Chapter 9 Electrical System

4. Altemator

4LHA Seri,

2) To replace the IC regulator, disconnect the soldered

joint

of the IC regulator and pull out the two bolts. Do

not remove these two bolts except when replacing the

IC regulator.

After repeating the above test, if any diode is found to

be

defective, replace the diode

assembly.

Since

there is

no terminal on the auxiliary diode, check the continuity

between both ends of the diode.

4-11.8

Inspection

and

adjustment

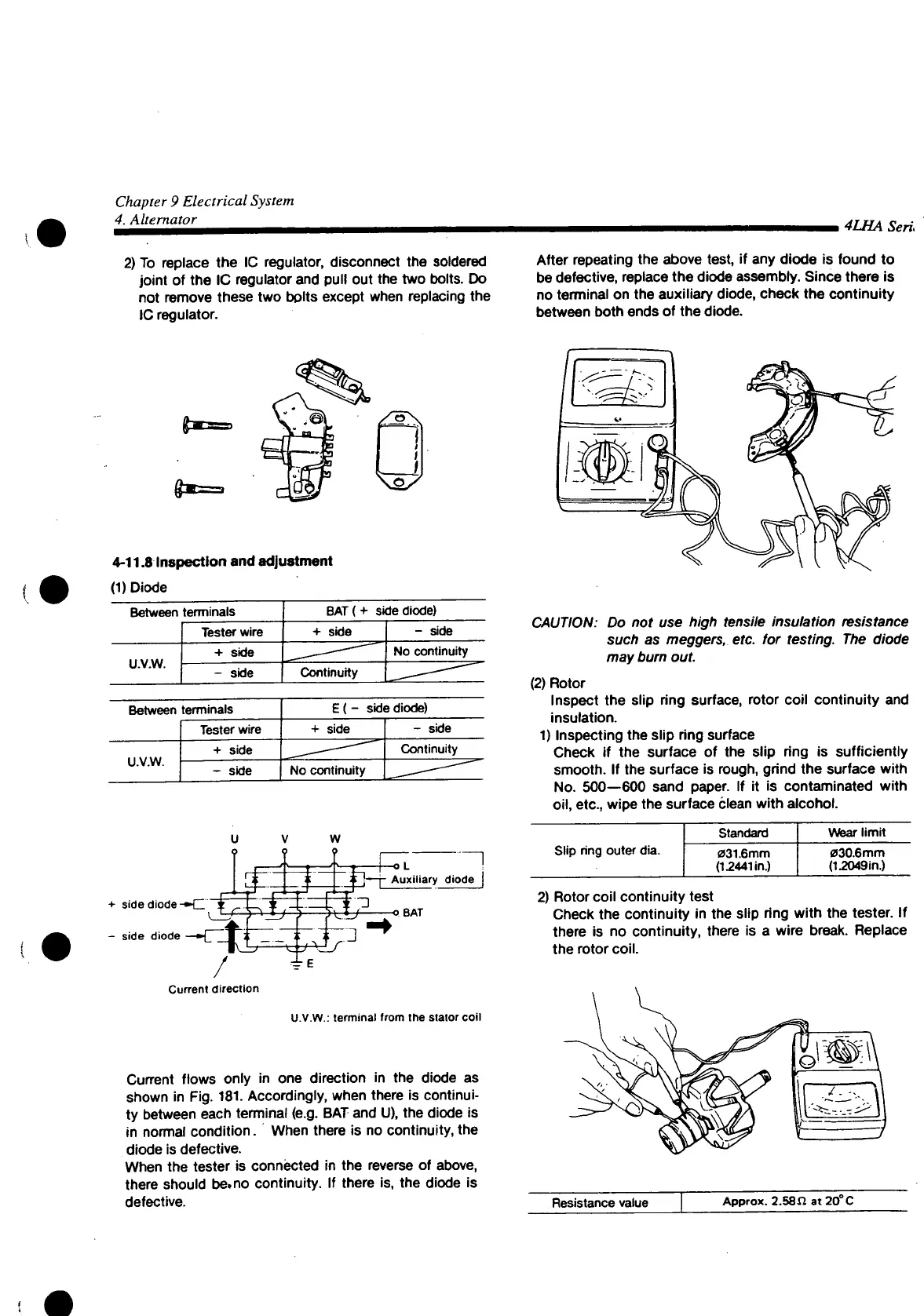

(1) Diode

Between

terminals

BAT

(+ side diode)

Tester

wire + side

- side

u.v.w.

+ side

No

continuity

u.v.w.

- side

Continuity

—^

Between

terminals

E(-

side diode)

Tester

wire

+ side

- side

U.V.W.

+ side

- side

No

continuity

t^oniinuiiy

w

o

-o L

+ side diode-

MM

-j-

Auxiliary diode

-

side

diode

/

Current direction

Jr

E

\J_P

o

BAT

U.V.W.:

terminal from the stator coil

Current flows only in one direction in the diode as

shown in Fig. 181. Accordingly, when there is continui-

ty between each terminal (e.g. BAT and U), the diode is

in normal condition. When there is no continuity, the

diode is defective.

When

the tester is connécted in the reverse of above,

there should be.no continuity. If there is, the diode is

defective.

CAUTION: Do not use high tensile insulation resistance

such as meggers, etc. for testing. The diode

may bum out.

(2) Rotor

Inspect the slip ring surface, rotor coil continuity and

insulation.

1) Inspecting the slip ring surface

Check

if the surface of the slip ring is sufficiently

smooth.

If the surface is rough, grind the surface

with

No.

500—600 sand paper. If it is contaminated

with

oil,

etc., wipe the surface clean

with

alcohol.

Slip

ring outer dia.

Standard

031.6mm

(15441

in.)

Wear

limit

030.6mm

(12049in.)

2) Rotor coil continuity test

Check

the continuity in the slip ring

with

the tester. If

there is no continuity, there is a wire break.

Replace

the rotor

coil.

Resistance

value

Approx.

2.58 Hat 20° C

Loading...

Loading...