FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | CI/FEP630/FEH630-EN REV. D 11

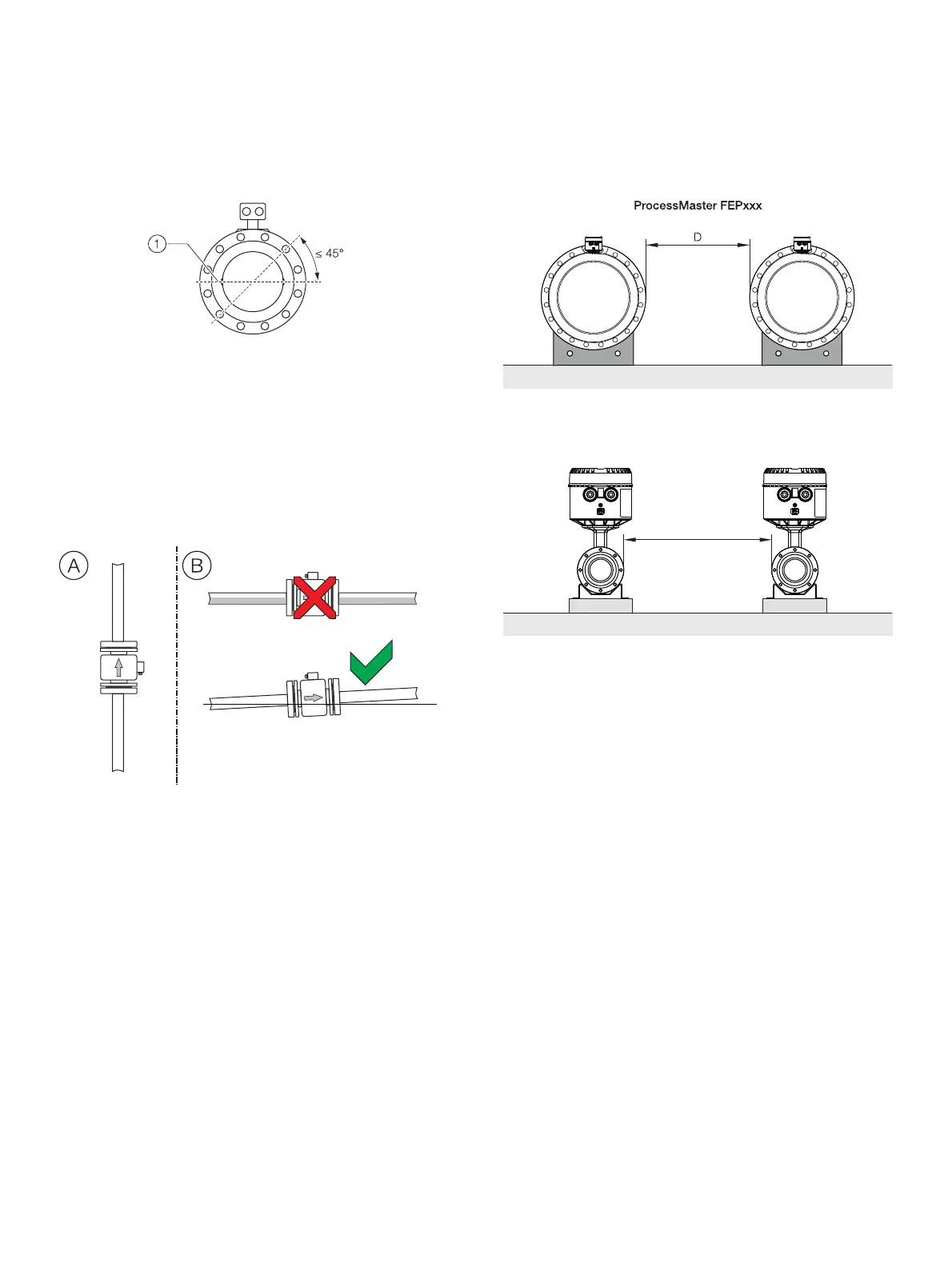

Electrode axis

1 Electrode axis

Figure 8: Orientation of the electrode axis

The flowmeter sensor should be mounted in the piping in such a

manner that the electrode axis is oriented as horizontally as

possible.

A maximum deviation of 45° from the horizontal position is

permissible.

