IM 12D07J01-10E-E

31

5.1. Calibration of the sensor

The conductivity sensors are factory calibrated

traceable to NIST standards. The cell constant

values are indicated on the sensor or on the

integral cable of the sensor. The cell constant

value can be entered directly in the Yokogawa

analyser. The procedure is explained in the

Instruction Manual of the analyser. If the sensor

has been subject to abrasion (erosion or coating)

in the process, re-calibration of the sensor may

be necessary. Refer to the Instruction Manual of

the analyser for a detailed description.

Note: During calibration the temperature

compensation is still active. This means

that the display reading refer to the

default reference temperature (25 °C).

Calibration is normally carried out by measuring

a solution with a known conductivity value at

a known temperature. These solutions are

commercially available. You can make your own

solution by dissolving an amount of salt in water.

Table 6 and 7 show some typical conductivity

values for Sodium Chloride (NaCl) and Potassium

Chloride (KCl) solutions which can be made,

preferably in a laboratory. The tables are derived

from the standards laid down in ‘International

Recommendation No. 56 of the Organisation

Internationale de Métrologie Legale’.

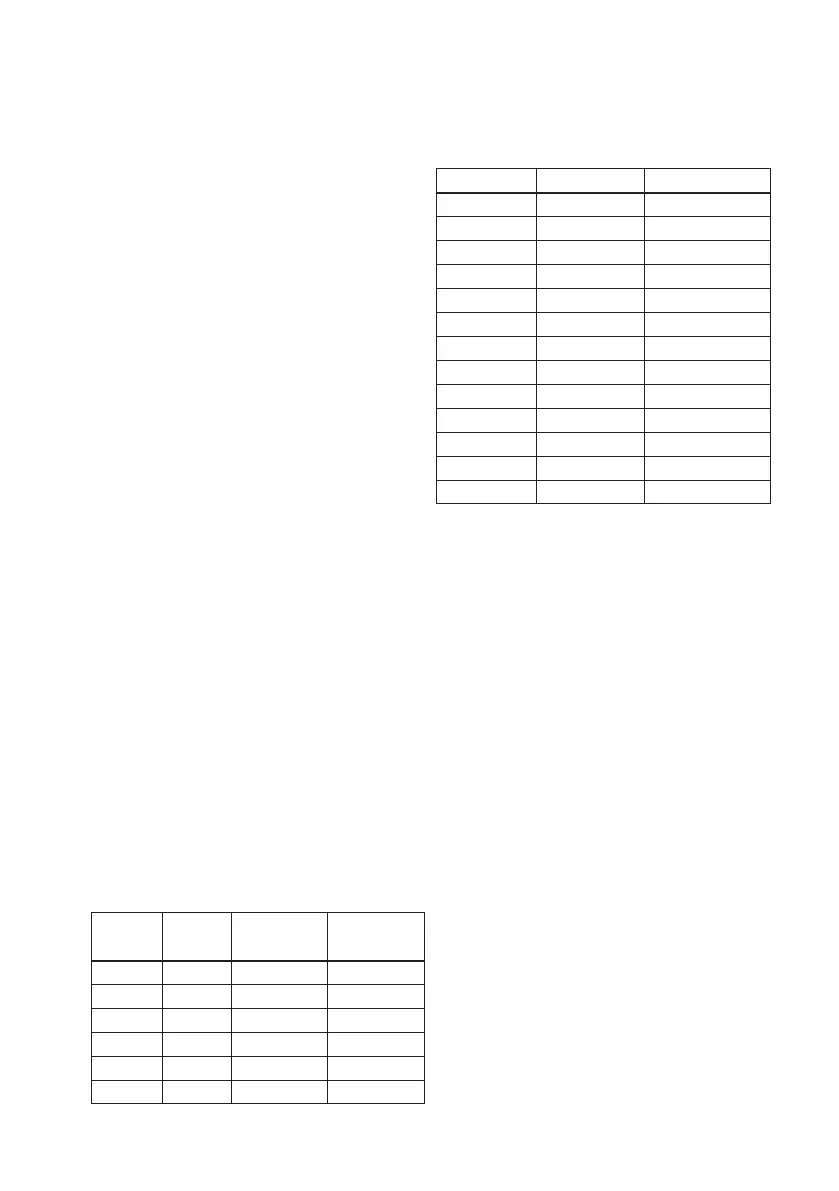

Table 6. KCl values at 25 °C (OIML)

