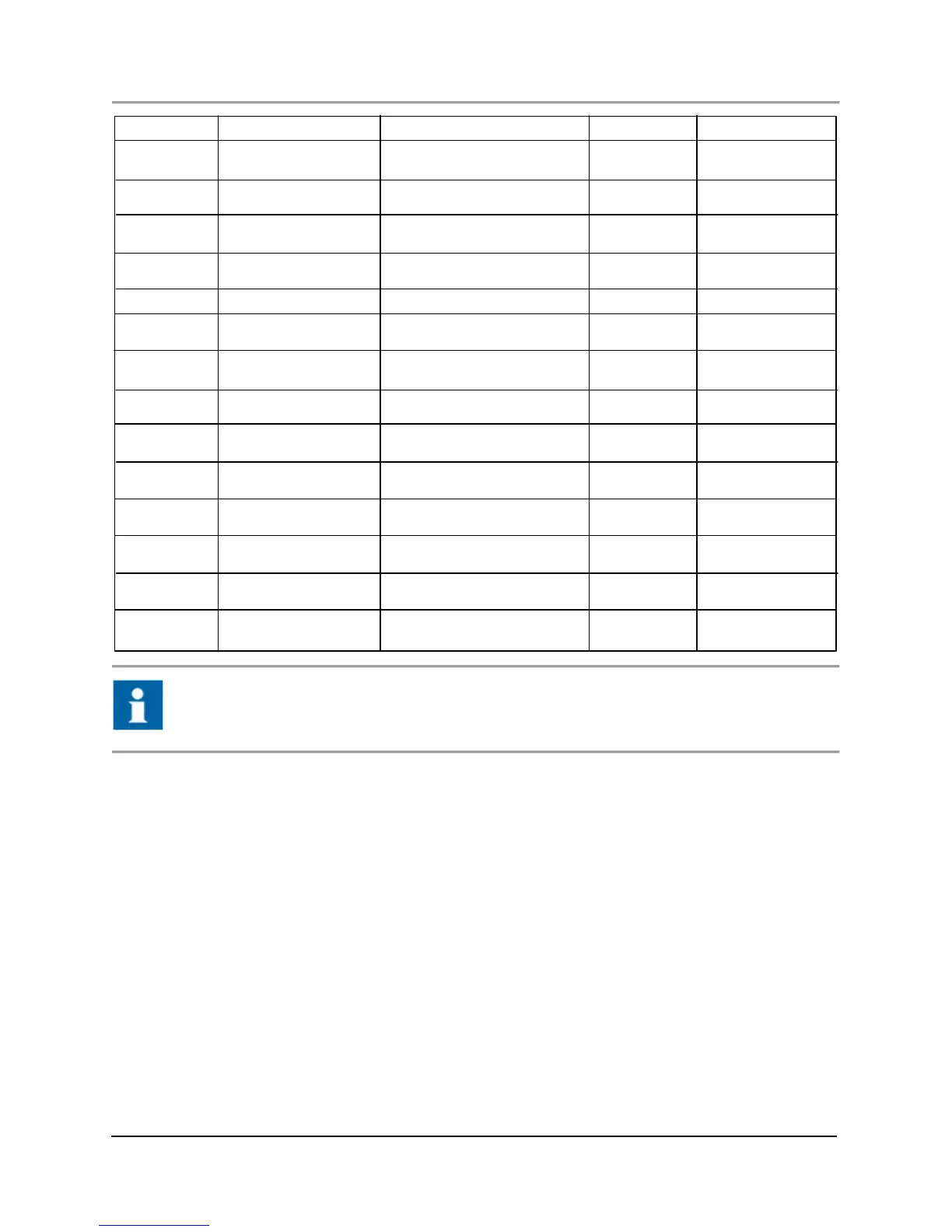

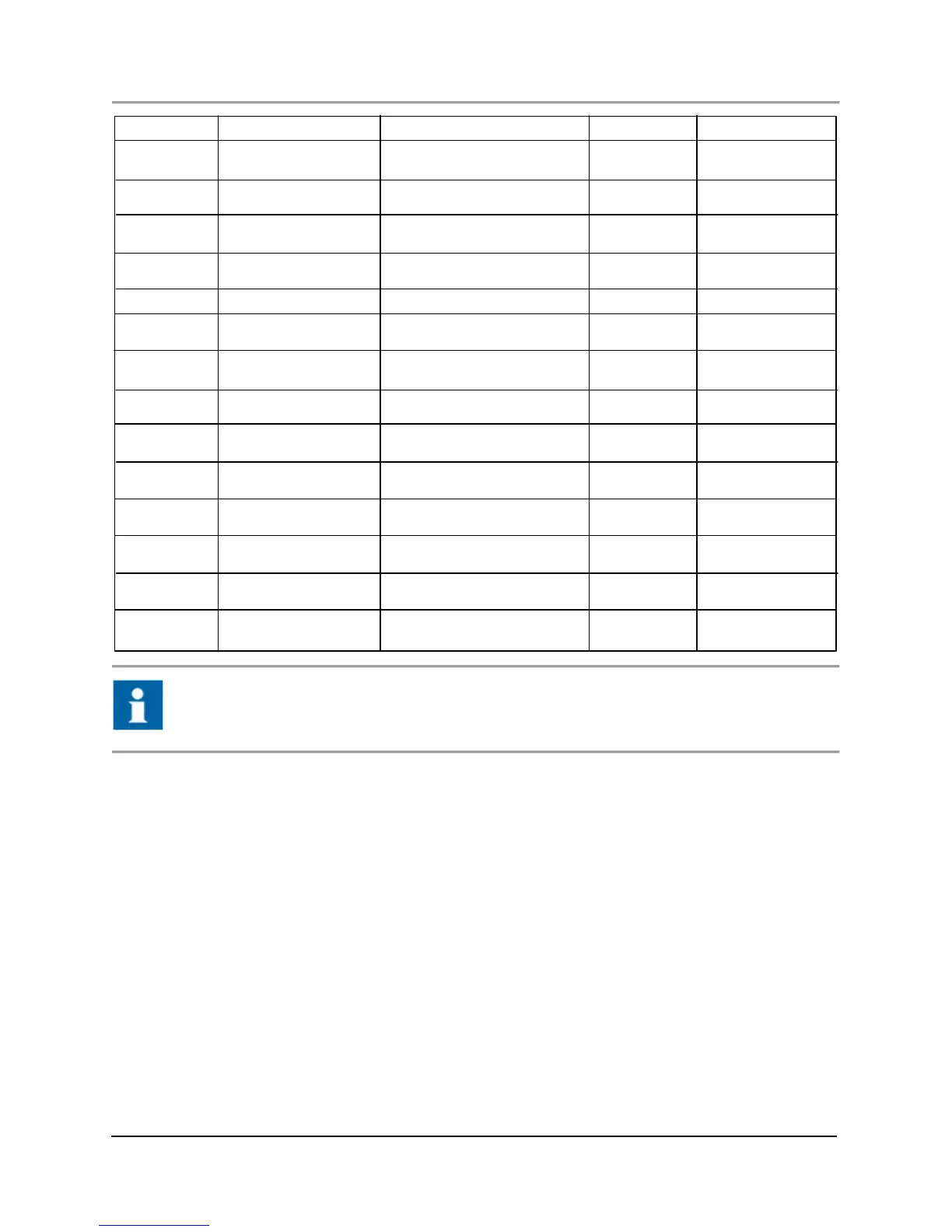

INDICATOR ISSUE RESOLUTION (CHE CK & CORRECT) RESET SOURCE

Vo l Fl ow Hi gh Volumetric Flow e xceeds Inf orma ti on Only. AOC Fast Lo op

High Limit

Vo l Fl ow Hi gh Hi gh Volumetric Flow exceeds Inf or ma ti on Only. AOC FastLoop

High High Limit

Pressure Low Low P ressure low er t han L ow Inf orma tion Only. AOC Fast Loop

Low Limit

Pressure Low P ressure lo wer t han L ow Inf orma tion Ony. AOC Fast Lo op

Limit

Pressure High Pressure exceeds High Limit Inf orma tion Only. AOC FastLoop

Pressure High High Pressure exceeds High Inf orma tion Only. AOC FastLoop

High High Limit

Te mp L ow L ow Temperature lower than Inf orma tion Only. AOC Fast Loop

Low Low Limit

Te mp L ow Temperature lower than I nf orma tion Only. AOC Fast Loop

Low Limit

Te mp High Temperature e xceeds High Inf or ma ti on Only. AOC FstLoop

Limit

Temp High High Temperature exceeds High Inf orma ti on Only. AOC Fast Lo op

High High Limit

Loo p DP Low L ow Loop Di ffe re nt ial Pre ssu re Inf orma ti on Only. AOC Fast Lo op

lower than Low Low Limit

Loop DP Low Lo op Di ffe re nt ial Pre ssure I nf orma tion Only. AOC Fast Loop

lower than Low Li mit

Loop DP High Loop Di ffe re nt ial P re ssure Inf or ma ti on Only. AOC FastLoop

exceeds High Limit

Loop DP High High Loop Di ffe re nt ial Pre ssure Inf orma ti on Only. AOC Fast Lo op

exceeds High High Limit

“#” is used in place of numbers to eliminate repeats in multiple card and oven systems. "Information

Only" signifies the set indicator is activated in response to the setup criteria. It does not necessarily

identify a fault.

5.6 Operation troubleshooting

This subsection provides troubleshooting information by category. Included in this information are symptoms, causes, and

suggestions for further fault isolation.

5.6.1 Baseline noise

The baseline (detector signal) with no sample injection appears as noise similar in appearance to “grass” on a two dimensional

drawing in the graphics display. The baseline is observed on the Manual Mode tab of the Master Controller.

Cause: Baseline or detector noise can result from contaminated carrier, makeup gas, tubing or regulators. This type of

contamination is much less pronounced with a TCD than for an FID. Other causes include defective filaments (TCD), detector

wiring, or electrical noise in the detector electronics or power supplies.

Check the background level by going to the Setup Tab>FID button and with the flame lit manually, AUTO ZERO the baseline.

(The AUTO ZERO OFFSET for an FID should be > 10 mv.)

5.6.2 Baseline or signal offset

The baseline (detector signal) is continually offset to the positive or the negative with no short term drift up or down scale.

Causes:

1. Incorrect temperatures. Inspect temperature settings and correct if necessary.

Loading...

Loading...