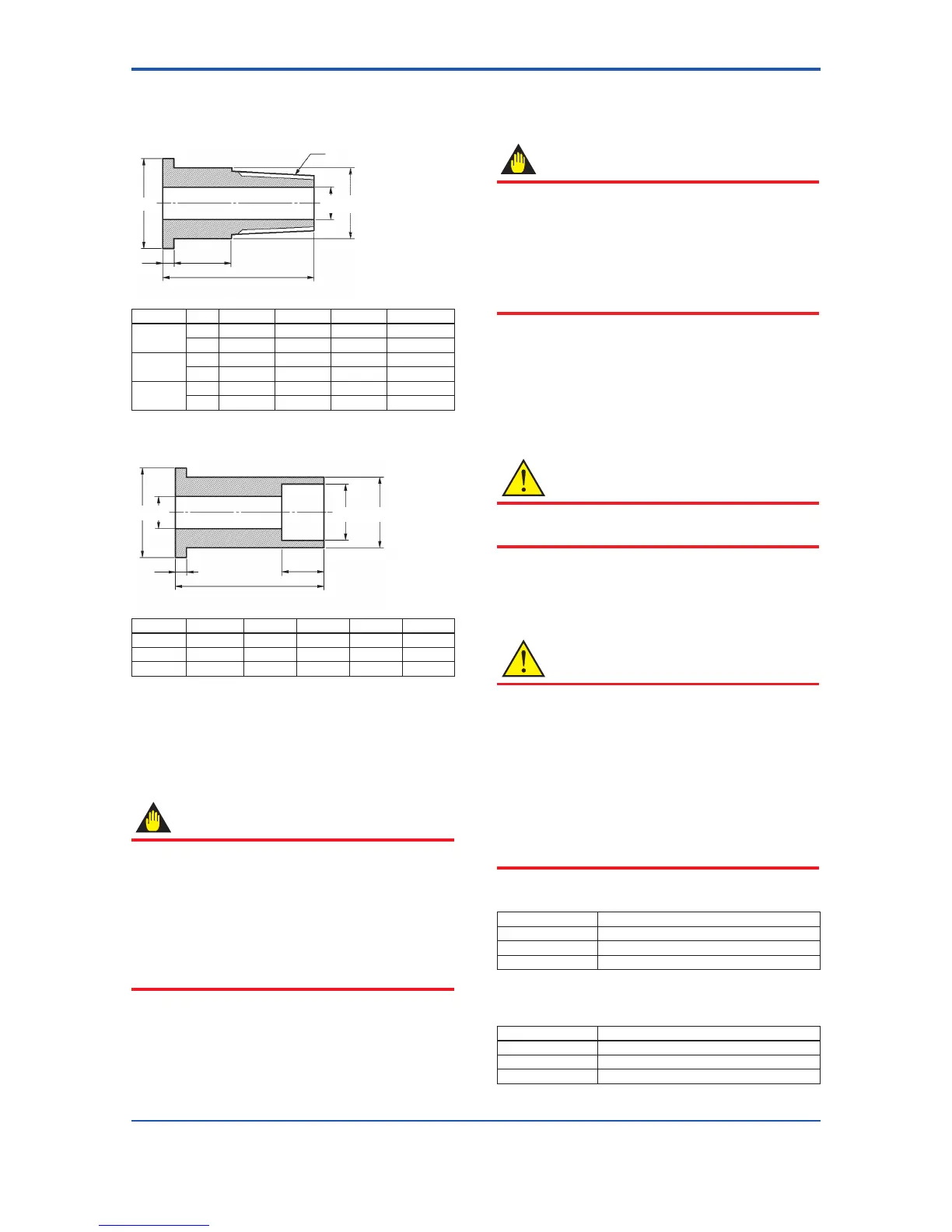

Size Code øA øB øC øD

2.5 (0.1) GUW 22(0.87) 8(0.31) 14.3(0.56) 18.5(0.73)

5 (0.2) GUW 22(0.87) 8(0.31) 14.3(0.56) 18.5(0.73)

10 (0.4) GUW 25(0.98) 10(0.39) 17.8(0.70) 22.5(0.89)

(1) Mounting Direction

Mounttheowmetersothattheowdirectionoftheuid

to be measured is in line with the direction of the arrow

markontheowmeter.

IMPORTANT

If it is impossible to match the direction of the arrow

mark, the direction of the electrical connection can

be changed. Refer to the applicable user’s manuals

which can be downloaded from our website.

Incasetheuidbeingmeasuredowsagainstthe

arrowdirection,changethevaluefrom“Forward”to

“Reverse”attheparameter[J20:FlowDirection]

(refer to Chapter 8).

(2) Connecting Process Piping

Weldorscrewtheconnectionttingstotheprocesspiping.

IMPORTANT

• Besuretopasstheconnectionttingsthroughthe

union joint nuts in advance.

• Whenweldingthettings,payattentiontothe

edge preparation, level differences between the

ttingsandthepiping,andtheweldingcurrentto

avoid deforming the piping or causing stagnation

portionoftheuid.