Weigth % molal (m) mg of KCl / Conductivity

kg of solution

0.3 0.001 74.66 0.1469 mS/cm

0.5 0.002 149.32 0.2916 mS/cm

1 0.005 373.29 0.7182 mS/cm

3 0.01 745.263 1.4083 mS/cm

5 0.1 7419.13 12.852 mS/cm

10 1.0 71135.2 111.31 mS/cm

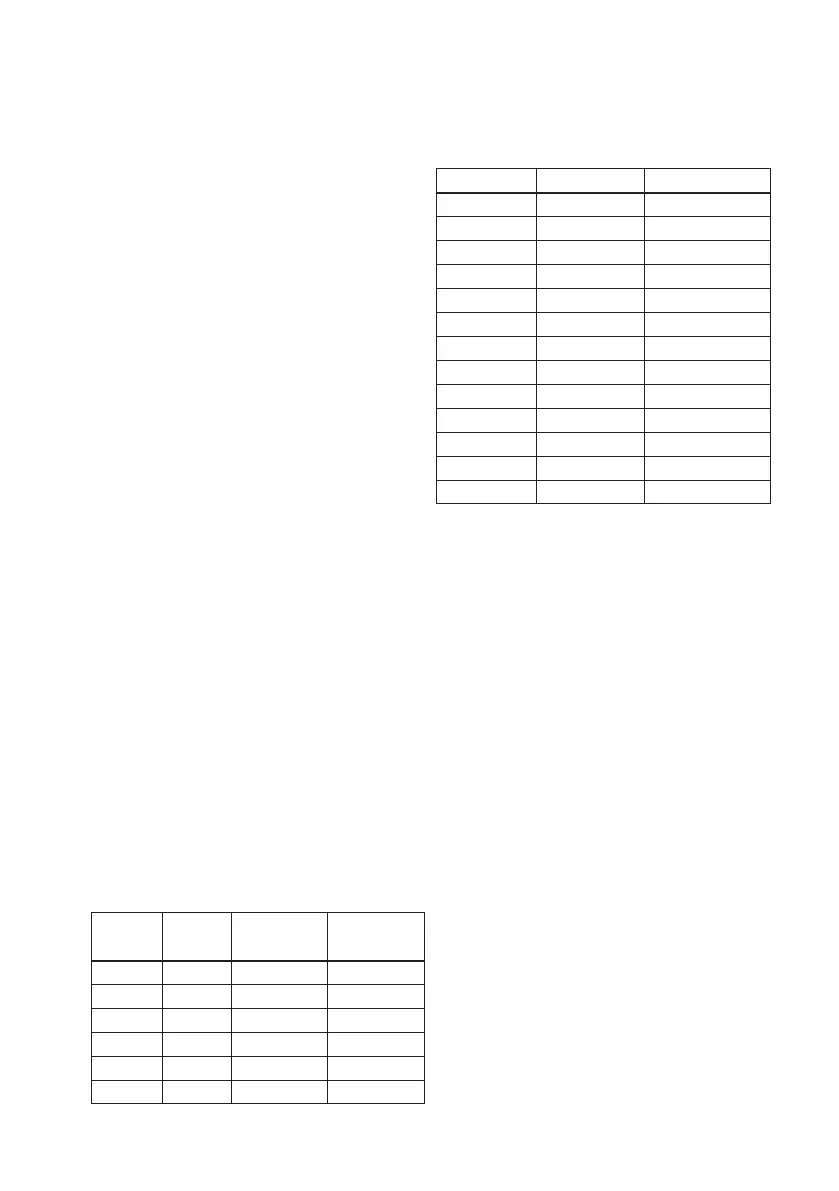

Table 7. NaCl values at 25 °C (IEC 746-1)

Weigth % mg/kg Conductivity

0.001 10 21.4 μS/cm

0.003 30 64.0 μS/cm

0.005 50 106 μS/cm

0.01 100 210 μS/cm

0.03 300 617 μS/cm

0.05 500 1.03 mS/cm

0.1 1000 1.99 mS/cm

0.3 3000 5.69 mS/cm

0.5 5000 9.48 mS/cm

1 10000 17.6 mS/cm

3 30000 48.6 mS/cm

5 50000 81.0 mS/cm

10 100000 40 mS/cm

5.2. Periodic maintenance of the sensor

In general conductivity sensors do not need

much periodic maintenance. In case the sensor

has become fouled, an insulating layer may be

formed on the surface of the electrodes, and

consequently giving a measuring error. Cleaning

the sensor will solve this problem. Effective

cleaning methods are given below:

1. Normal applications: hot water with some

commercially available washing-up liquid.

2. Lime, hydroxides or similar applications:

5 % solution of hydrochloride acid.

3. Organic (e.g. oils, fats) applications: alcohol

or iso-propanol.

4. Algae, bacteria or fungus: solution of

commercially available bleach (hypochlorite).

Note: Read the instructions on the package of

the cleaning agents for safe use.

5. GENERAL CALIBRATION AND MAINTENANCE PROCEDURE

Loading...

Loading...