VortexMaster FSV430, FSV450 SwirlMaster FSS430, FSS450 | CI/FSV/FSS/430/450-EN Rev. G 21

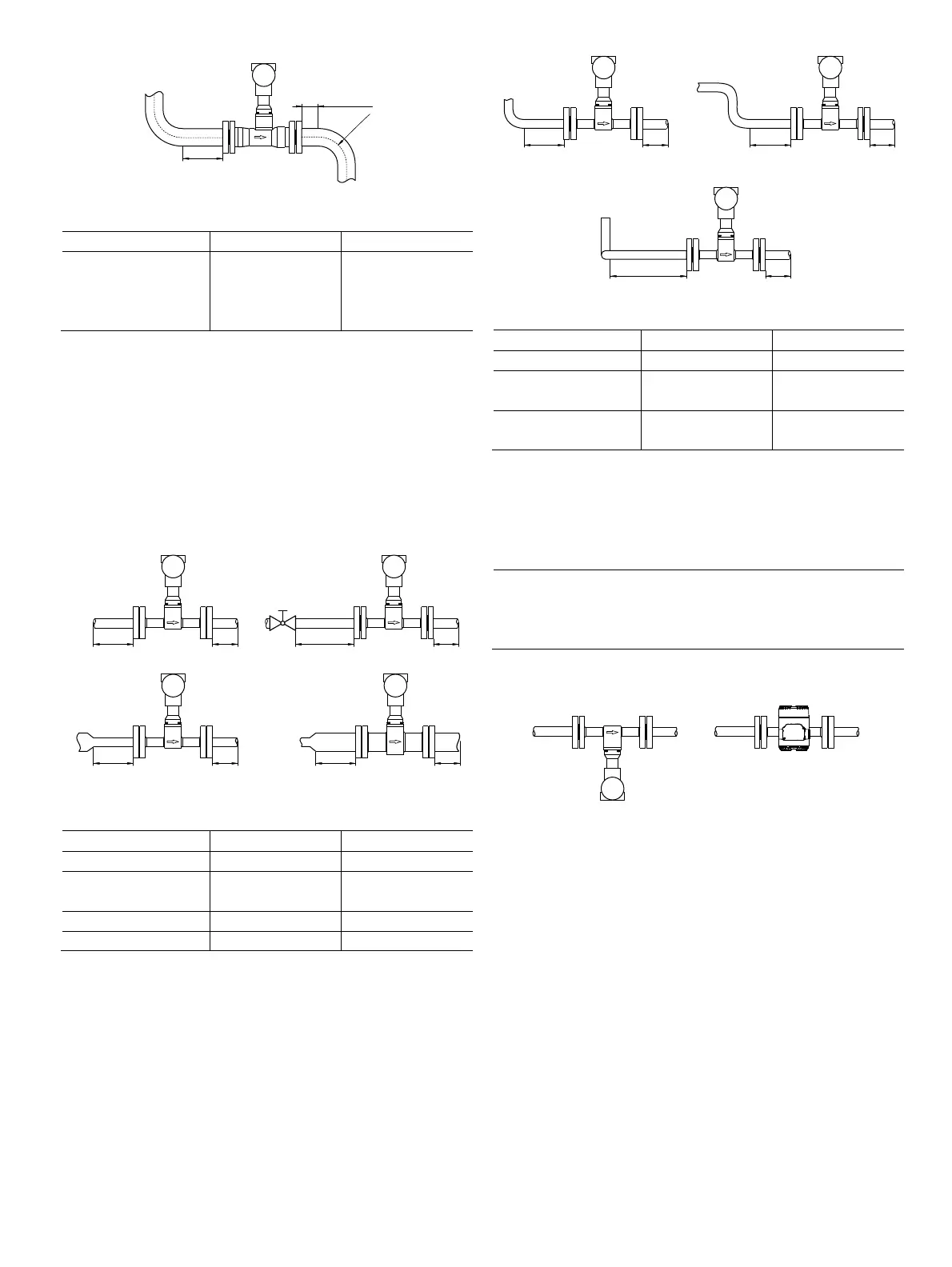

Fig. 8: Pipe sections with pipe elbows

Installation Inlet section Outlet section

Single pipe elbow

upstream or

downstream of the

meter tube

min. 3 x DN min. 1 x DN

If the elbow radius of single or double pipe elbows positioned

upstream or downstream of the device is greater than

1.8 x DN, inlet and outlet sections are not required.

VortexMaster FSV430, FSV450

In order to maximize operational reliability, the flow profile at

the inflow end must not be distorted if at all possible.

The figures below show the recommended inlet and outlet

sections for various installations.

