TECHNICAL NOTE

MOTION APPLICATION ENGINEERING GROUP

Yaskawa Electric America - 2121 Norman Drive South – Waukegan IL 60085

(800) YASKAWA - Fax (847) 887-7280

11/23/2005 9 of 9 eng/05.055/MCD

After the requirements and functionality of the machine are documented, the controls

programmer is then able to evaluate the optimum methods of implementing machine and motion

control. The machine block diagram, sequences, timing diagram, and motion kernel control block

diagram will be key in evaluating the programming method to use in the application.

SELECTING PROGRAMMING METHOD

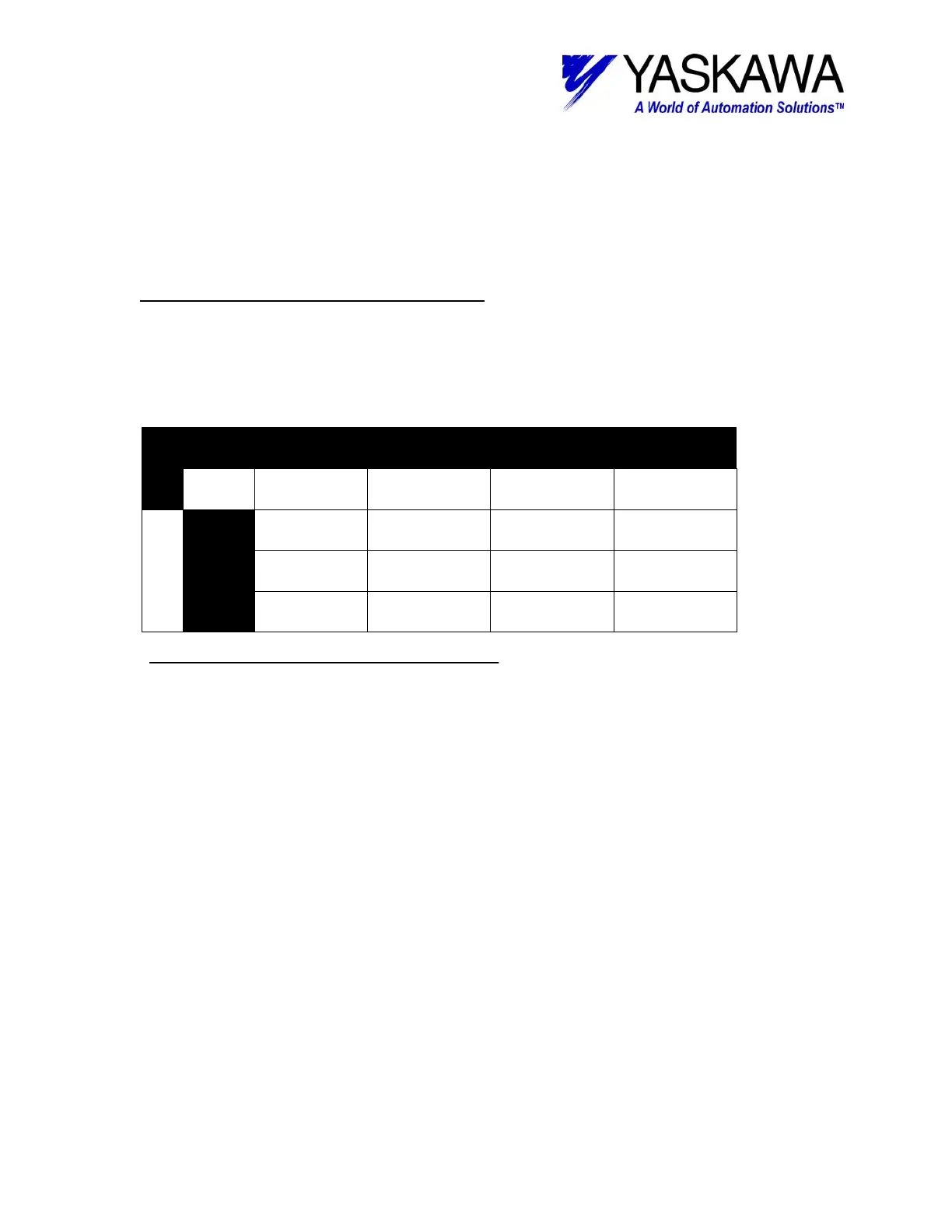

Use the table below to assist in deciding the proper motion control programming implementation

based on the type of machine being controlled and the motion required.

Machine Complexities versus Programming Methods

MACHINE COMPLEXITIES

Point to PointMotion All co-ordinated

scan based profile

generation

Interpolation

Function

Blocks

Motion

Programs

Ladder

O ## X X

O

O

O

O O

**

O

O*

P

r

o

g

r

a

m

M

e

t

h

o

d

It is possible to mix motion programming methods in a controller, but it is recommended

to run a axis by only one method.

KEY

O

Applicable Method

Not Viable

X

**

Any interpolation instructions generates scan based profile

O

##

Axis count dependent

*

Consider method with caution

After evaluating programming methods in relation to machine complexity, the user should

evaluate the individual programming methods based on overall system constraints such as

quantity of axes, programmer expertise, and overall system performance criteria. These

parameters are summarized in the table, Programming Language Grid For High Level Topics on

the following page.

Loading...

Loading...