2600T Series Pressure transmitters | OI/266/FF/ADD-EN Rev. B 9

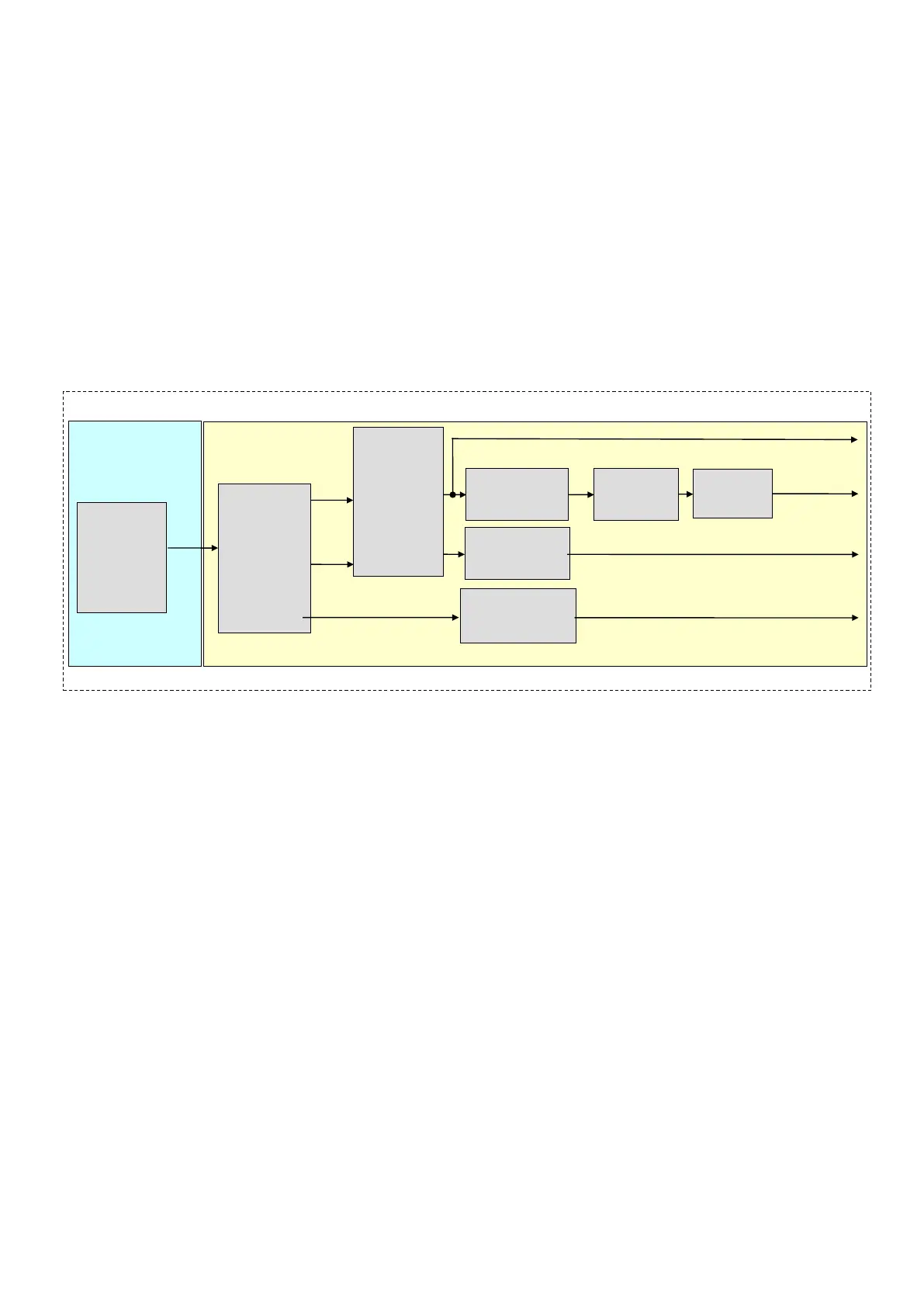

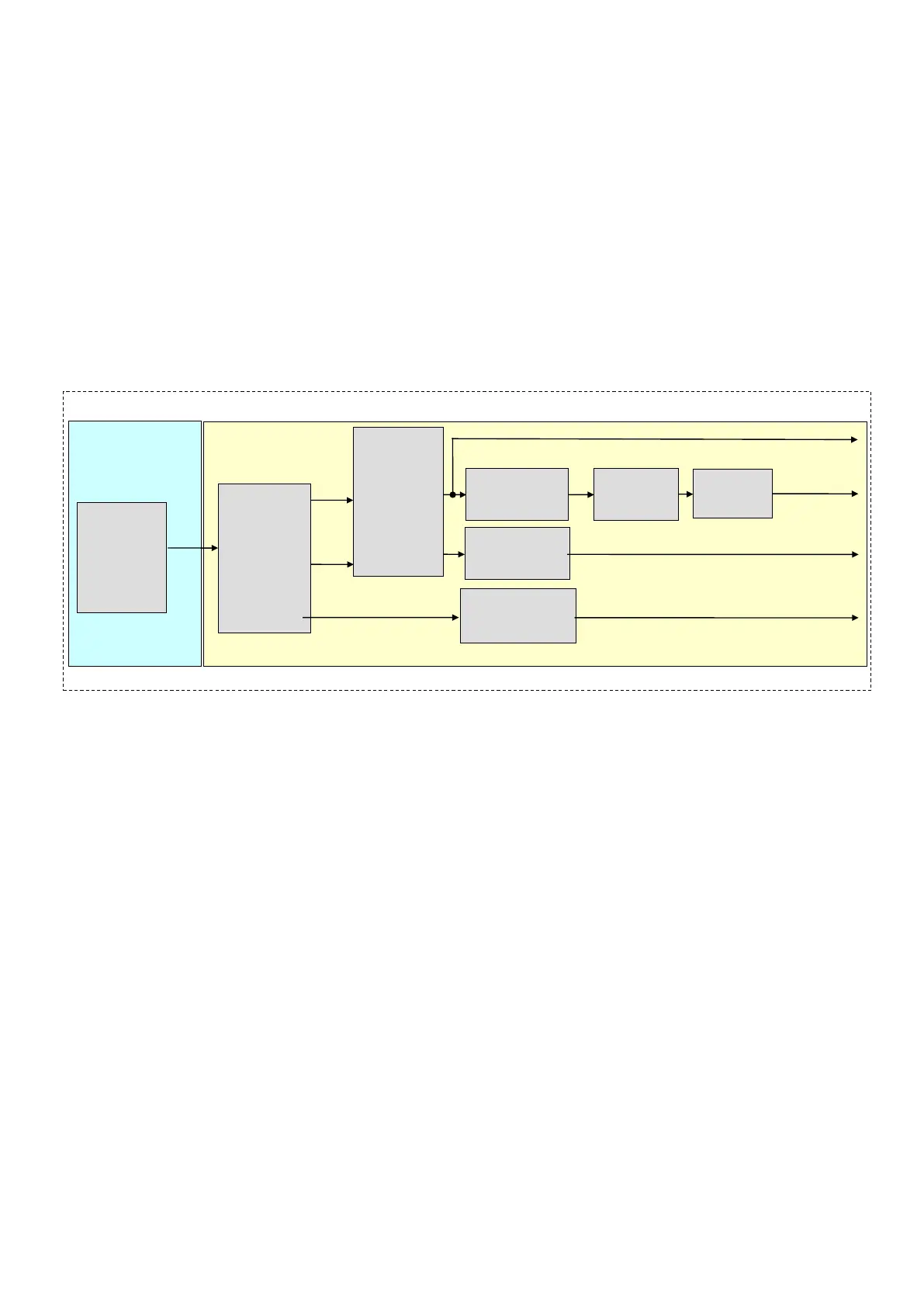

Physical I/O

SENSOR_TYPE

SENSOR_SERIAL_NUMBER

INTEGRATION_TIME

SENSOR_RANGE_100%

SENSOR_RANGE_0%

SENSOR_RANGE_UNIT

STATIC_P_

TRIM_VALUE (MV)