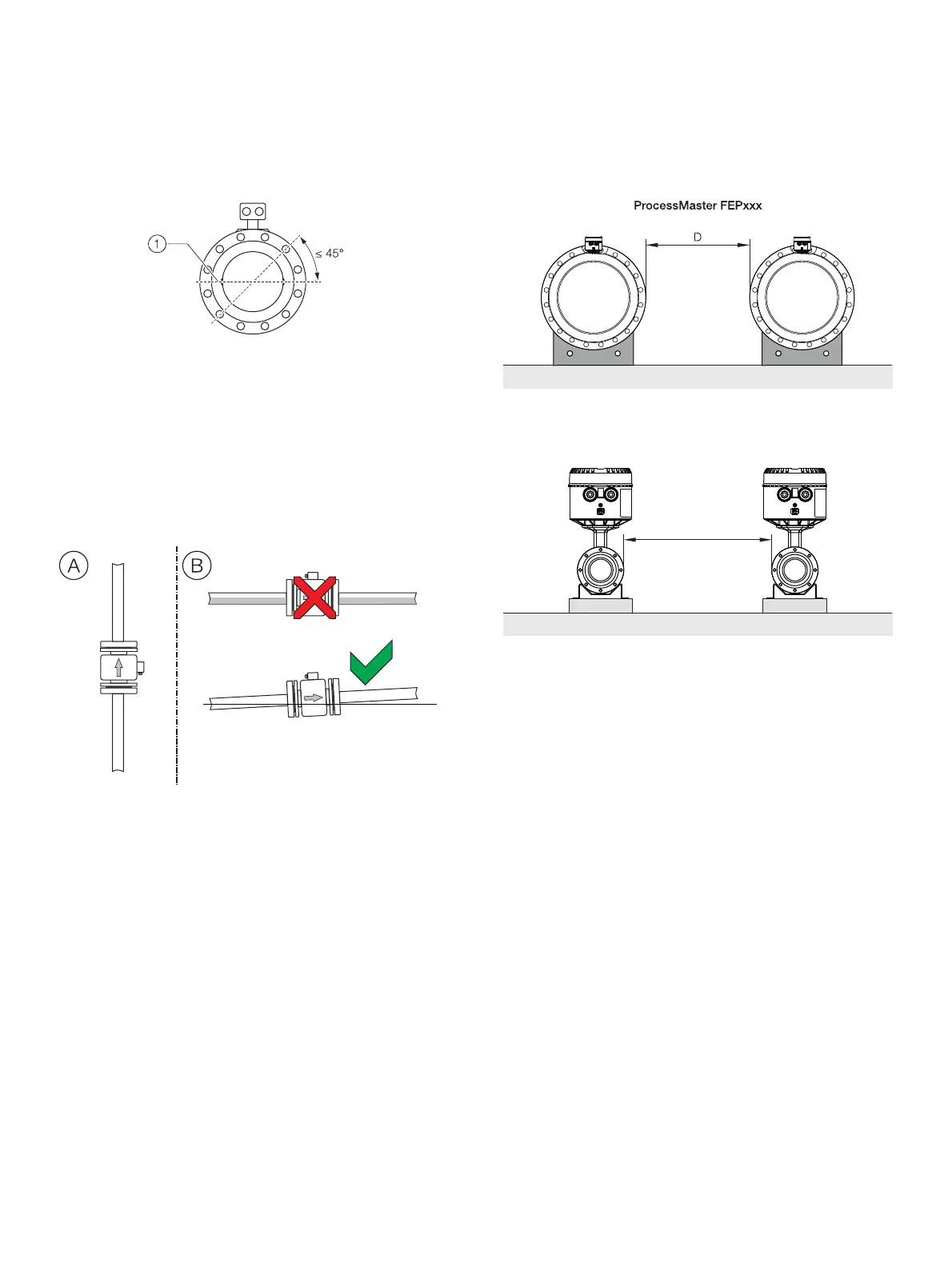

Mounting position

Figure 9: Mounting position

A Vertical installation for measuring abrasive materials,

preferably with flow in upward direction.

B For a horizontal installation, the meter tube must always be

completely filled with the measuring medium.

Provide for a slight incline of the connection for degassing.

Note

For hygienic applications, the vertical mounting position is

preferred.

For a horizontal mounting position, make sure that the sensor is

installed to be self-draining.

Minimum spacing of the devices

Spacing D: â 1.0 m (3.3 ft) for Design Level ‘A’,

â 0.7 m (2.3 ft) for Design Level ‘B’

G12063

HygienicMaster xxxFEH

D

Spacing D: â 1.0 m (â 3.3 ft)

Figure 10: Minimum spacing

• In order to prevent the devices from interfering with each

other, a minimum distance as presented in Minimum spacing

of the devices must be maintained between the devices.

• The sensor must not be operated in the vicinity of powerful

electromagnetic fields, e.g., motors, pumps, transformers,

etc. A minimum spacing of approx. 1 m (3.28 ft) must be

maintained.

• For installation on or to steel parts (e.g. steel brackets), a

minimum spacing of 100 mm (3.94 in

) must be maintained.

These values have been calculated on the basis of IEC 801-2

or IEC TC77B

Loading...

Loading...