26 CI/FSV/FSS/430/450-EN Rev. G | VortexMaster FSV430, FSV450 SwirlMaster FSS430, FSS450

5.3.2 FSS430, FSS450

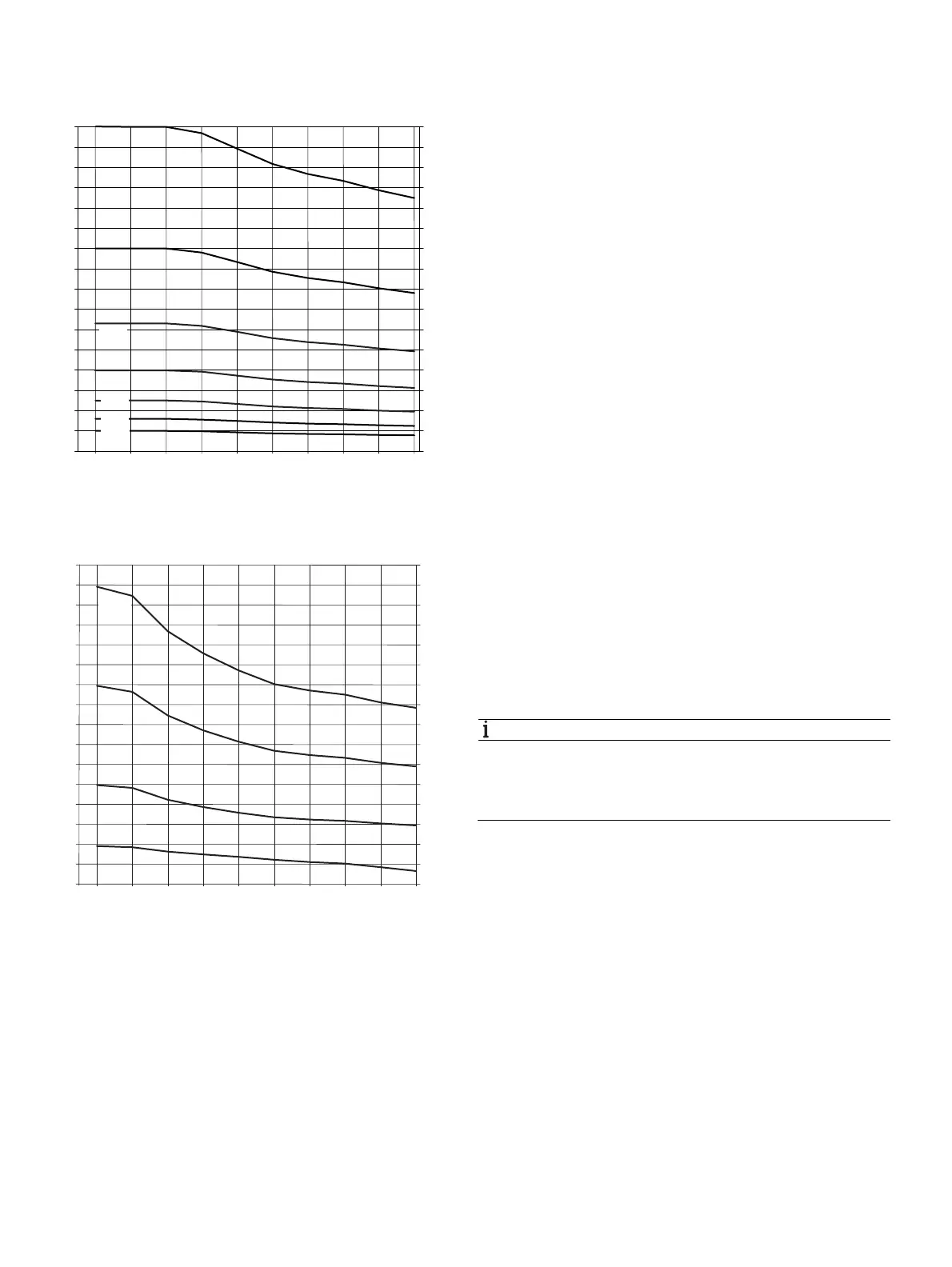

G11789

TS [°C /°F]

20 50 100 150 200 250 280 300 350 400 [°C]

160

140

120

100

80

60

40

20

0

PN 10

PN 16

PN 25

PN 40

PN 63

PN 100

PN 160

2320

2030

1740

1450

1160

870

580

290

0

68 122 212 302 392 482 536 572 662 752 [°F]

PS [psi]PS [bar]

