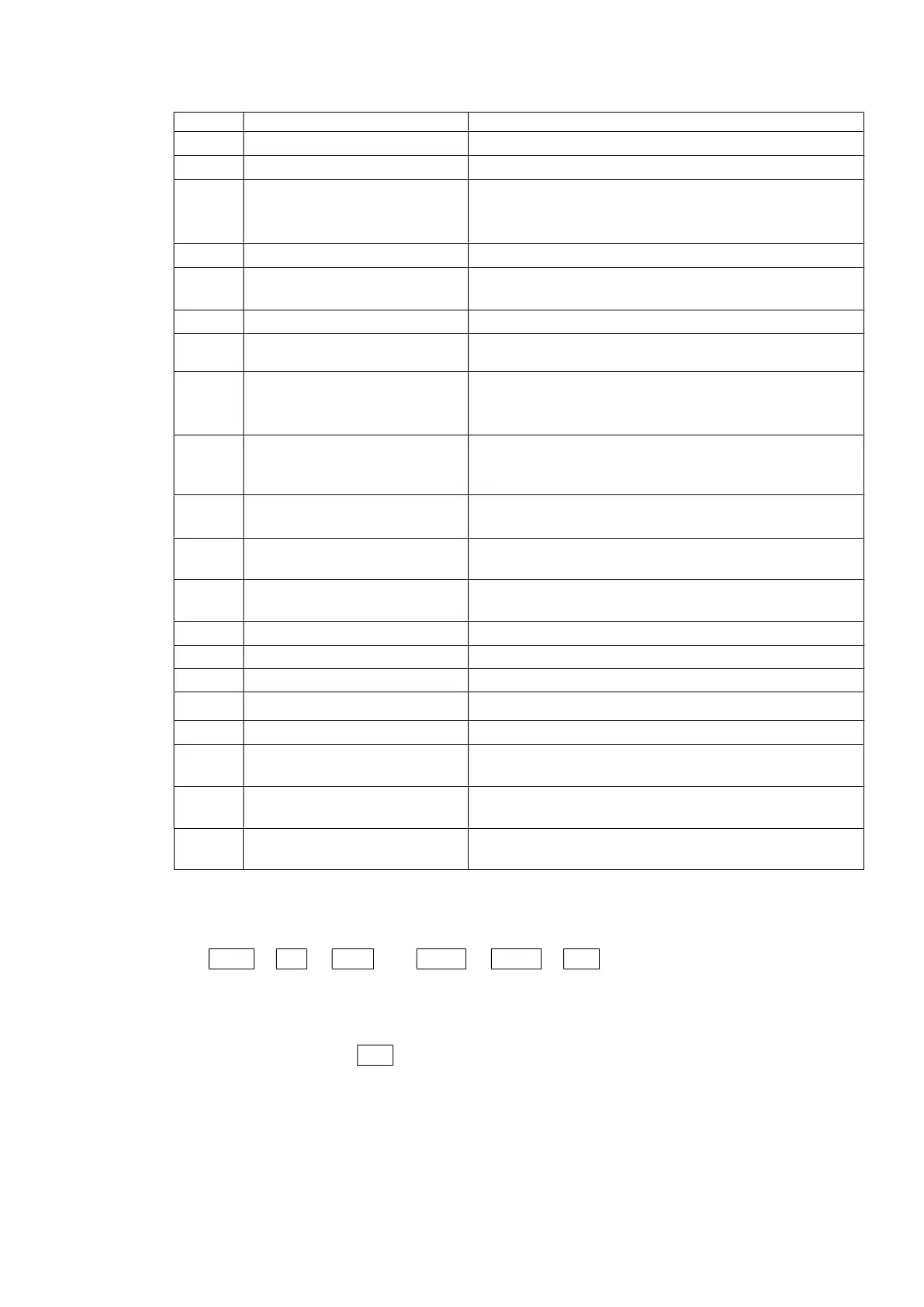

26

7-3-6-2 Error Code

E1 CPU Error 1 CPU was hung-up and restarted

E2 CPU Error 2 CPU clock error

E3 EEPROM Error1 ROM data which normally replaced is broken.

* This error indicates the data of accumulation,

open/close position, PID parameter is broken.

E4 EEPROM Error2 Data loss (Not E3. Mainly settings)

E5 Temperature Sensor Error Temperature sensor were damaged

* Not E15

E6 SW Error SW has been on over 5 minutes

E7 Input signal Error Input signal is out of range

* Input signal is less than 3.91mA

E8 Actuator Setting Error Position keeps MAX for more than 30 seconds while

output of torque motor is 0 (unconforming).

* RA/DA setting is not correct

E9 Output Error Position keeps 0 for more than 30 seconds while

output of torque motor is MAX (unconforming).

* Clogging fixed orifice

E10 TORQ value Error TORQ_MIN or MAX is out of range.

* Occur in A-2 tuning

E11 Shut off Error Input signal is shut off but position does not reach

shut off (±1.0%) in 40 seconds.

