TECHNICAL NOTE

MOTION APPLICATION ENGINEERING GROUP

Yaskawa Electric America - 2121 Norman Drive South – Waukegan IL 60085

(800) YASKAWA - Fax (847) 887-7280

11/23/2005 8 of 8 eng/05.055/MCD

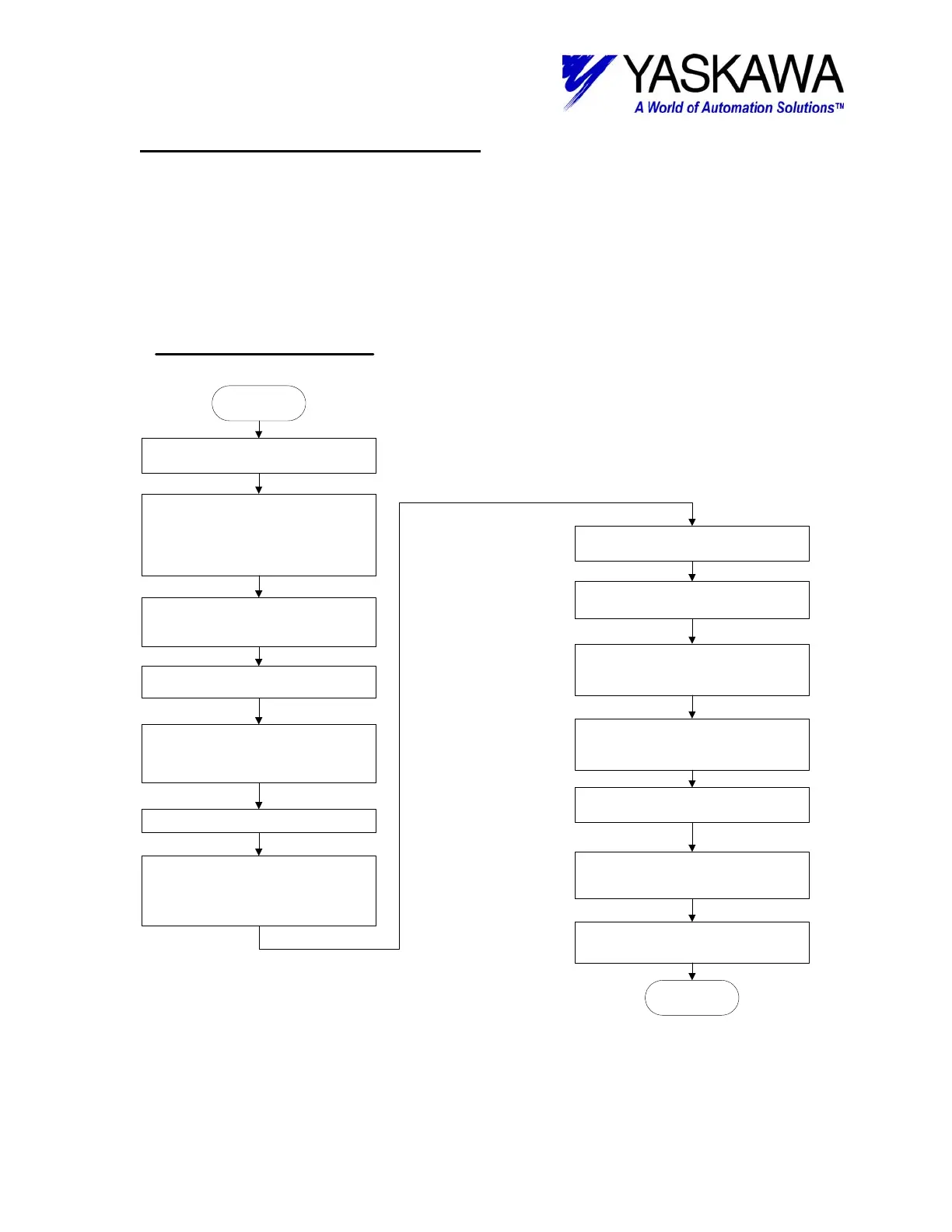

MACHINE INFORMATION GATHERING

In order to implement a structured, reliable and efficient machine control system, requirements of

the machine should be gathered thoroughly in a formal manner to insure details of the system

design or functionality are not overlooked. The sequences of steps for machine information

gathering are shown in the diagram below. Note the sequence of the diagram is in logical

development of the application. Brief descriptions of the information gathering steps and

references to examples of the steps are located in eng.MCD.05.096, MP2000 Best Practices

Information Gathering. Basic Design template example is also referenced in eng.MCD.05.031

Basic Design Template.

