14

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will grow when it is heated. As the

volume of water grows there will be a corresponding increase in

water pressure due to thermal expansion. Thermal expansion can

cause premature tank failure (leakage). This type of failure is not

covered under the limited warranty. Thermal expansion can also

cause intermittent temperature-pressure relief valve operation:

water discharged from the valve due to excessive pressure build

up. This condition is not covered under the limited warranty. The

temperature-pressure relief valve is not intended for the constant

relief of thermal expansion.

A properly sized thermal expansion tank should be installed on all

closed systems to control the harmful eects of thermal expansion.

Contact a local plumbing service agency to have a thermal expansion

tank installed.

ELECTRICAL

The installation must conform with these instructions and the local/

national code authority having jurisdiction and the requirements

of the power company. In the absence of local/national codes, the

installation must comply with the current editions of the

National

Electrical Code

,

NFPA 70

or the

Canadian Electrical Code CSA C22.1

.

● Before removing any access panels or

servicing the water heater, make sure

the the electrical supply to the water

heater is turned OFF.

Electrical Shock Hazard

● Failure to follow these instructions can

result in personal injury or death.

An electrical ground is required to reduce risk of electrical shock

or possible electrocution. The water heater shall be connected to a

separate grounded branch circuit with over-current protection and an

all pole, full disconnect switch. The water heater shall be grounded

in accordance with Local/National codes.

Voltage applied to the heater should not vary more than +5% to -10%

of the model and rating plate marking for satisfactory operation. See

Model And Rating

(page 10).

All eld wiring to be installed in approved conduit per local Local/

National codes.

