2 Machine Synchronization

2.5.4. Slave robot configuration parameters

573HAC18154-1 Revision: F

© Copyright 2004-2008 ABB. All rights reserved.

2.5.4. Slave robot configuration parameters

Overview

For default configuration, see System parameters on page 74.

Use RobotStudio to change the parameters and to set up the slave robot.

Description

To make the slave robot stop and restart synchronized with the master robot:

• Set the parameter value min_sync_speed to 0.0

The slave robot will also stop if a fine point is defined in the master robot path.

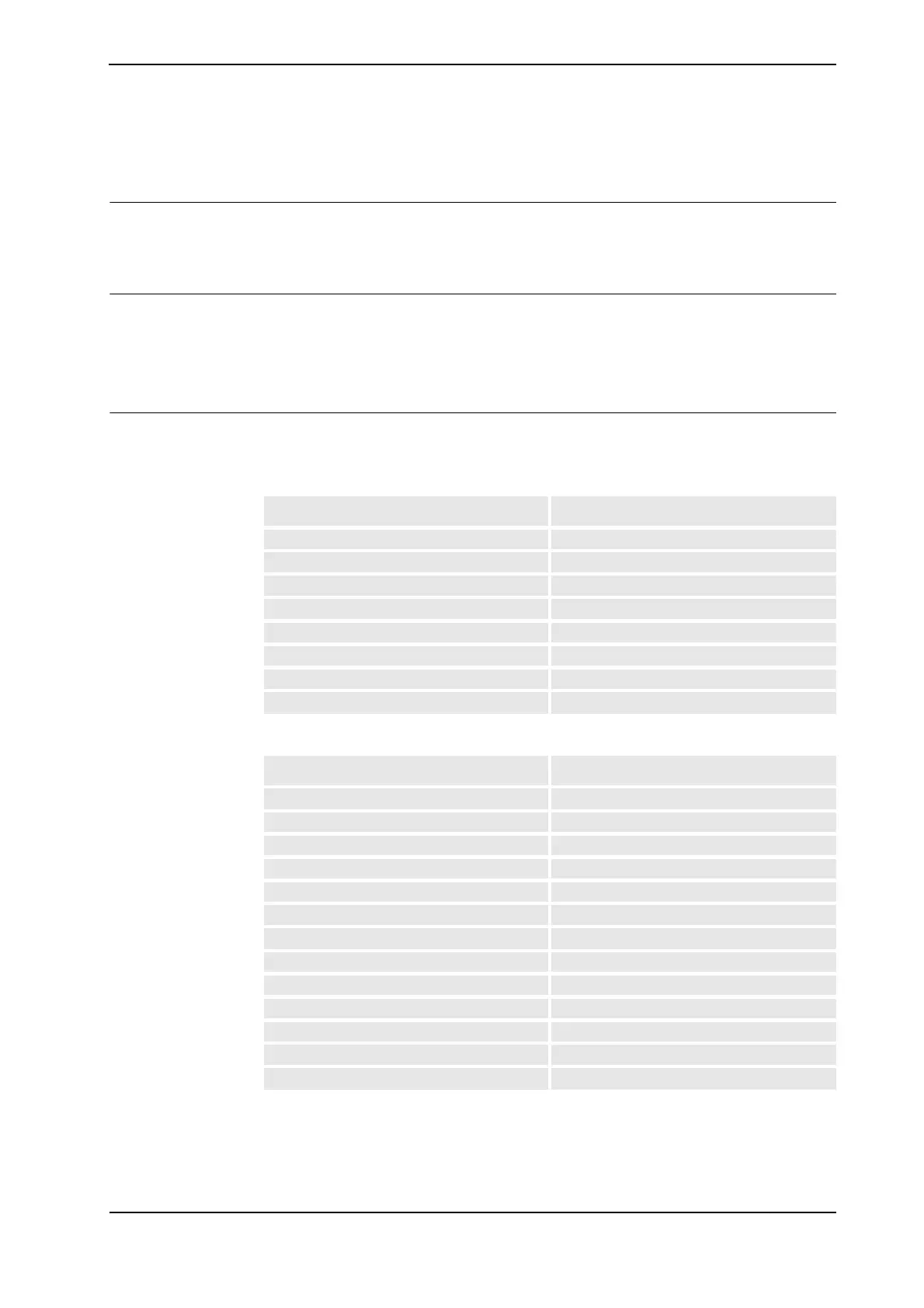

Topic: Process

SENSOR_SYSTEM

CAN_INTERFACE

SENSOR_SYSTEM/Parameter Value

Name SSYNCS1

sensor_type CAN

use_sensor CAN1

adjustment_speed 1000

min_dist 600

max_dist 20000

correction_vector_ramp_length 10

nominal_speed 1000

CAN_INTERFACE/Parameters Value

Name CAN1

Signal delay 34

Connected signal c1Connected

Position signal c1Position

Velocity signal c1Speed

Null speed signal c1NullSpeed

Data ready signal

Waitwobj signal c1WaitWObj

Dropwobj signal c1DropWobj

Data Time stamp c1DTimestamp

RemAllPObj signal c1RemAllPObj

Virtual sensor NO

Sensor Speed filter 0,33

Continues on next page

Loading...

Loading...