(4) Maintaining Stable Fluid Conductivity

IMPORTANT

Donotinstalltheowmeterwhereuidconductivity

tends to become uneven. If chemicals are fed near

theupstreamsideofamagneticowmeter,theymay

affecttheowrate’sindications.Toavoidthissituation,

it is recommended that the chemical feed ports be

locatedonthedownstreamsideoftheowmeter.If

it is unavoidable that chemicals must be fed on the

upstreamside,provideasufcientlengthofstraight

run (approximately 50D or more) to ensure the proper

mixtureofuids.

(Correct)

Downstream side

F0302.ai

Figure 3.1.2 Chemical Injection

(5) Precautions for Use of Liquid Sealing

Compounds

IMPORTANT

Care must be taken in using liquid sealing compounds

onthepiping,asitmayhaveanegativeinuence

ontheowindicationsbyowingoutandcovering

the surfaces of an electrode or grounding ring. In

particular, care must be taken if a liquid sealing

compound is used in the case of vertical piping.

(6) Service Area

Select locations where there is adequate space to service

installing, wiring, overhauling, etc.

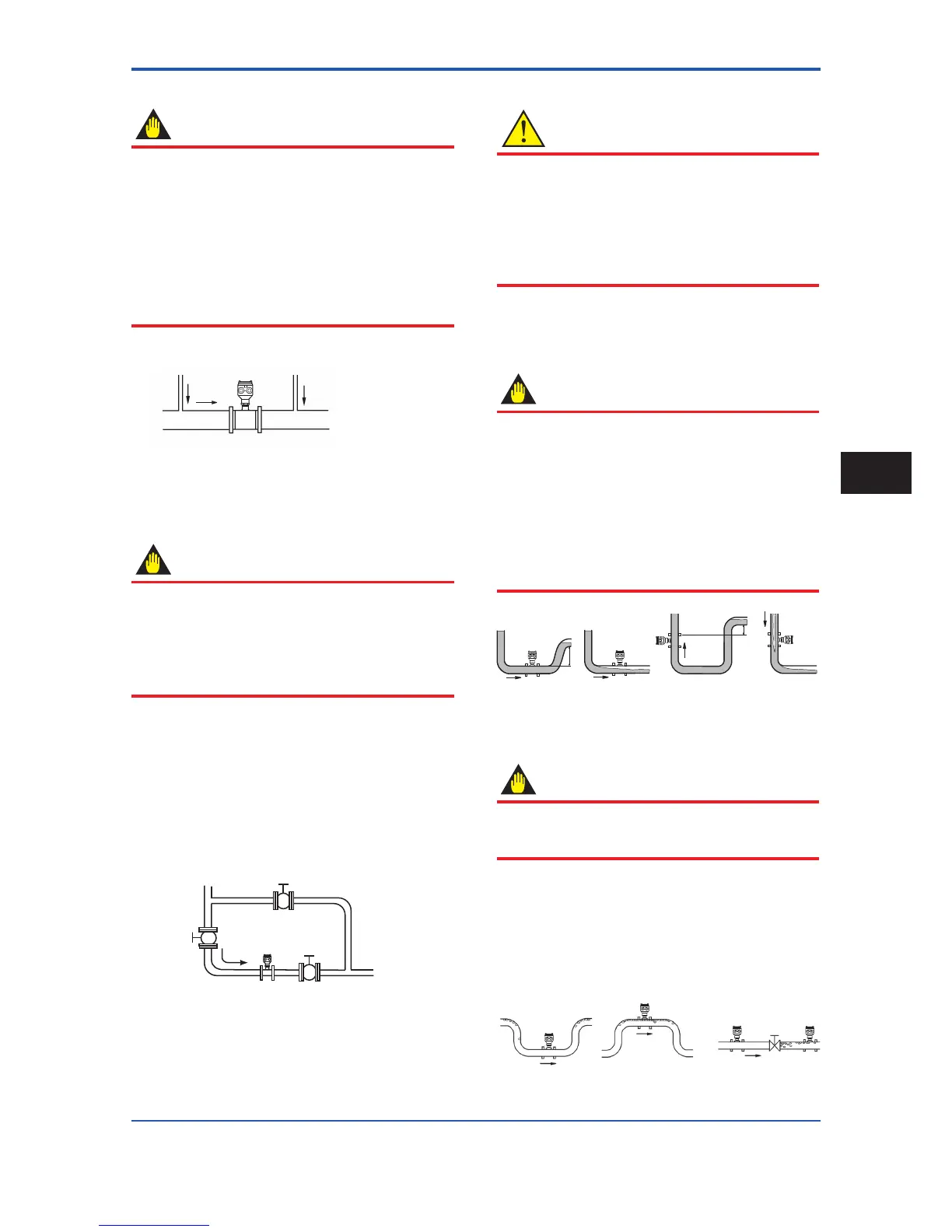

(7) Bypass Line

It is recommended to install a bypass line to facilitate

maintenance and zero adjustment.

Figure 3.1.3 Bypass Line

(8) Supporting the Flowmeter

CAUTION

Donotsecuretheowmeterseparatelytopreventthe

vibrations, shocks, and expansion and contraction forces

ofthepipingfromaffectingit.Fixthepipesrst,then

supporttheowmeterwiththepipes.Withextrasmall-

sizedowmeters(sizes2.5to10mm(0.1to0.4in.)),in

particular,xtheowmeterinparallelwiththepipingona

mounting base.

