59

Condensate drain trapping and piping should

conform to all applicable governing codes.

Heating Coils

One or two row hot water and steam heating

and preheating coils can be factory installed.

All valve controls for heating operation are

field supplied and field installed. Hot water

and steam coil connections are spun copper

tube.

Water coils should not be subjected to

entering air temperatures below 38°F to

prevent coil freeze-up. If air temperature

across the coil is going to be below this

value, use a glycol solution to match the

coldest air expected.

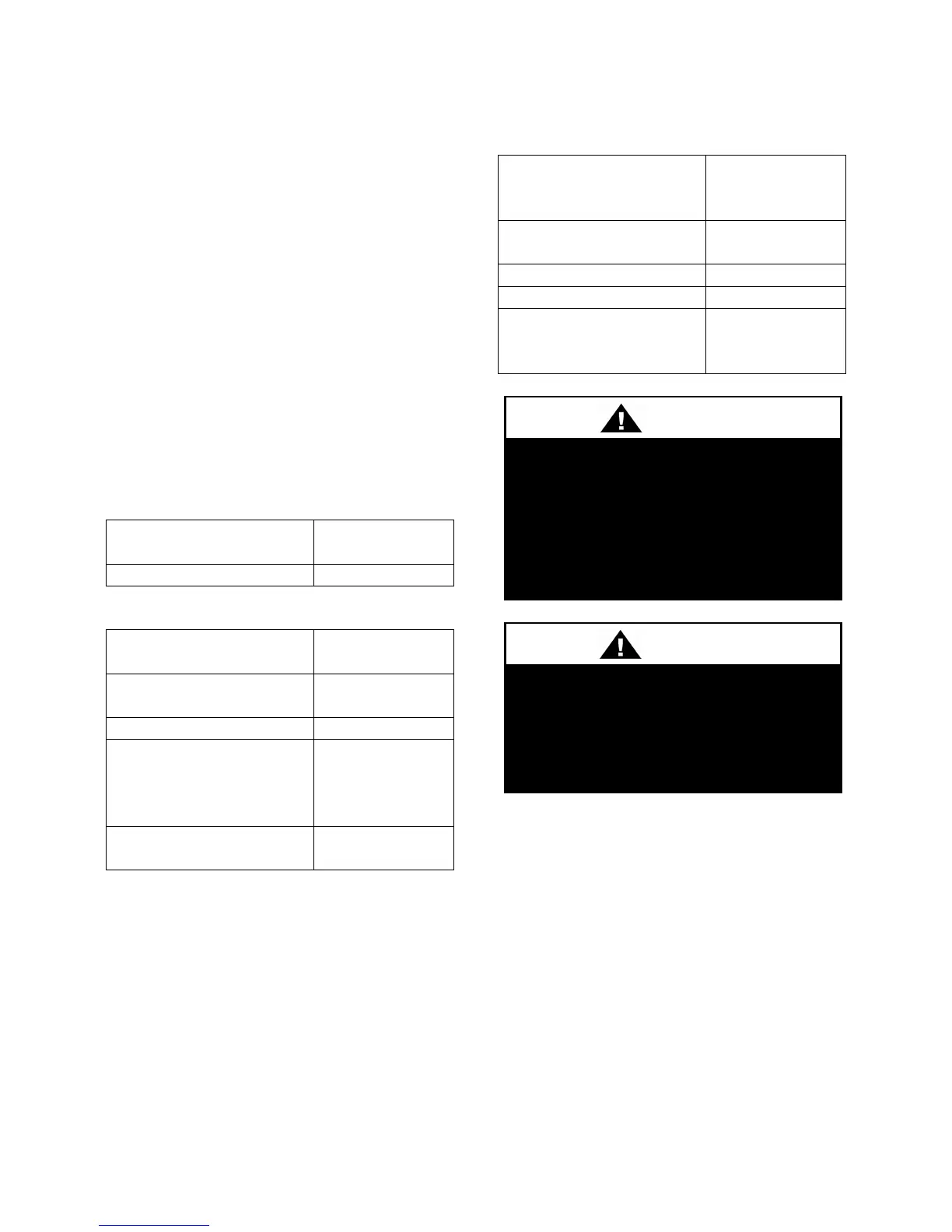

Table 20 - Steam Coil Connection Sizes

Model (RN-)

Steam Coil

Connection Size

Table 21 - Hot Water Coil Connection Sizes

Model (RN-)

Hot Water Coil

Connection Size

006, 007, 008, 009, 010,

011, 013, 015

1 3/8”

026, 031, 040, 050, 060,

070

(standard)/

1 3/8” (preheat

055, 065, 075, 090, 105,

120, 130, 140

2 1/8”

Chilled Water Coil

Four or six row chilled water cooling coils

can be factory installed. All valve controls

for cooling operation are field supplied and

field installed. Chilled water coil

connections are spun copper tube.

Table 22 - Chilled Water Coil Connection

Sizes

Model (RN-)

Coil Connection

006, 007, 008, 009, 010,

011, 013, 015

1 5/8”

075, 090, 105, 120, 130,

140

2 1/8”

Installing Contractor is responsible

for proper sealing of the water piping

entries into the unit Failure to seal the

entries may result in damage to the

Piping shall be in accordance with

national and local codes. Pressure

limiting devices, backflow preventers

and all other safety requirements are

the sole responsibility of the installing

contractor.

Loading...

Loading...