4-1

Questions? Refer to Page 10-10 for Technical Support Instructions.

This chapter describes the steps for running a control test with control solutions. Control tests verify the performance of

the Precision Xceed Pro Monitor and Test Strips.

The quality control features of the monitor can be customized to fit the requirements of each facility.

The monitor can be set to require:

• Testsoflow,normalandhighcontrolsolutionsoravariationdependingonthefacility’spolicy.

• Testsofcontrolsolutionsatrelativetimes(e.g.every24hours)orfixedtimes(e.g.at6:00a.m.,2:00p.m.,and

10:00 p.m.).

• ControltestresultstoappearasnumericvalueorPass/Fail.

These quality control features can be set through the data management system.

Operating Guidelines for Control Solution Testing

Observe the following guidelines to obtain optimal quality control results using the Precision Xceed Pro System:

• UseonlycontrolsolutionsapprovedforusewithPrecisionXceedProandPrecisionPCxPlusTestStripstoverify

the performance of the Precision Xceed Pro Monitor and Test Strips.

• Whenopeninganewbottle,writethediscarddateonthebottlelabel.Eachbottleofcontrolsolutionisstablefor

90 days after opening or until the expiry date printed on the label, whichever comes first.

• Donotusecontrolsolutionsaftertheexpirydateprintedonthebottlesandthebox.Afterthebottlehasbeen

opened, do not use after the discard date written on the bottle.

• Invertthecontrolsolutionbottleseveraltimestoensurethoroughmixingbeforeuse.

• Invertandtapthecappedcontrolsolutionbottletoremoveairbubblesfromthetipofthebottle.

• Wipethecontrolsolutionnozzlewithacleangauzeortissuebeforeandaftereachtest.

• Donotscanoneteststripfoilpacket’sbarcodeanduseateststripfromanotherfoilpacket.Thismaycause

incorrect results to be generated.

• Replacethecorrectcaponthebottleandtightenthecapimmediatelyaftereachuse.

When To Test with Control Solutions

• Asrequiredbyyourfacility’squalitypolicyorlocalregulatoryrequirements.

• ToverifytheperformanceofthePrecisionXceedProSystem.

Workflow

The monitor expects to run control tests in the following order. If a control level is disabled, the monitor will expect

to skip it. If β-ketone testing is disabled, the operator will not receive a prompt to perform this test.

1. Low Glucose

2. Mid Glucose

3. High Glucose

4. Low Ketone

5. Mid Ketone

6. High Ketone

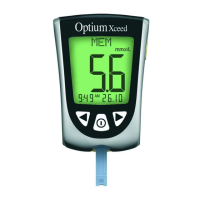

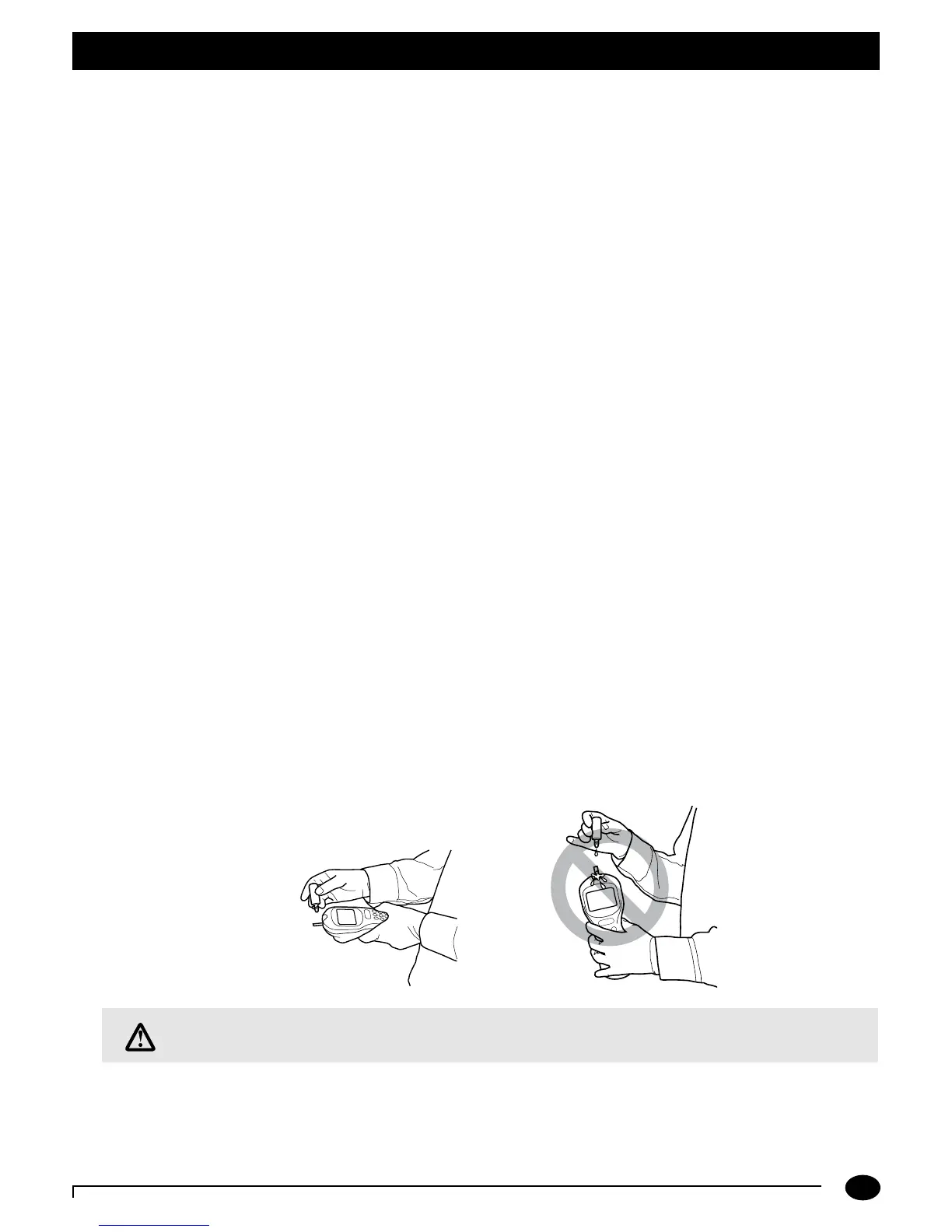

IMPORTANT: Do not allow control solution to drip down into monitor port.

Control Test

Chapter 4 : Control Test

Loading...

Loading...