93D Systems, Inc.

4

REPAIRING A JAMMED EXTRUDER

TOOLS NEEDED

• 2.5 mm Hex Head Driver

• T10 Torx Driver

• Wire Cutters

REPAIRING A JAMMED EXTRUDER PROCEDURE

WARNING: BEFORE SERVICING THESE COMPONENTS, ENSURE YOU ARE WEARING A WELL-GROUNDED

ELECTRO-STATIC DISCHARGE (ESD) STRAP. ESD PROTECTION IS REQUIRED.

WARNING: NEVER PULL ON WIRES TO DISCONNECT THE CONNECTORS. THIS COULD DAMAGE THE WIRES

AND THE CONNECTORS AND VOID THE MANUFACTURER’S WARRANTY.

NOTE: All cartridges except for the one feeding the affected extruder should be properly uninstalled.

The following procedure is intended to provide authorized service providers instructions about how to repair a jammed extruder. For

printers with more than one jammed extruder, follow these instructions for each affected extruder.

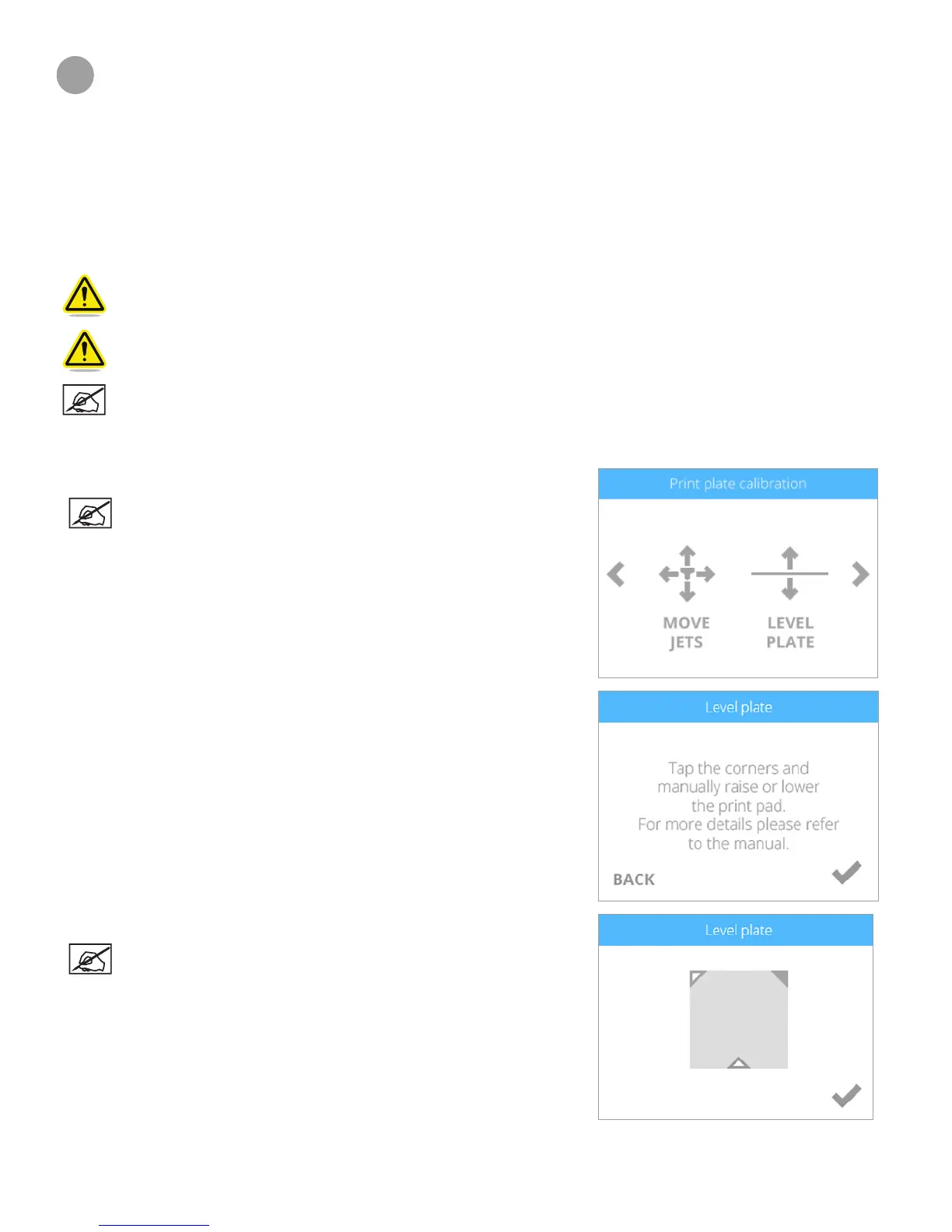

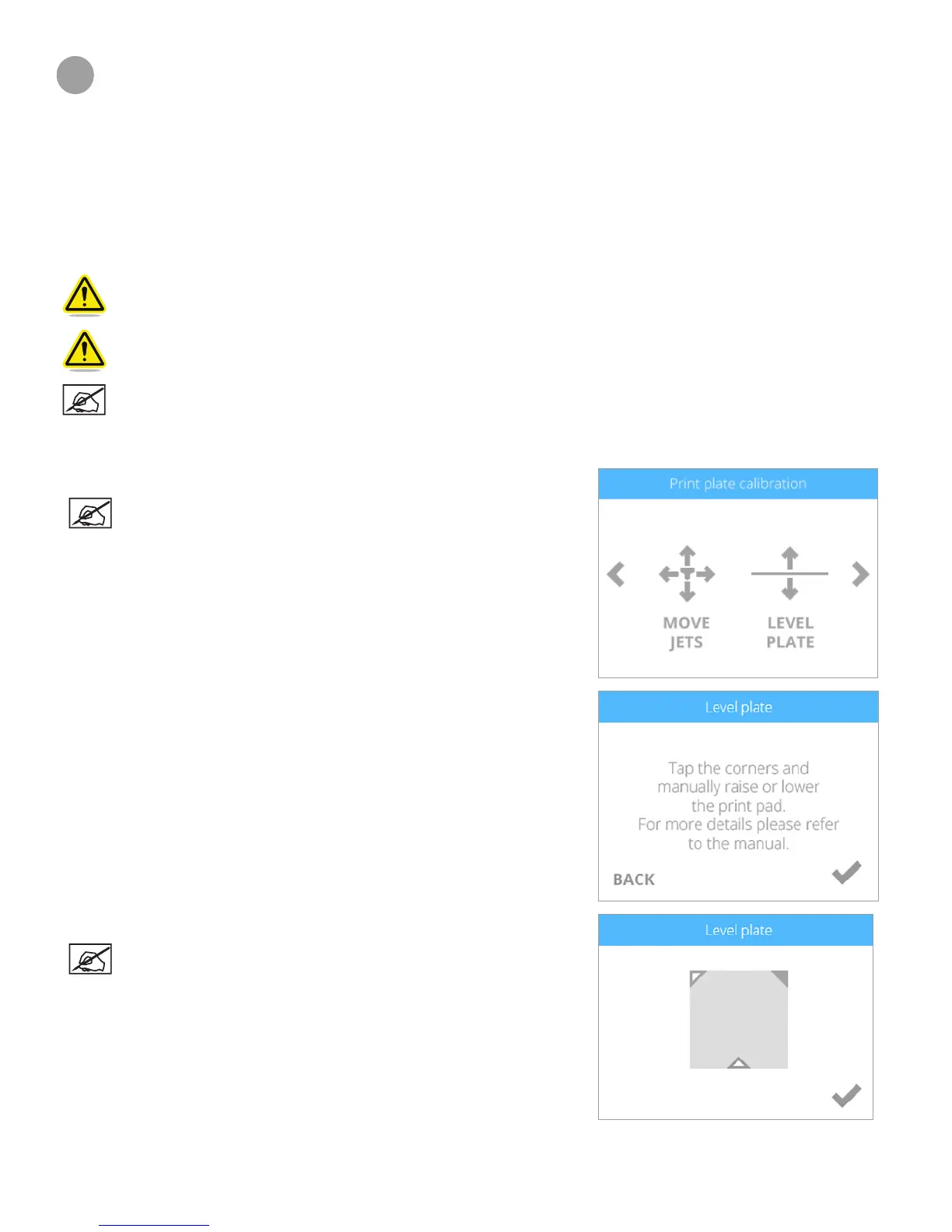

1. Navigate to the Print Plate Calibration screen and select LEVEL PLATE.

NOTE: The print pad will raise and the print jets will maneuver to

the left rear of the printer.

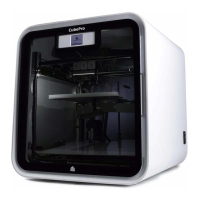

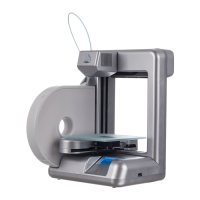

2. Select the upper right corner of the triangle on the touchscreen display.

NOTE: The printheads will move to the right rear corner of the print

pad.

Loading...

Loading...