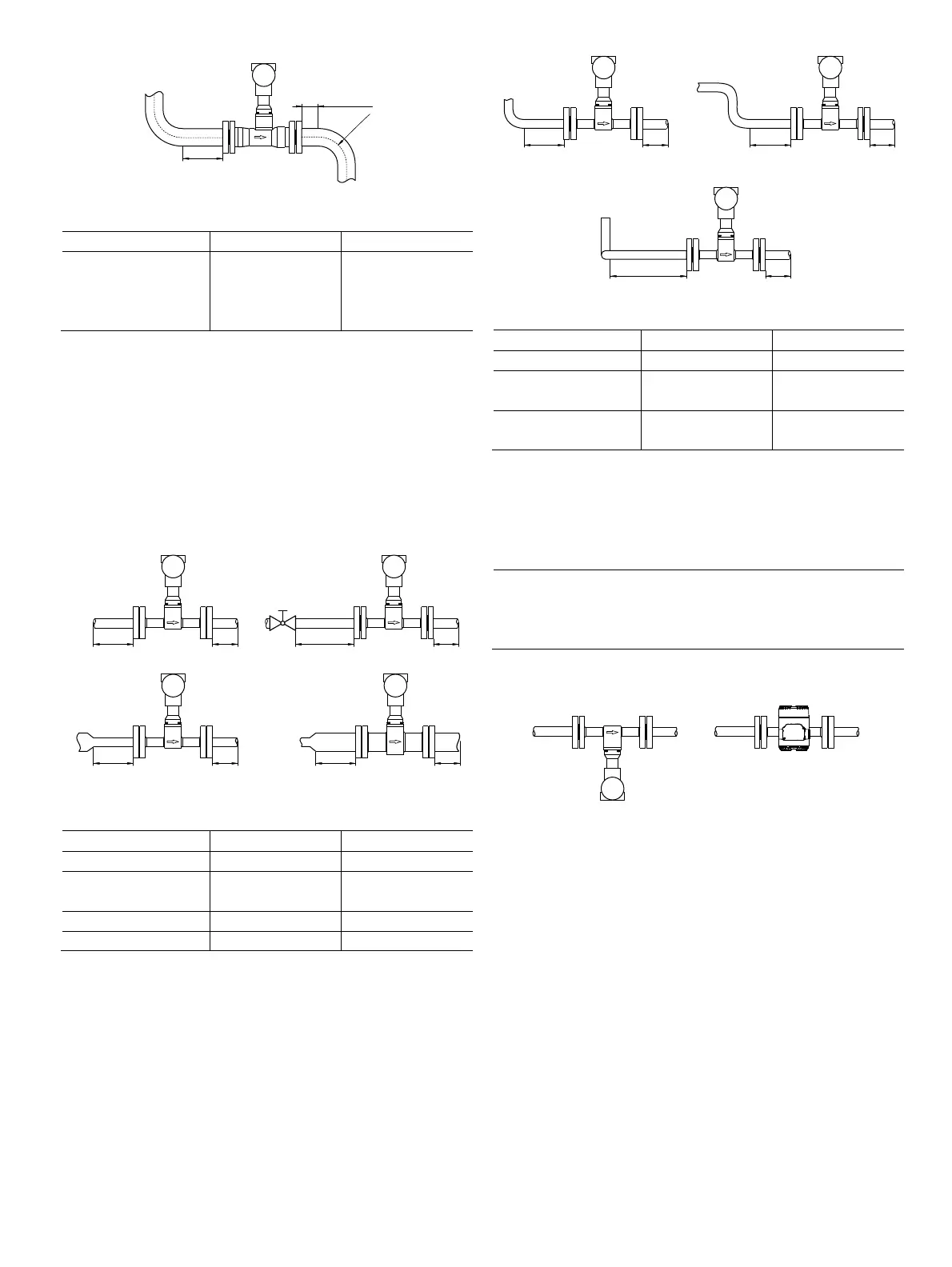

Fig. 9: Straight pipe sections

Installation Inlet section Outlet section

Straight pipe min. 15 x DN min. 5 x DN

B Valve upstream of

the meter tube

min. 50 x DN min. 5 x DN

Pipe reduction min. 15 x DN min. 5 x DN

Pipe extension min. 18 x DN min. 5 x DN

Fig. 10: Pipe sections with pipe elbows

Installation Inlet section Outlet section

Single pipe elbow min. 20 x DN min. 5 x DN

B S-shaped pipe

elbow

min. 25 x DN min. 5 x DN

C Three-dimensional

pipe elbow

min. 40 x DN min. 5 x DN

5.1.3 Avoiding cavitation

To avoid cavitation, a static overpressure is required

downstream of the flowmeter (downstream pressure). This can

be estimated using the following formula:

ppp

6,23,1

21

ρ

1

ρ

2

ρ'

Static gauge pressure downstream of the device (mbar)

Steam pressure of fluid at operating temperature (mbar)

Pressure drop, measuring medium (mbar)

5.1.4 Installation at high measuring medium temperatures

Fig. 11: Installation at high measuring medium temperatures

At high measuring medium temperatures > 150 °C (> 302 °F),

the sensor must be installed so that the transmitter is pointing

to the side or downward.

G11752

≥3 x DN

≥1 x DN

≥1,8 x DN

G11751

≥15 x DN ≥ 5 x DN ≥50 x DN ≥ 5 x DN

≥15 x DN ≥ 5 x DN ≥18 x DN ≥ 5 x DN

A

B

CD

G11752

≥ 20 x DN ≥ 5 x DN

A

B

≥ 25 x DN ≥ 5 x DN

C

≥ 40 x DN ≥ 5 x DN

G11755

Loading...

Loading...