START

Machine Block

Diagram

I/O List

Each Pt. Description/Function/

Dependancies

Variable/Tag/Symbol/Constant

requirements

Product Data

1. Max/Min machine speed

2. product sizes

3. product attributes

4. machine speed vs. product size

Identify MachineSequences

Flowchart sequences of Homing,

Production, Fault Recovery, etc.

Machine Timing Diagram

Motion Kernel control block diagram

Fault Diagnostics & Recovery

1. Warning indication

2. Fault indication

Data Storage & Data reporting

requirements

Network Interfacing specifications

1. Physical Layers

2. Protocol Layers

END

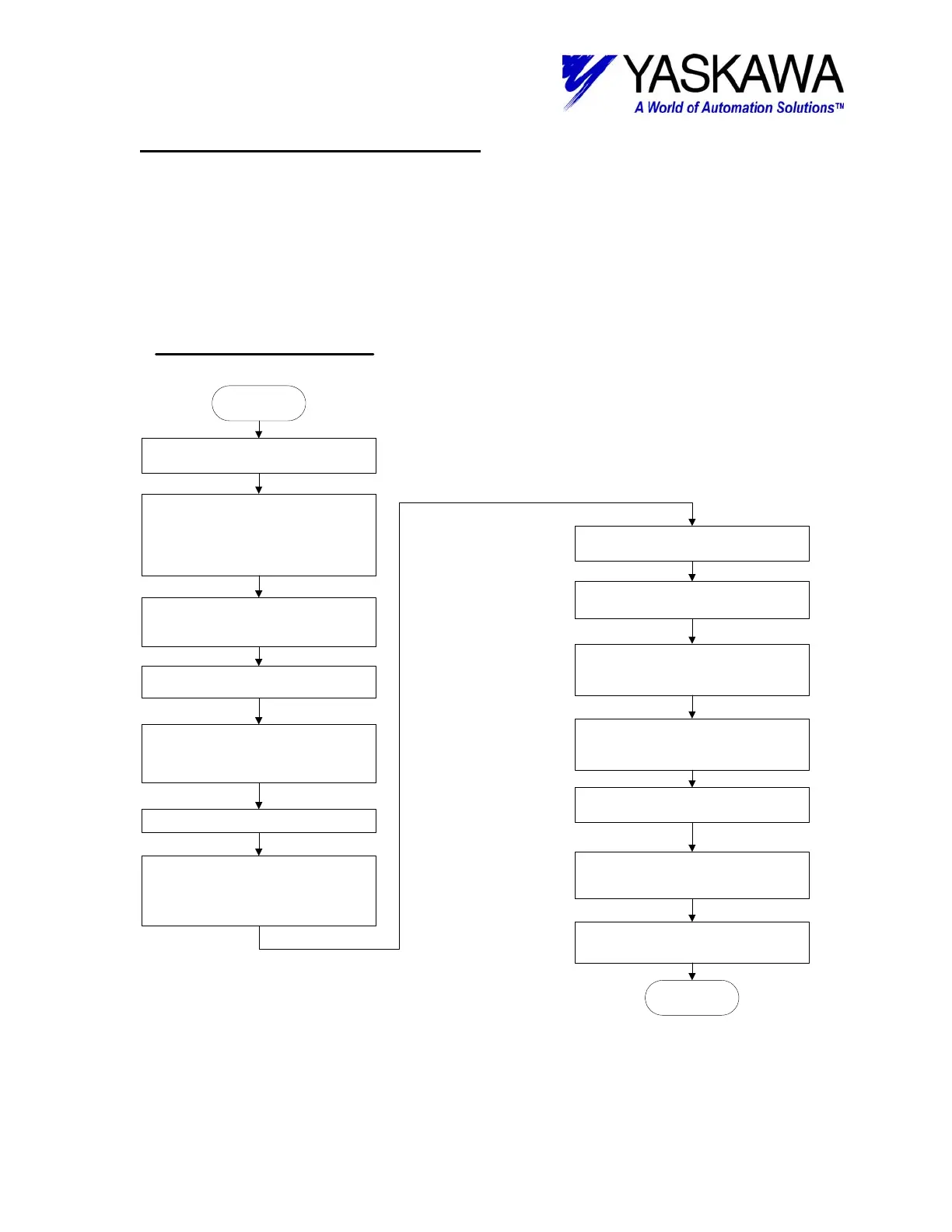

Create Basic Design Document

Basic Design Steps

Axis List

prod. oper. control mode

Machine State Diagram

User Interface

Data setting/selection/input

security levels

Loading...

Loading...