2600T Series Pressure transmitters | OI/266/LowP-EN Rev.A 19

8 Operation

Important. This configuration procedure only changes the 1 … 5V

signal; it does not affect the physical process pressure (PV value)

also shown on the digital display or user interface. After performing

a correction, you must check the device configuration.

Important. Setting the lower range value by using this button is

possible if the write protection is not enabled.

8.5 Activation procedure and considerations for the

integrated LCD

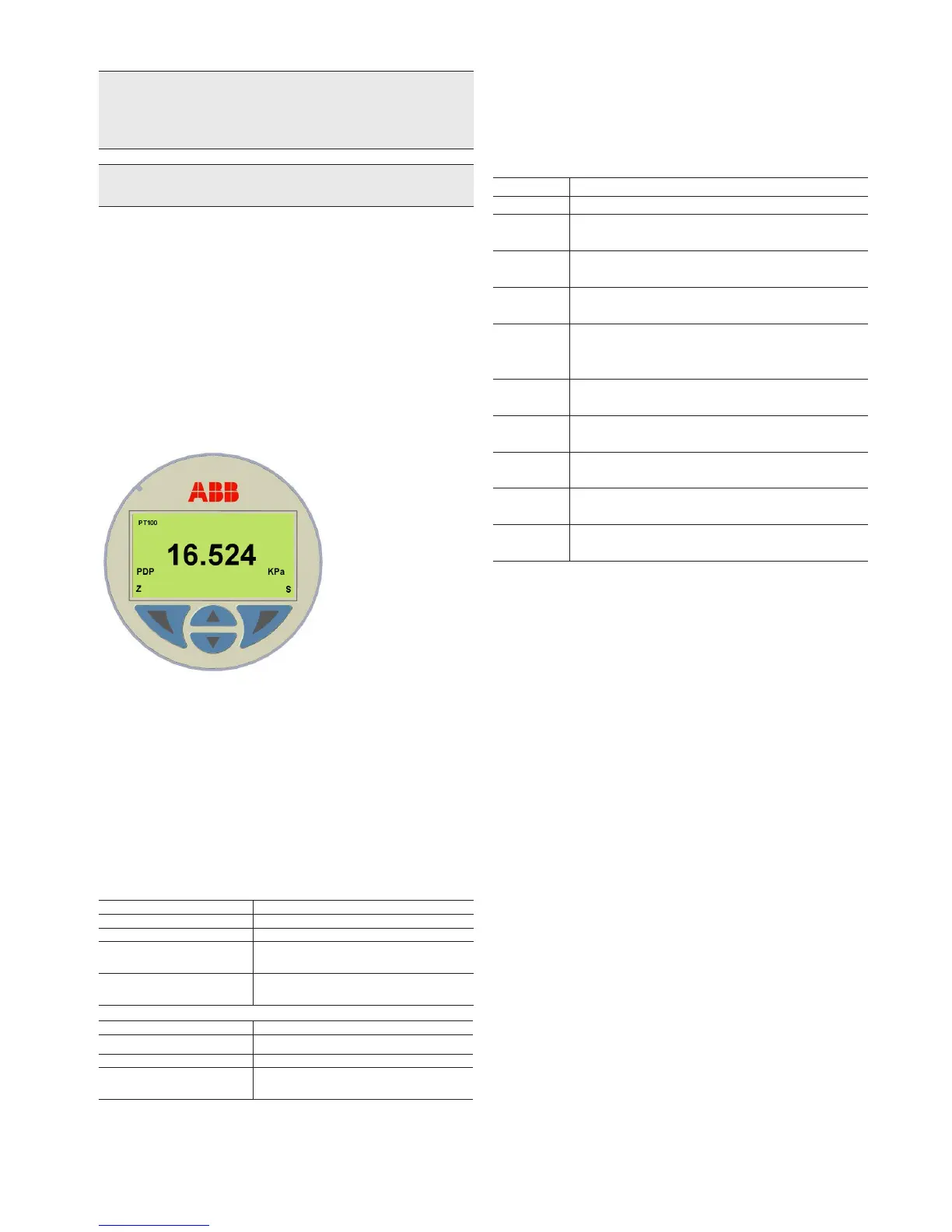

The integral LCD HMI is integrated to the 266 communication

board. It can be used to visualize the process measured

variables as well as to configure the display and the transmitter.

In addition, diagnostic information is provided. To access the

functionality of the HMI the following activation procedure

needs to be carried out:

— Keys “Z” and “S” need to be pressed simuoltaneously for

5 seconds to initiate the configurable mode.

— Press key “S” to access the menu. Key “Z” give direct

access to the diagnostics visualization.

Figure 13: Display keypad

— The menu / submenu name is displayed above in the LCD

display.

— The number / line of the currently selected menu item is

displayed in the upper right of the LCD display.

— A scroll bar is located on the right edge of the LCD

display which shows the relative position of the currently

selected menu item within the menu.

— Both of the keys can have various functions.

The meaning of these buttons is displayed below in the

LCD display above the respective button.

Button (1) functionalities Meaning

Exit Exit menu

Back Back one submenu

Cancel

Exit without saving the selected parameter

value

Next

Select next position for entering numerical

values or letters

Button (4) functionalities

Meaning

Select Select submenu/parameter

Edit Edit parameter

Ok

Save selected parameter and display

stored parameter value

8.6 HMI as feedback of the local push button

operations

As consequence of the operations described in the section 8.2,

when the Z or S buttons are released, the feedback of the

executed operation is displayed in the bottom of the LCD

(same position as per diagnostic messages):

Message Description

! Oper Done

The push button operation has been successfully executed

! Proc Too

Low

The Pressure measured in input is too low and not

acceptable for the requested operation

! Proc Too

High

The Pressure measured in input is too high and not

acceptable for the requested operation

! New URV

Error

The Zero (Z) operation cannot be accepted because the

URV would be shifted outside the Upper Sensor limit

! Span Error

The Span (S) operation cannot be accepted because the

new URV would be too close to the LRV and their

difference lower than the Minimum Span value

! Oper

Disabled

The push button operation has been refused because the

Write Protection is enabled.

! LRV Too

Low

New LRV is too low and not acceptable for the requested

operation

LRV Too

High

New LRV is too high low and not acceptable for the

requested operation

URV Too

Low

New URV is too low and not acceptable for the requested

operation

URV Too

High

New URV is too high and not acceptable for the requested

operation

8.7 HMI menu structure

Follow the instruction on the screen to perform the

configuration of the different parameters.

Integrated LCD display allows the verification and the

parameterization of the basic configuration of the 266 pressure

transmitter. The menu driven structure will guide you to the

choice of the interface language, the engineering units, the LRV

and URV (Lower range value and Upper range value), the

transfer function, the damping time and the display line 1

visualization mode (the value that need to be visualized on the

LCD).

Loading...

Loading...