3. Installation

WARNING

Installationofthemagneticowmetermustbe

performed by expert engineer or skilled personnel.

No operator shall be permitted to perform procedures

relating to installation.

Installation Location Precautions

Select the installation location with consideration to the

following items to ensure long-term stable operation of

the instrument.

Ambient Temperature:

Avoid installing the instrument in locations with constantly

uctuatingtemperatures.Ifthelocationissubjectto

radiant heat from the plant, provide heat insulation or

improve ventilation.

Atmospheric Condition:

Avoid installing the instrument in a corrosive atmosphere.

In situations where this is unavoidable, consider ways to

improve ventilation and to prevent rainwater from entering

and being retained in the conduit pipes.

Vibrations or Shocks:

Avoid installing the instrument in a place subject to

shocks or vibrations.

Explosion protected type:

Explosion protect types can be installed in hazardous

areas according to the types of gases for which they

arecertied.SeethedescriptioninChapter10and

“INSTALLATIONANDOPERATINGPRECAUTIONS

FORTIISFLAMEPROOFEQUIPMENT”inthisuser’s

manual.

3.1 Piping Design Precautions

IMPORTANT

Design piping correctly, referring to the following to

preventdamagetoowtubesandtoassureaccurate

measuring.

NOTE

Thischapterdescribestheremoteowtubeasan

example. The same attention must be paid to the

integralowmeter.

(1) Location

IMPORTANT

Installtheowmeterinalocationwhereitisnot

exposed to direct sunlight. The minimum ambient

temperatureislimitedbytheminimumuid

temperatureoftheowtube(thelining).Formore

information,referto“OUTLINE”oftheappropriate

manual which can be downloaded from our website.

Theowmetermaybeusedinanambienthumidity

where the relative humidity ranges from 0 to 100%.

However, avoid long-term continuous operation at

relative humidity above 95%.

(2) Noise Avoidance

IMPORTANT

Theowmetershouldbeinstalledawayfrom

electrical motors, transformers, and other power

sources in order to avoid interference with

measurement.

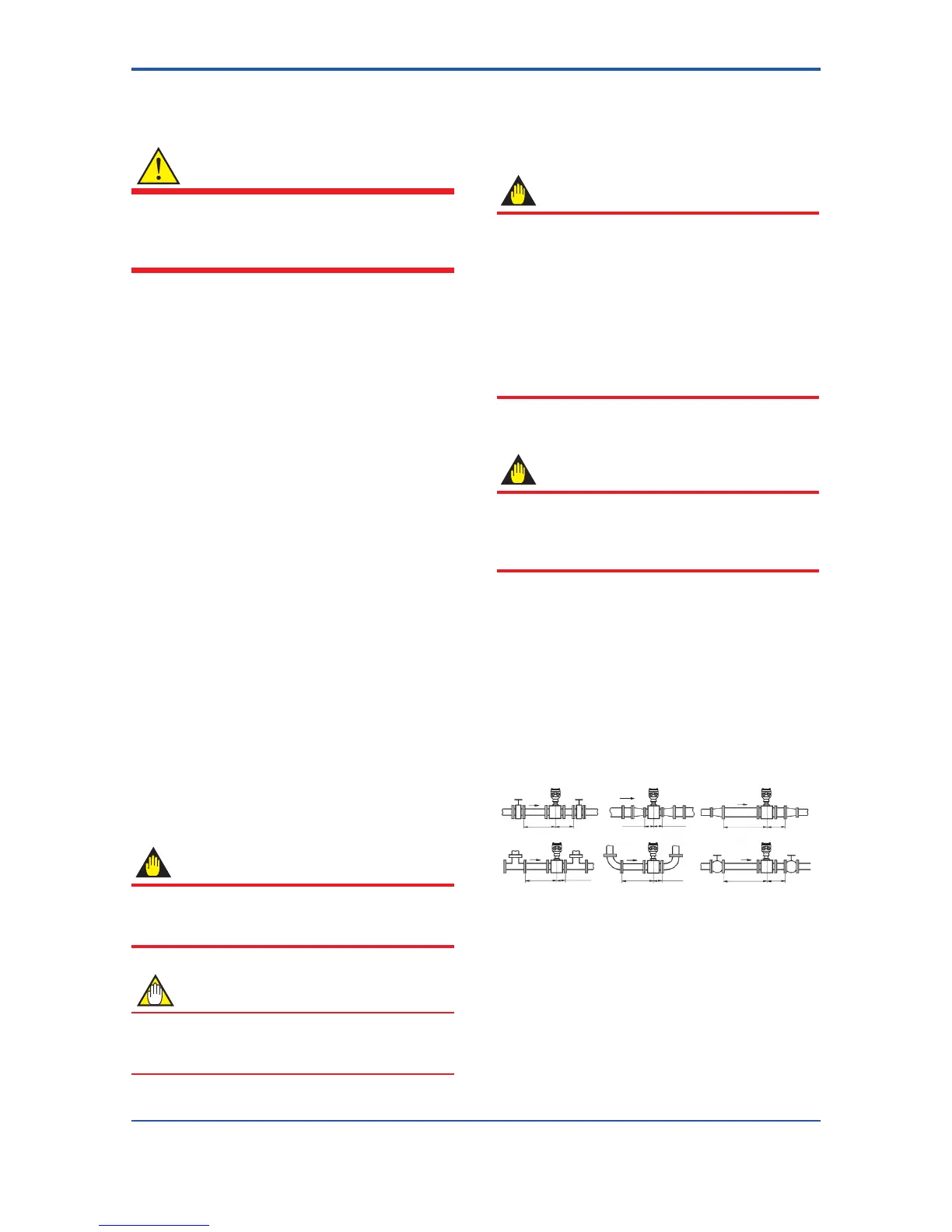

(3) Required Lengths of Straight Runs

Tomaintainaccuratemeasurement,seeJISB7554which

explains the requirements for upstream piping conditions

ofmagneticowmeters.

BasedonJISB7554andourpipingconditiontestdata,

we recommend the piping conditions as shown in the

followinggures.

Wheninstallingtwoormoremagneticowmetersona

single pipe, provide a run of at least 10D between them.

Gate valve

fully open

Reducer

pipe

Expander

pipe

Tee

90-degree bent

Various valves

5D or more

2D

or more

2D

or more

2D

or more

10D or more

10D or more

5D or more

5D or more

0 is allowable. 0 is allowable.

0 is allowable.

0 is allowable.

Figure 3.1.1 Required Lengths of Straight Runs

*1: Do not install anything in the vicinity that may interfere

withthemagneticeld,inducedsignalvoltages,orow

velocitydistributionsoftheowmeter.

*2: A straight run may not be required on the downstream

sideoftheowmeter.However,ifadownstreamvalve

orotherttingcausesirregularityordeviationinows,

provide a straight run of 2D to 3D on the downstream side.

*3: The valves shall be mounted on the downstream side so

thatdeviatedowsdonotoccurintheowtubeandto

avoid startup from an empty condition.

Loading...

Loading...