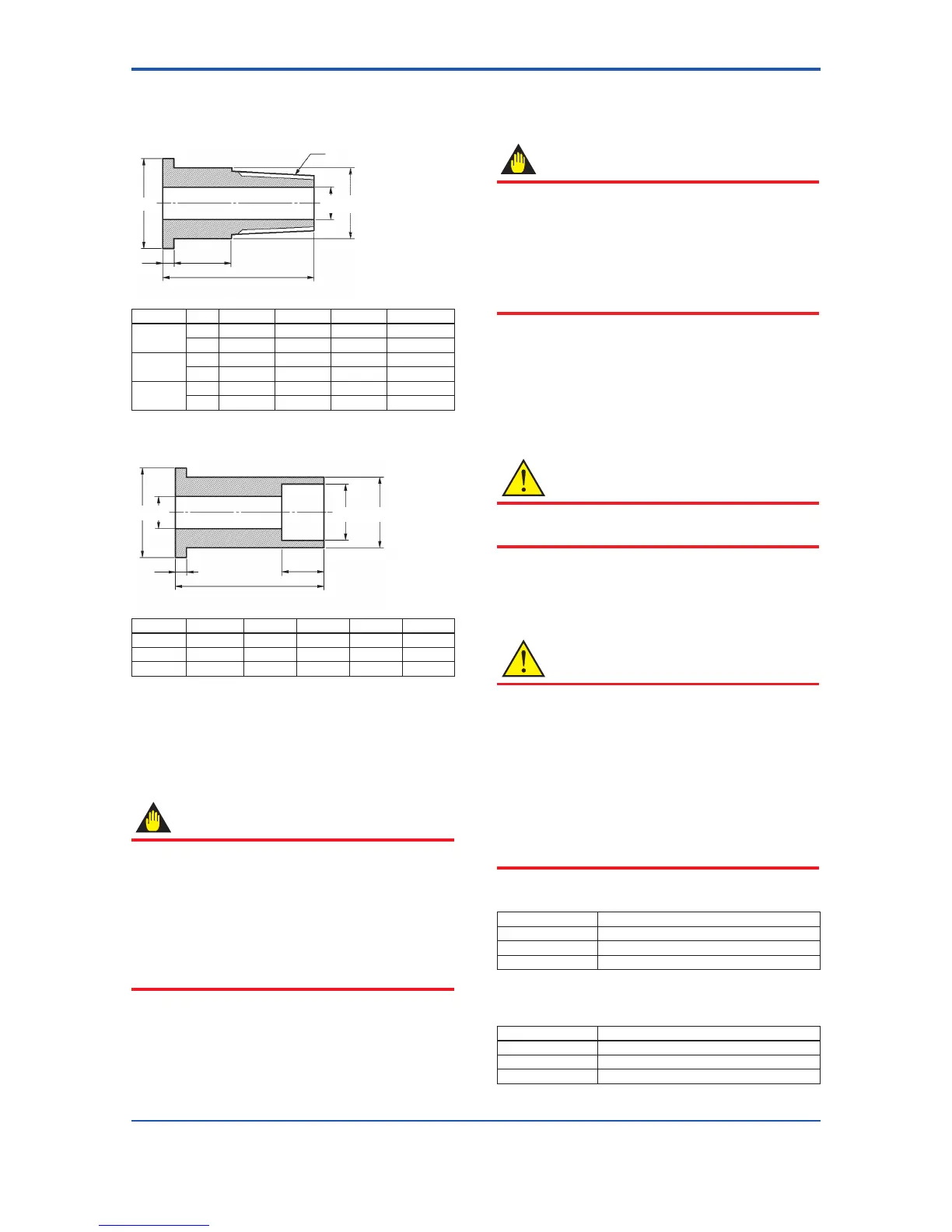

(3) Positioning the Flowmeter

Installtheowmeteronamountingbaseandpositionit

sothatthecenteraxisoftheowtubeisalignedwiththat

of the process piping. Then screw the union joint nuts to

theconnectingportsoftheowmeter.

CAUTION

Ceramics pipes may be damaged if the nuts are

tightened when the center axes are not properly aligned.

(4) Tightening Nuts

Use a torque wrench to tighten the union joint nuts.

CAUTION

Tighten the union joint nuts according to the tightening

torquevaluesinTable3.3.2.Forpermeableuid(such

asnitricacid,hydrouoricacidorsodiumhydrateat

high temperature), tighten the nuts according to the

torque values in Table 3.3.3.

AsthegasketmaterialisuorocarbonPTFE,itis

possible that the nuts may loosen as time passes.

Retighten the nuts if this is the case. Be sure to use

the gasket (thickness is 1.5 mm) which comes with the

owmeter.

Table 3.3.2 Tightening torque values for Union Joint Type

Size mm (inch) Torque (N-m / {kgf-cm} / [in-lbf])

2.5 (0.1) 9 to 12 / {91.77 to 122.4} / [79.66 to 106.2]

5 (0.2) 9 to 12 / {91.77 to 122.4} / [79.66 to 106.2]

10 (0.4) 14 to 18 / {142.8 to 183.5} / [123.9 to 159.3]

Table 3.3.3 Tightening torque values for Union Joint Type

and Permeable Fluids

Size mm (inch) Torque (N-m / {kgf-cm} / [in-lbf])

2.5 (0.1) 11 to 15 / {112.2 to 153} / [97.36 to 132.8]

5 (0.2) 11 to 15 / {112.2 to 153} / [97.36 to 132.8]

10 (0.4) 17 to 23 / {173.4 to 234.5} / [150.5 to 203.6]

Loading...

Loading...