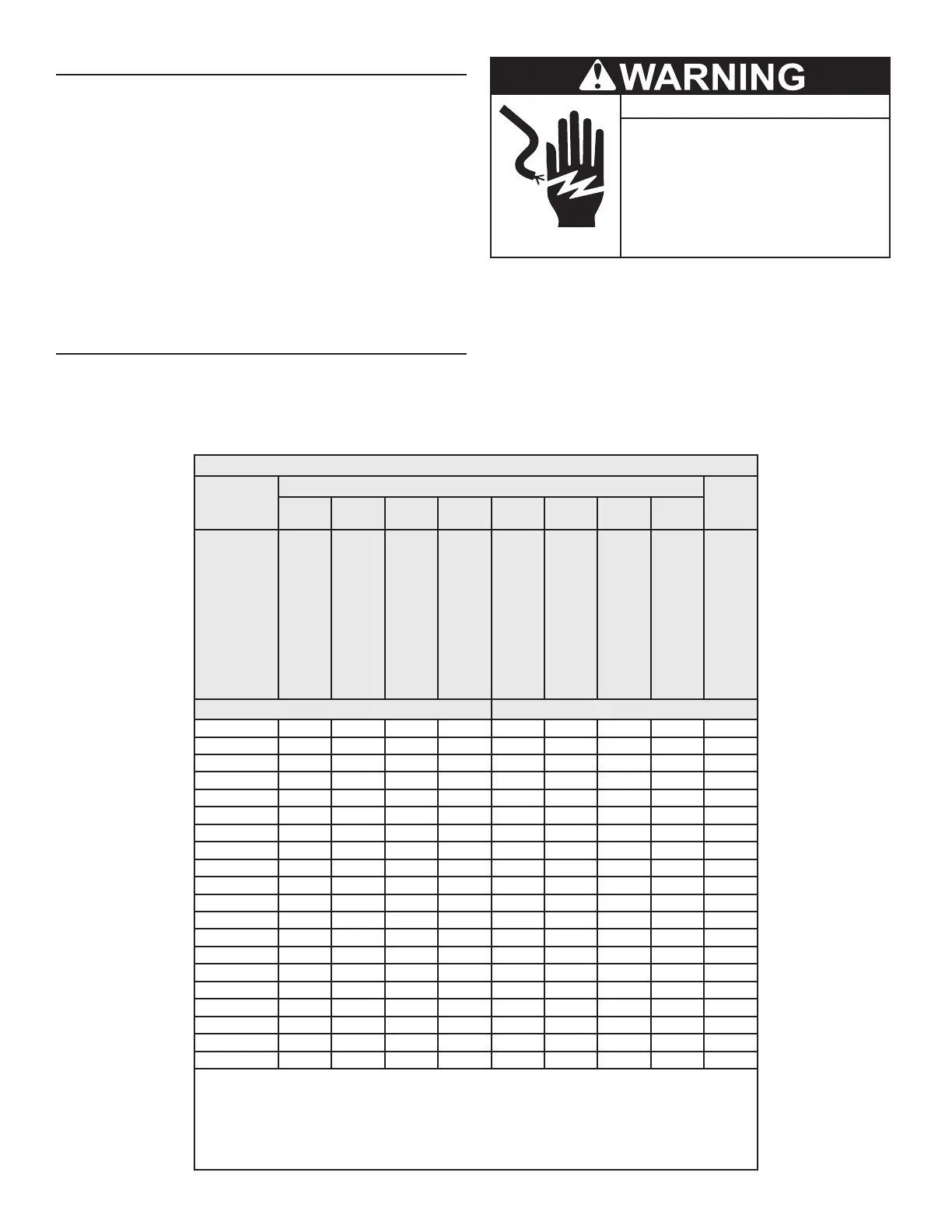

Table 4. Allowable Ampacities of Insulated Conductors

1

Size

Temperature Rating of Conductor

Size

140 °F

(60 °C)

167 °F

( 75 °C)

185 °F

(85 °C)

(194 °F)

(90 °C)

140 °F

(60 °C)

167 °F

( 75 °C)

185 °F

(85 °C)

194 °F

(90 °C)

AWG MCM

Types

RUW,

TTW,

and UF

Types

FEPW,

H,

RHW,

RUH,

HW,

THWN,

XHHW,

USE,

and

ZW

Types

V, and

MI

Types

TA,

TBS,

SA,

AVB,

SIS,

EP

2

,

FEPB

2

,

RHH

2

,

THHN

2

,

and

XHHW

2,

3

Types

RUW,

TTW,

and UF

Types

RH,

RHW,

RUH,

THW,

THWN,

XHHW,

and

USE

Types

V, and

MI

Types

TA,

TBS,

SA,

AVB,

SIS,

RHH

2

,

THHN

2

,

and

XHHW

2,

3

AWG

MCM

Copper Aluminum or Copper-Clad Aluminum

18 .... .... .... 21 .... .... .... .... ....

16 .... .... 22 22 .... .... .... .... ....

14 15 15 25 25 .... .... .... .... ....

12 20 20 30 30 15 15 25 25 12

10 30 30 40 40 25 25 30 30 10

8 40 45 50 50 30 40 40 40 8

6 55 65 70 70 40 50 55 55 6

4 70 85 90 90 55 65 70 70 4

3 80 100 105 105 65 75 80 80 3

2 115 120 120 75 90 95 95 2

1 130 140 140 100 110 110 1

0 150 155 155 120 125 125 0

00 175 185 185 135 145 145 00

000 200 210 210 155 165 165 000

0000 230 235 285 180 185 185 0000

250 255 270 270 205 215 215 250

300 285 300 300 230 240 240 300

350 310 325 325 250 260 260 350

400 335 360 360 270 290 290 400

500 380 405 405 310 330 330 500

1. Not more than three conductors in raceway, cable, or earth (directly buried), based on ambient temperature of

86°F (30°C).

2. +The load current rating and the over-current protection for these conductors shall not exceed 15 amperes

for 14 AWG. 20 amperes for 12 AWG and 30 amperes for 10 AWG copper; or 15 amperes for 12 AWG and 25

amperes for 10 AWG aluminum and copper-clad aluminum.

3. *For dry locations only. See 167 °F (75°C) column for wet locations.

Table taken from the

National Electric Code, NFPA 70

(United States))

Printed on 5/6/2022 7:17 AM CT

Loading...

Loading...