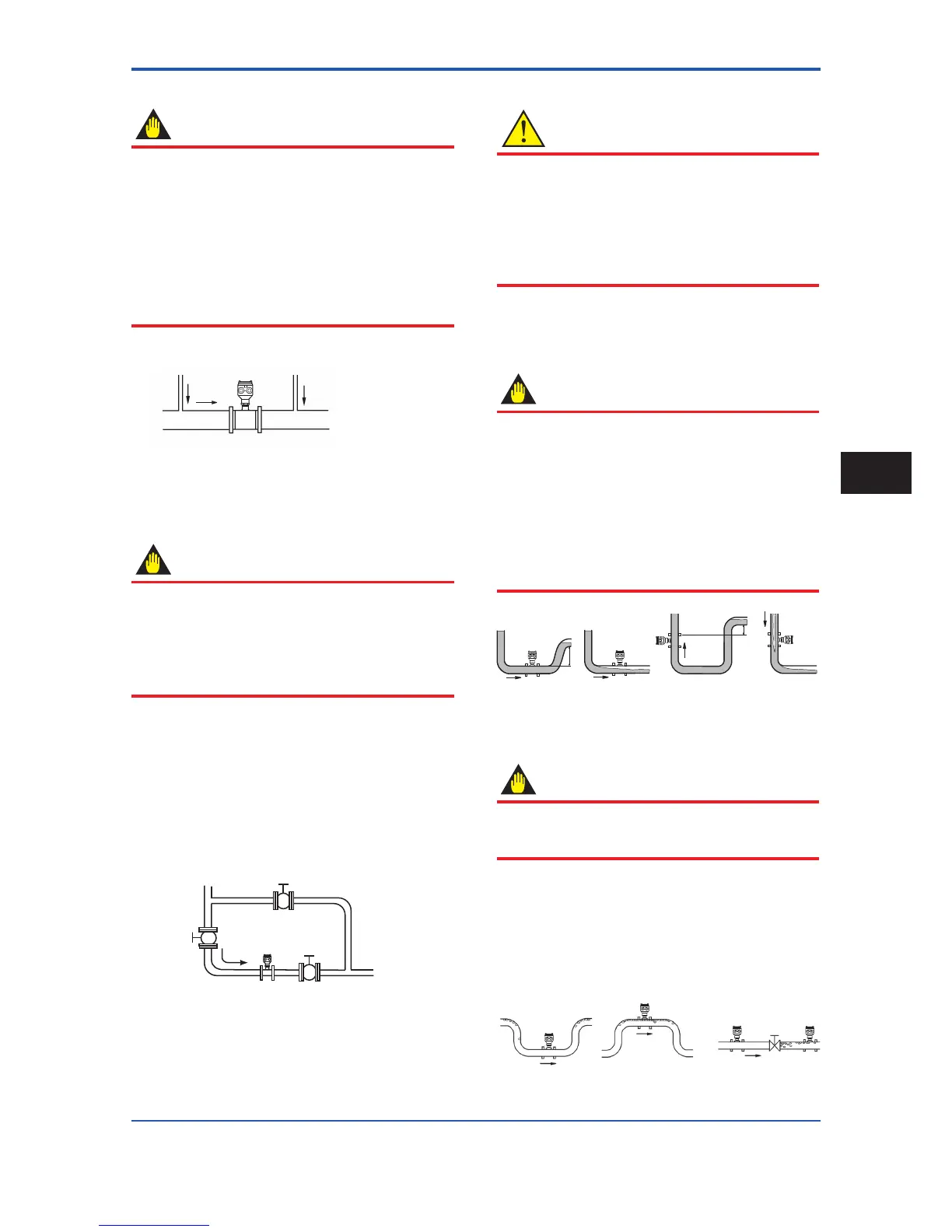

(9) Mounting Positions

Pipesmustbefullylledwithliquids.

IMPORTANT

Itisessentialthatpipesremainfullylledatalltimes,

otherwiseowrateindicationsmaybeaffectedand

measurement errors may be caused.

Piping shall be designed so as to maintain the interior

oftheowtubelledwithuids.

Vertical mounting is effective in such cases as

whenuidstendtoseparateorsolidmattermaybe

precipitated. When employing vertical mounting, direct

theuidsfromthebottomtothetoptoensurethatthe

pipesremainfullylled.

h

h>0

h>0

h

(Incorrect)

(Correct)

(Incorrect)

(Correct)

Figure 3.1.4 Mounting Positions

Avoid air bubbles.

IMPORTANT

Ifairbubblesenterameasurementpipe,owrate

indications may be affected and measurement errors

may be caused.

Incaseswhereuidscontainairbubbles,pipingmust

be designed to prevent them from accumulating in the

measurementpipeofaowtube.

Ifavalveexistsneartheowmeter,trytomountthe

owmeteronthevalve’supstreamsideinorderto

prevent a possible reduction of pressure inside the pipe,

thereby avoiding the possibility of air bubbles.

(Correct)

(Incorrect)

Valve

Figure 3.1.5 Avoiding Air Bubbles

Loading...

Loading...