12

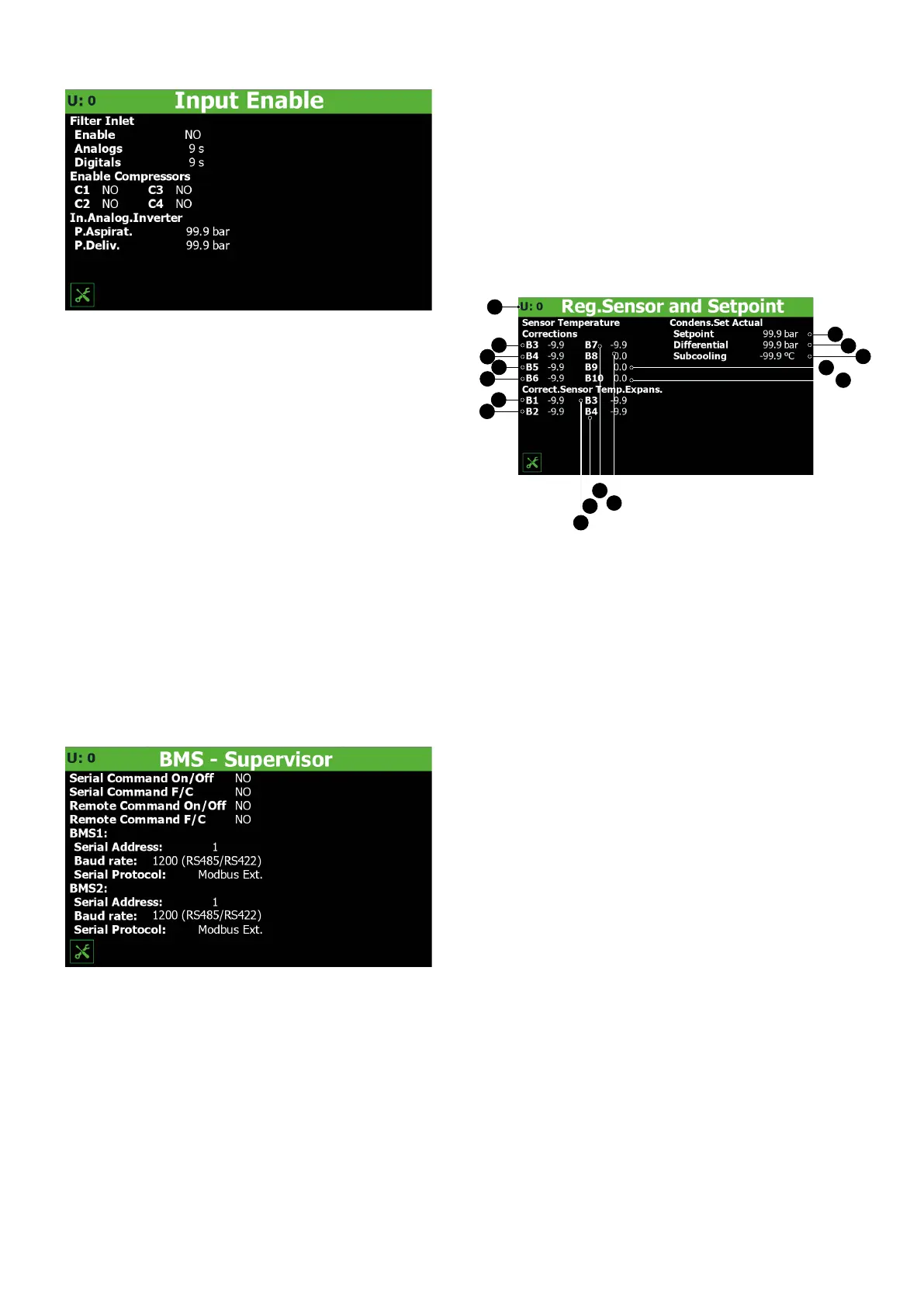

7.3 ENABLES INPUT FILTERS AND COMPRESSORS

— Indicates to which compressor the displayed data refers (U:1 = Master; U:2 =

Slave 1; U:3 = Slave 2; U:4 = Slave 3)

— indicates the actual setting relating to the enabling of the delay to read the an-

alogue and digital inputs of the pCO5 board (YES = lters enabled; NO = lters

not enabled)

— Indicates the value assigned to the delay in reading the analogue inputs of the

pCO5 board

— Indicates the value assigned to the delay in reading the digital inputs of the

pCO5 board

— Indicates the actual setting relating to the enabling (only from the master win-

dow U:1) of compressor 1 (YES= compressor enabled; NO = compressor not

enabled)

— Indicates the actual setting relating to the enabling (only from the master win-

dow U:1) of compressor 2 (YES= compressor enabled; NO = compressor not

enabled)

— Indicates the actual setting relating to the enabling (only from the master win-

dow U:1) of compressor 3 (YES= compressor enabled; NO = compressor not

enabled)

— Indicates the actual setting relating to the enabling (only from the master win-

dow U:1) of compressor 4 (YES= compressor enabled; NO = compressor not

enabled)

