115 ADAM-6200 User Manual

Chapter 4 System Configuration

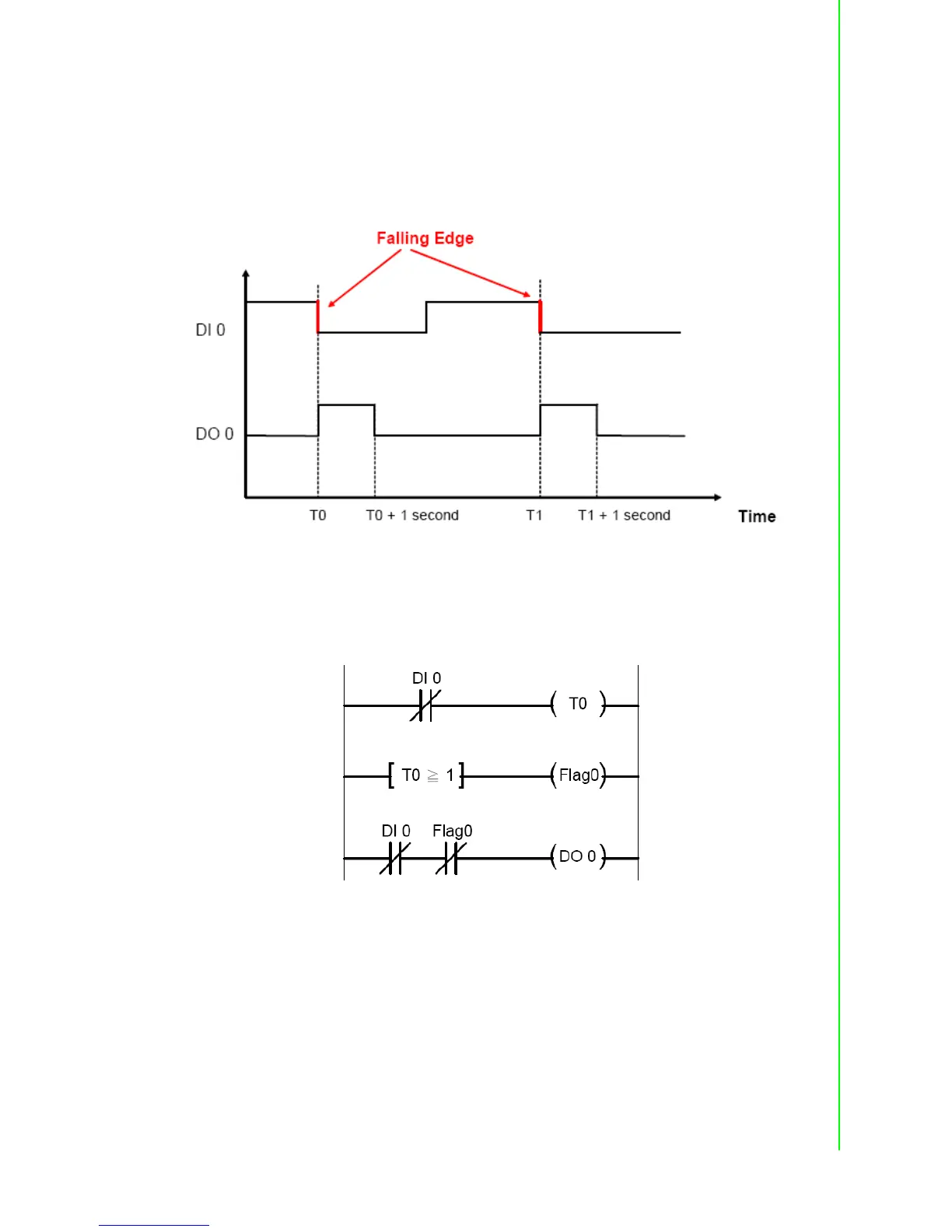

7. Falling Edge

For Falling Edge application, the DO value will be activated to logic high, when DI

value is changing from logic high to logic low (it is so-called falling edge). But the DO

value won't continuously remain logic high. Instead, after a specific period (in the

example project, it is 1 second), the DO value will back to logic low. The time chart is

shown as below:

