66

6.1 PERIODIC INSPECTION

The VS-686SS5 will function longer if it is kept clean, cool and dry, while observing the precautions

listed in Par. 2.3. Check for tightness of electrical connections, discoloration or other signs of

overheating or aging. Use Table 29 as your inspection guide. Before servicing, turn OFF AC main

circuit power and be sure that the CHARGE LED is OFF.

Table 29 Periodic Inspection

Component Check Corrective Action

External Terminals,

Loose screws Tighten.

n

t

ount

ng

o

ts,

Connectors, etc.

Loose connectors Tighten.

Heatsink Build-up of dust and dirt

Blow with dry compressed air of 39.2¢10

4

to

58.8¢10

4

Pa (4 to 6kg¡cm

2

) pressure.

Printed Circuit Board Accumulation of conductive dust or oil.

Blow with dry compressed air of 39.2¢10

4

to

58.8¢10

4

Pa (4 to 6kg¡cm

2

) pressure. If dust and

oil cannot be removed, replace the board.

Cooling Fan

For abnormal noise and vibration.

Whether the cumulative operation time

exceeds 20,000 hours or not.

Replace the cooling fan.

Power Elements Accumulation of dust and dirt

Blow with dry compressed air of 39.2¢10

4

to

58.8¢10

4

Pa (4 to 6kg¡cm

2

) pressure.

Smoothing Capacitor Discoloration or odor Replace the capacitor or inverter unit.

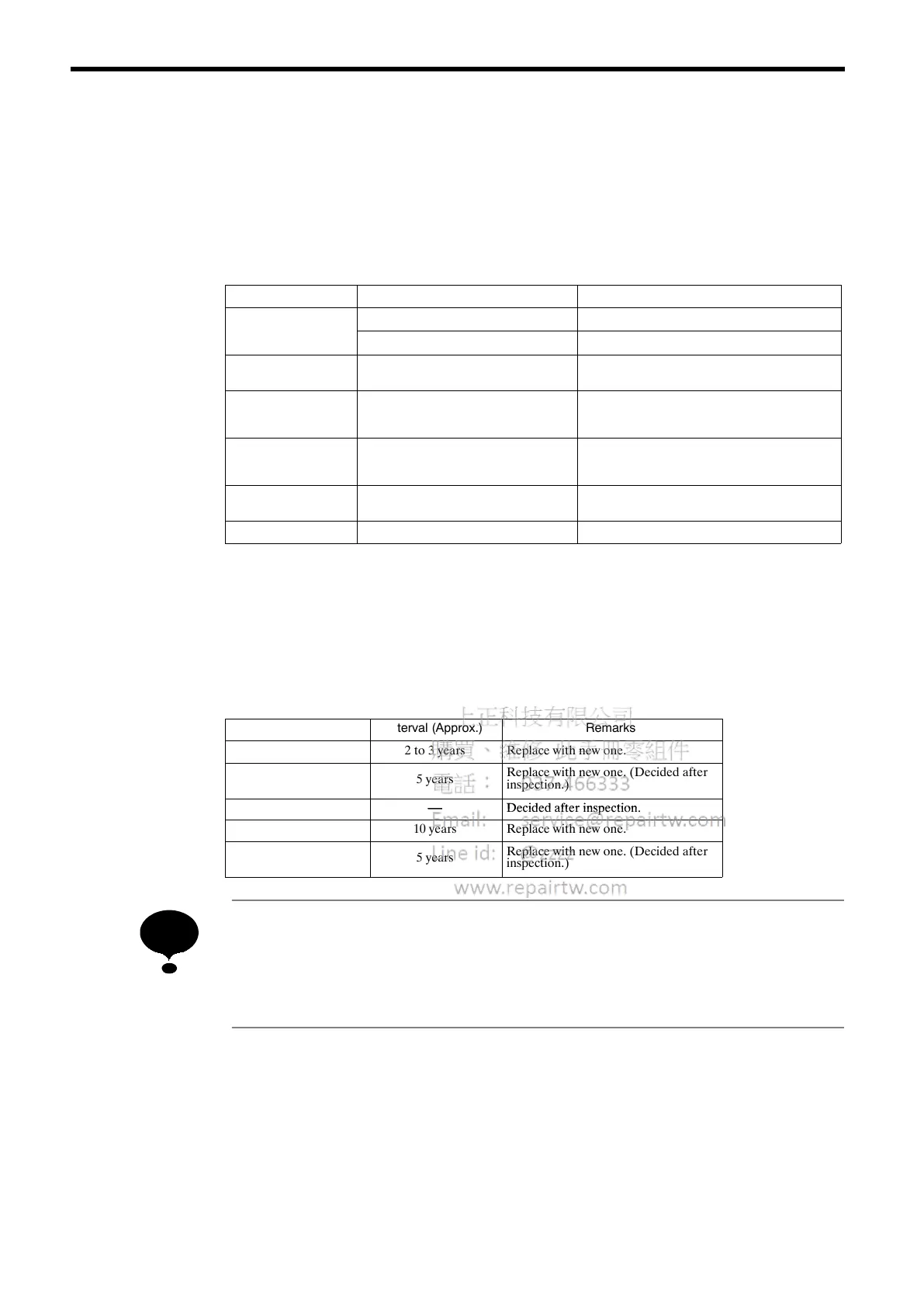

6.2 PARTS REPLACEMENT SCHEDULE (GUIDELINES)

Replace the following parts periodically, for a long, safe, trouble free working life of VS-686SS5.

Table 30 Parts Replacement Schedule

Parts Interval (Approx.) Remarks

Cooling Fan

2 to 3 years Replace with new one.

Smoothing Capacitor

5 years

Replace with new one. (Decided after

inspection.)

Brea

ers or Re

ays

Dec

e

a

ter

nspect

on.

Fuse

10 years Replace with new one.

Aluminum Electrolytic

Capacitor on PC Board

5 years

Replace with new one. (Decided after

inspection.)

Operating conditions are as follows:

Ambient temperature : 30_ C yearly average

Load factor : 80% or below

Operation rate : 20 hours or below /day

NOTE

Loading...

Loading...