Fig. 22: DIN flange process connection

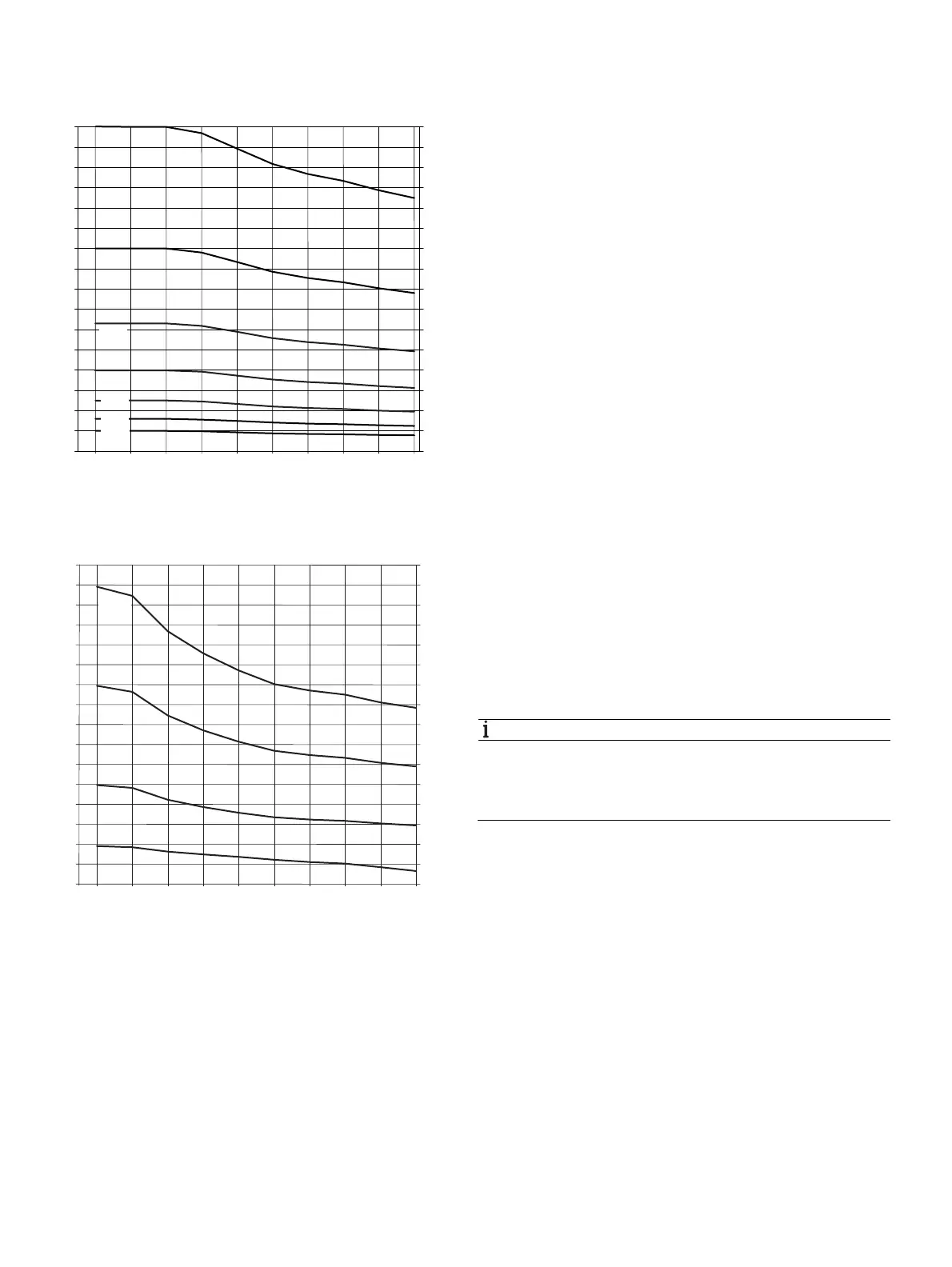

G11790

TS [°C / °F]

20 50 100 150 200 250 280 300 350 400 [°C]

PS [bar]

160

140

120

100

80

60

40

20

0

CL 900

CL 600

CL 300

CL 150

2320

2030

1740

1450

1160

870

580

290

0

68 122 212 302 392 482 536 572 662 752 [°F]

PS [psi]

Fig. 23: ASME flange process connection

5.4 Installing the sensor

Observe the following points during installation:

— For devices with a remote mount design, ensure that the

sensor and transmitter are assigned correctly.

— The flow direction must correspond to the marking, if

present

— The maximum torque for all flanged connections must be

observed

— The devices must be installed without mechanical tension

(torsion, bending).

— Wafer type devices with coplanar counter flanges should

be installed with suitable gaskets only.

— Use gaskets made from a material that is compatible with

the measuring medium and measuring medium

temperature may be used

— The piping may not exert any inadmissible forces or

torques on the device

— Do not remove the sealing plugs in the cable glands until

you are ready to install the electrical leads

— Make sure the gaskets for the housing cover are seated

correctly Carefully seal the cover. Tighten the cover fittings

— Do not expose the transmitter to direct sunlight and

provide for appropriate sun protection where necessary

— When selecting the installation site, make sure that

moisture cannot penetrate into the terminal box or the

transmitter housing

The device can be installed at any location in a pipeline under

consideration of the installation conditions.

1. Position the meter tube coplanar and centered between

the piping.

2. Install gaskets between the sealing surfaces.

NOTICE

For achieve the best results, ensure the gaskets fit

concentrically with the meter tube

To ensure that the flow profile is not distorted, the gaskets

must not protrude into the piping.

Loading...

Loading...