapping powder: 67 micron silicon carbide

#280).

(4)Push

and

turn

the clutch gear about 5 times

both

clock-

wise

and counter-clockwise.

(2)Set the clutch gear on the clutch shaft

with

a needle

bearing and then set the drive cone on the clutch shaft

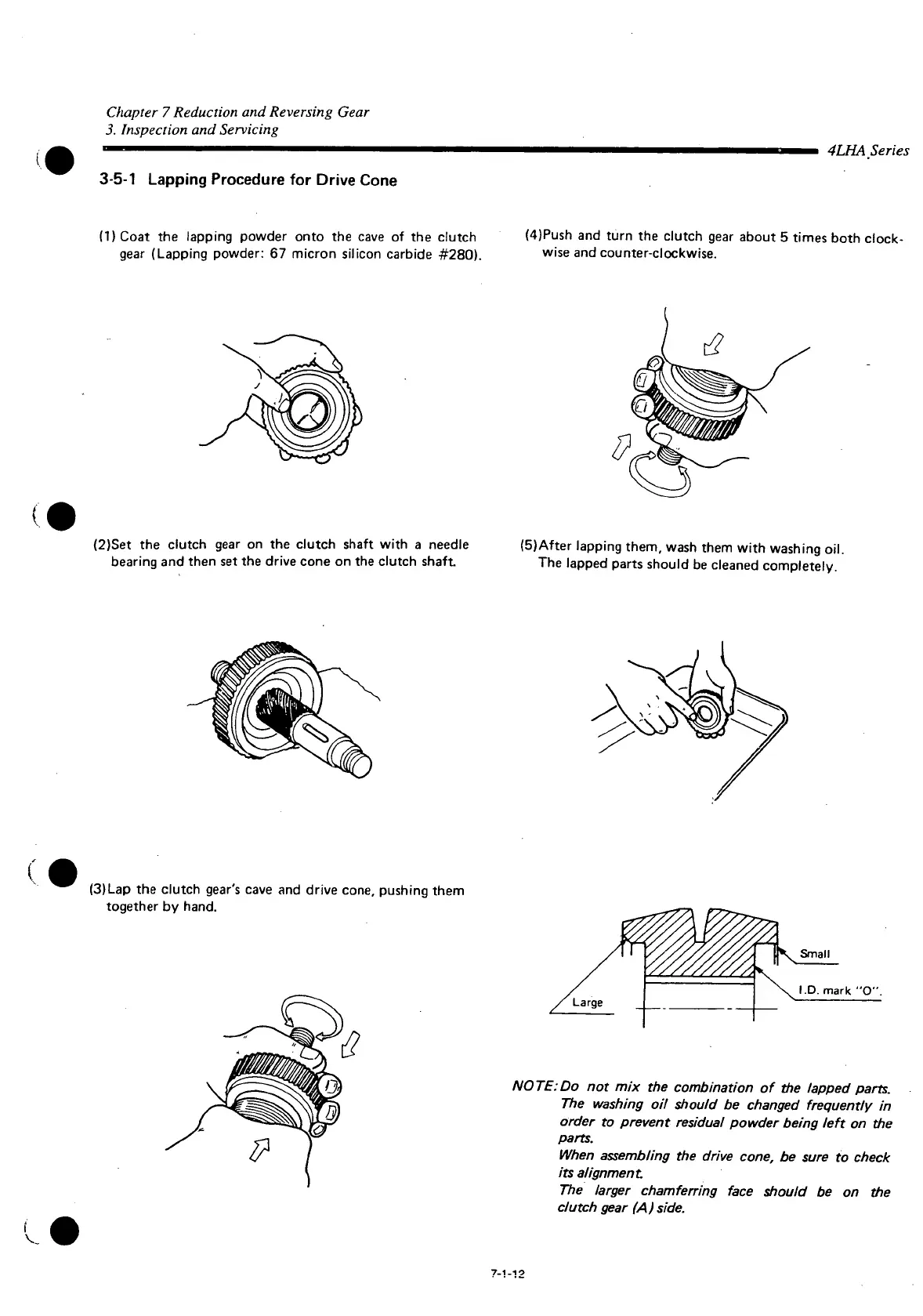

(5)After

lapping them, wash them

with

washing oil.

The

lapped parts should be cleaned completely.

(3)Lap the clutch gear's cave and drive

cone,

pushing them

together by hand.

NOTE:Do not mix the combination of the lapped parts.

The washing oil should be changed frequently in

order to prevent residual powder being left on the

parts.

When assembling the drive cone, be sure to check

its alignment

The larger chamferring face should be on the

clutch gear (A) side.

7-1-12

Loading...

Loading...