E12 Full open Error Input signal is full open but position does not reach

full open (more than 99%) in 40 seconds.

E13 Install Error1 Sensor angle is less than - 50°.

E14 Install Error2 Sensor angle is more than 50°.

E15 Temperature Error Beyond the operating temperature range

E16 PST Error During PST processing, position does not change.

E21 AT Time out Error Could not finished auto tuning in time

E22 Install Error3 Setting for open / close position is less than –50°.

* Occur in A-1 tuning

E23 Install Error4 Setting for open / close position is more than 50°.

* Occur in A-1 tuning

E28 Low Input signal Unable to save settings because input signal is less

than 3.91mA

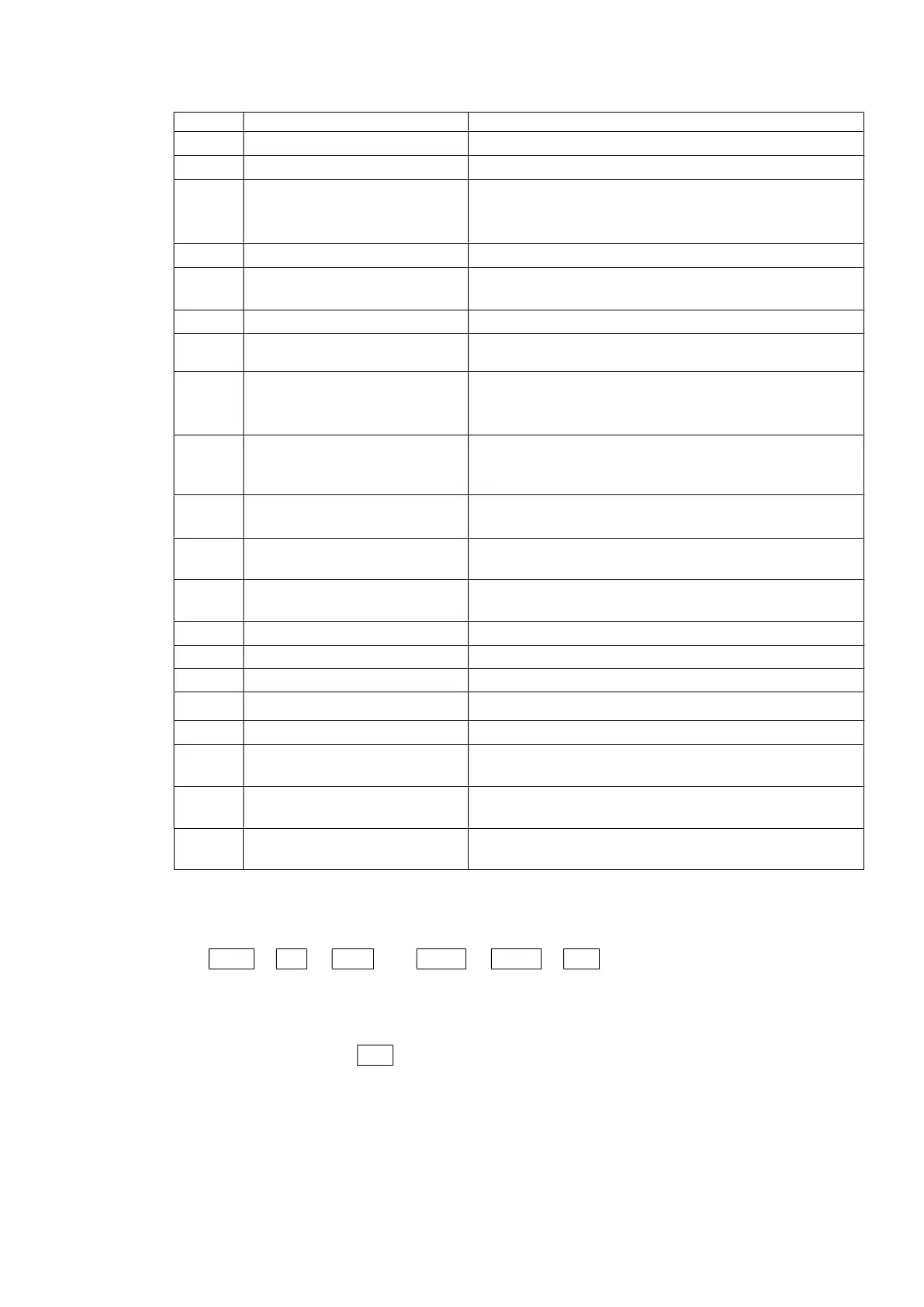

○ Displaying Sequence

To display error code, follow below procedures

LOCK ⏎ LK? ▼ ULK? ⏎ ▼ MANU ▼ WARN ⏎ ERR ⏎

○ Notice

・To display more results of Error, click ▲▼ buttons

・Except E1,3,4 and 16, ERR mark will be disappeared when problem solved

・E1,3,4,16 would not be recovered automatically. Press⏎ button to clear the error code

・「----」means ‘nothing error’

Loading...

Loading...