(5) Long-term Non-use

IMPORTANT

Itisnotdesirabletoleavetheowmeterunused

for a long term after installation. If this situation is

unavoidable,takecareoftheowmeterbyobserving

the following.

Conrmationofsealingconditionsfor

theowmeter

Conrmthattheterminalboxscrewandwiringportsare

well sealed. Equip the conduit piping with drain plugs

or waterproof glands to prevent moisture or water from

penetratingintotheowmeterthroughtheconduit.

Regular inspections

Inspect the sealing conditions as mentioned above, and

the inside of the terminal box at least once a year.

Also, due to rain, etc. when it is suspected that water

mayhavepenetratedintotheinsideowmeterperform

supplementary inspections.

3.2.2 Flowmeter Piping

CAUTION

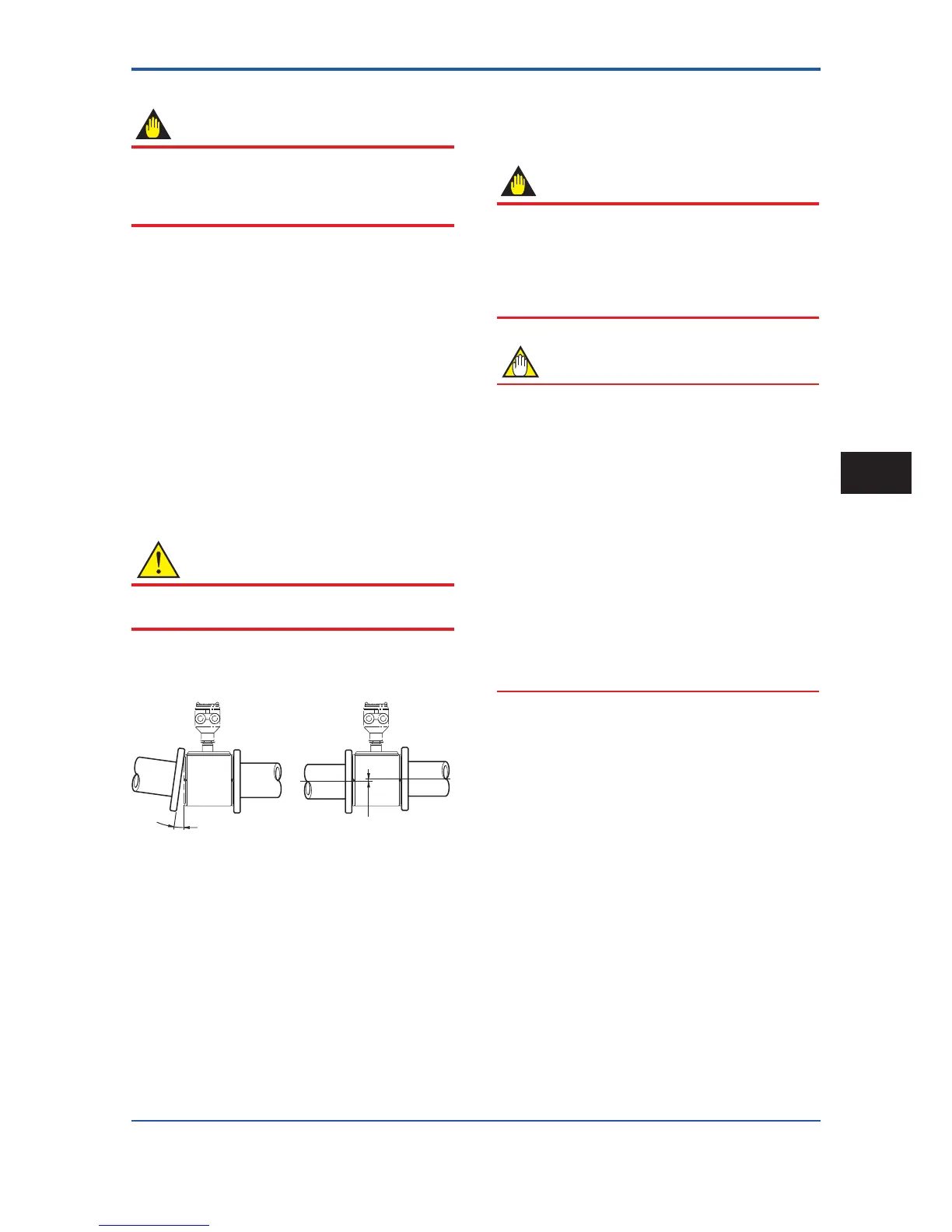

Misaligned or slanted piping can lead to leakage and

damagetotheanges.

(1) Correct any misaligned or slanted piping, and any

gapsthatmayexistbetweenmountingangesbefore

installingtheowmeter(refertoFigure3.2.2).

Slanted

Misaligned

Figure 3.2.2 Slanted and Misaligned Flowmeter Piping

(2) Inside a newly installed pipeline, there may be some

foreign substances such as residue from welding

orwoodchips.Removethembyushingthepiping

beforemountingtheowmeter.Thispreventsthe

lining from being damaged, as well as the occurrence

of erroneous measured signals resulting from foreign

substancespassingthroughtheowtubeduring

measurement.

3.3 Installation of Integral

Flowmeter and Remote

Flowtube

IMPORTANT

Do not forget to insert gaskets from Yokogawa between

pipesandowmeter,whichshallbesuppliedwhenthe

owmeterhasceramicsliningwithnogroundingrings.

In case of grounding rings to be supplied and attached

later, these gaskets shall be inserted between

groundingringsandowmeter.

NOTE

• The tightening torque value to which gaskets must

be tightened varies depending on the type and

external dimensions of the lining and the gasket. In

this section, the tables indicating tightening torque

values include the corresponding gasket types.

The internal diameters of the gaskets are close to

those of the grounding rings (refer to Table 3.3.16).

• ForuidscapableofpotentiallypermeatingPFA

linings(suchasnitricacid,hydrouoricacid,or

sodium hydrate at high temperatures), different

tightening torque values must be applied. The

tables of these torque values is indicated in this

section.

• For replacement models for the earlier ADMAG

or ADMAG AE, the tightening torque values in the

tables can be applied if their process connections,

the lining types, and the nominal sizes are the same.

3.3.1 Nominal Diameter 2.5 mm (0.1 in.) to

10 mm (0.4 in.), Union Joint Type

Ceramics linings with diameters of 2.5 mm (0.1 in.), 5 mm

(0.2 in.), or 10 mm (0.4 in.) are connected using union

joints.WeldorscrewtheconnectingttingsinTable3.3.1

ontothepiping.Theexternaldimensionsofthettings

are shown in the table.

Loading...

Loading...