Static Pressure Ranging

TERTIARY_VALUE_RANGE_100%

TERTIARY_VALUE_RANGE_0%

TERTIARY_VALUE_RANGE_UNIT

PdP Output Scale

QUATERNARY_RANGE

0 – 100 %

TERTIARY_VALUE

(STATIC PRESSURE)

Calibration

/ Trimming

CAL_POINT_HI

CAL_POINT_LO

CAL_MIN_SPAN

STATIC_P_CAL_POINT_HI

STATIC_P_CAL_POINT_LO

STATIC_P_MIN_SPAN

SENSOR_TEMP_CAL_POINT

PV_Bias/ Offset

[PV = MV +/- BIAS_VALUE]

DESIRED_PRIMARY_VALUE

RESET_BIAS

BIAS_VALUE

DESIRED_STATIC_P_VALUE

RESET_STATIC_P_BIAS

STATIC_P_BIAS_VALUE

PdP Ranging

PRIMARY_VALUE_RANGE_100%

PRIMARY_VALUE_RANGE_0%

PRIMARY_VALUE_RANGE_UNIT

Transfer Function

QUATERNARY_LIN_TYPE

QUATERNARY_CUT_OFF

QUATERNARY_LIN_POINT

Sensor temp Ranging

SECONDARY_VALUE_RANGE_100%

SECONDARY_VALUE_RANGE_0%

SECONDARY_VALUE_RANGE_UNIT

SECONDARY_VALUE

(SENSOR TEMPERATURE)

PRIMARY_VALUE

(PRESSURE P-dP)

QUATERNARY_VALUE

(SCALED_PV [%])

AI _CHANNEL = 4

Pressure Transducer Block

Pressure transducer block (PRTB)

Overview

This pressure transducer block is implemented within devices whose primary process sensor has the purpose to measure pressure,

or differential pressure (P-dP). In addition, at the pressure value as primary measurement, there are other variables that can be

selected trough the Channel as input for the Analog Input blocks, these are the Sensor Temperature, the Static Pressure, for

Differential pressure sensors only, and the Scaled PV identified respectively as Secondary, Tertiary and Quaternary variables.

Block diagram

Description

The Physical I/O represents the physical interface with the process and is part of the device’s Pressure Transducer. The physical I/O

takes care to execute the basic manufacturer device specific algorithm with the purpose to convert the raw signal representing the

measured process value into a digital format. The physical I/O operations are:

– Sampling of the primary raw signal changing according the process changes.

– Validation and Elaboration of the sampled primary raw signal

– Linearization and Compensation

Result of the above operations is the RAW_VALUES produced in output of the physical I/O, see the Block Diagram, and used as

input for the Pressure Transducer Block.

The first Pressure Transducer Block operation is the Calibration/trimming of the RAW_VALUES in order to adjust its digital value to

match the real pressure measured by the Sensor block.

The RAW_VALUES after the calibration became the calibrated Measured Values (MV) represented by the PRTB_CAL_VALUE and,

for differential sensors only, PRTB_STATIC_P_TRIM_VALUE.

These Measured Values matches and represents the real inputs sampled by the sensor and any further calculation has the scope to

transform them to a Process Variables (PV).

In this perspective the first calculation applied is the elevation/suppression within the PV-Bias/Offset step executed for different rea-

sons like the correction of the mounting position or for example in any condition where part of the measure must not be considered

as part of the process.

Loading...

Loading...