You can see the DO 0 will only be triggered when falling edge of DI 0 occurs. In the

example project we provide, the DO status will remain logic high for 1 second. Then it

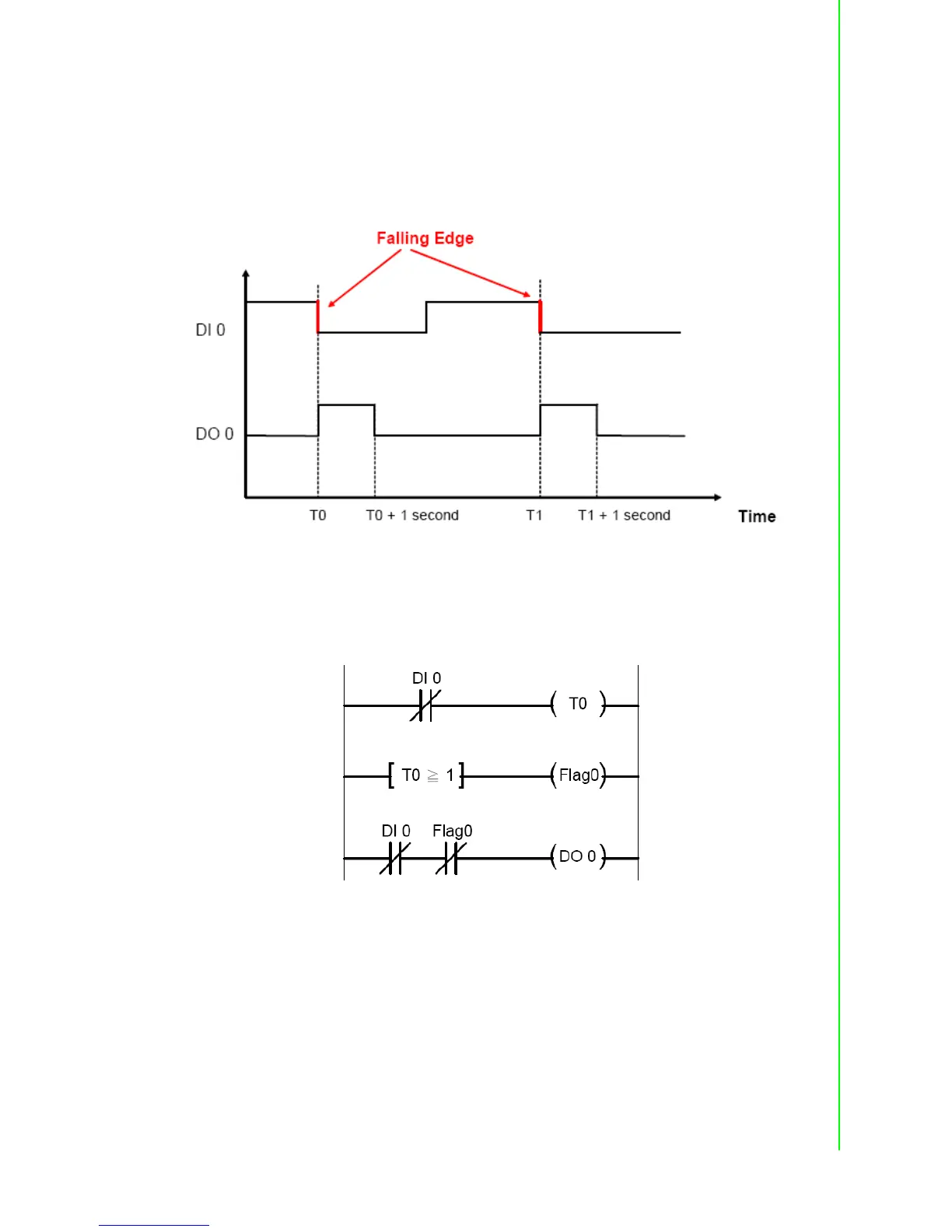

will back to logic low. When PLC is used for this kind of application, the ladder dia-

gram will be likely as below:

Loading...

Loading...