— Indicates the actual pressure value read at compressor intake

— Indicates the actual pressure value read at compressor ow

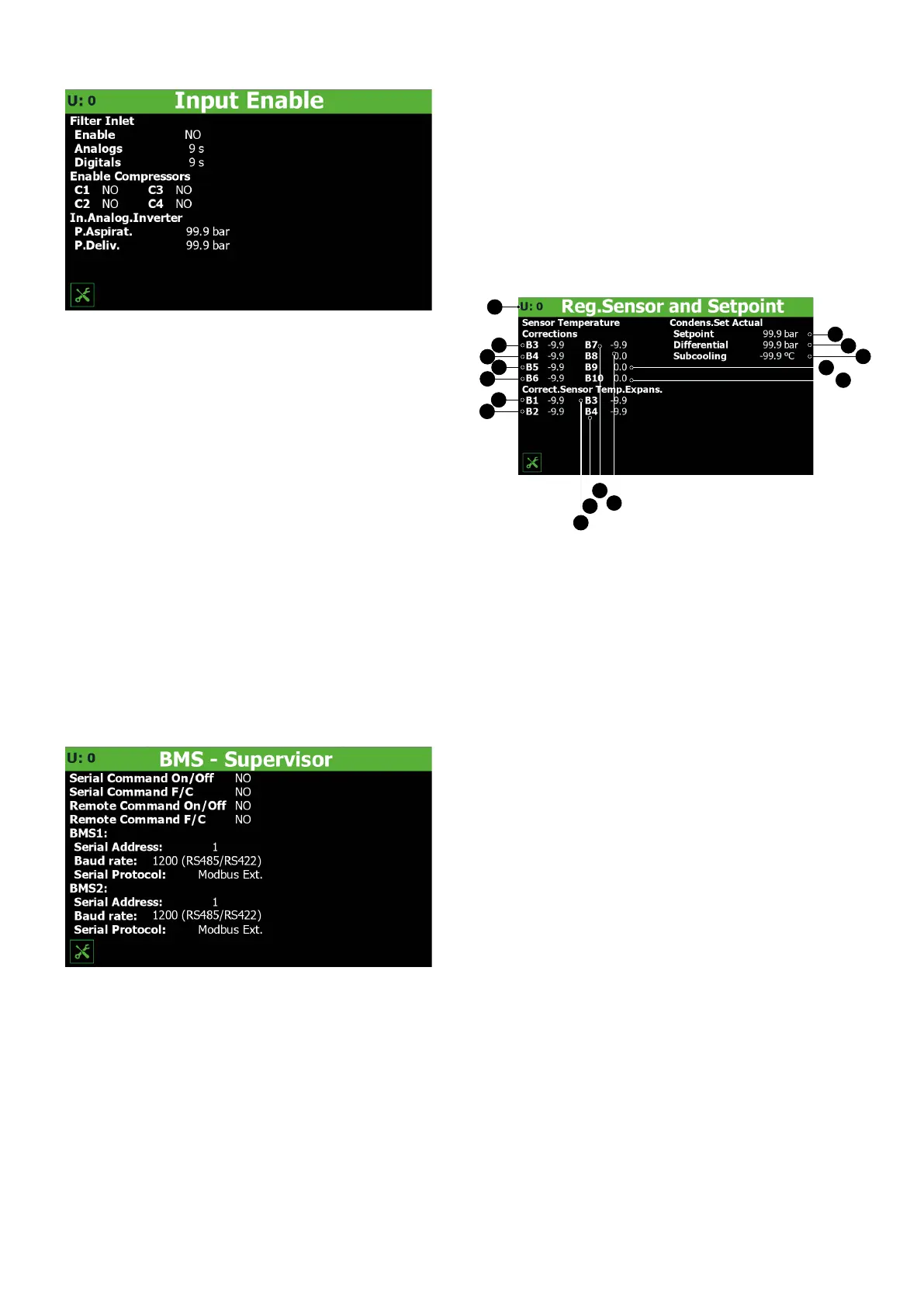

7.4 ENABLING AND SETTING CONTROL VIA THE REMOTE

SUPERVISOR BMS

— Indicates to which compressor the displayed data refers (U:1 = Master; U:2 =

Slave 1; U:3 = Slave 2; U:4 = Slave 3)

— Indicates the current setting for ON/OFF via the supervisor (YES = function ena-

bled; NO = function disabled)

— Indicates, only on heat pumps, the actual setting for the changeover from su-

pervisor (YES= function enabled; NO = function disabled)

— Indicates the actual setting for the ON/OFF from digital input ID1 (YES= func-

tion enabled; NO = function disabled)

— Indicates, only on heat pumps, the actual setting for the changeover from digi-

tal input ID2 (YES= function enabled; NO = function disabled)

— Indicates the current address assigned to the unit for communicating with the

remote supervisor BMS1

— Indicates the actual value assigned to the communication speed between the

unit and the BMS1 supervision system; the values that can be set are: 1200 or

19200 Baud

— It can indicate (if the appropriate accessory serial interface board is provided

and properly installed) the actual protocol selected for communication be-

tween unit and BMS; the protocols available are:

Modbus RTU Slave = RS485 modbus supervisor;

CarelRS485 = communication protocol to pilot the expansion boards;

Bacnet = bacnet supervisor;

Lonworks = communication protocol to pilot the Lon expansion boards;

— Indicates the current address assigned to the unit for communicating with the

remote supervisor BMS2

— Indicates the actual value assigned to the communication speed between the

unit and the BMS2 supervision system; the values that can be set are: 1200 or

19200 Baud

— Display only parameter, indicates the communication protocol for the Slave

compressors

7.5 OFFSET CONFIGURATION ON ANALOGUE INPUTS

1

2

3

4

5

10

11

6

7

9

8

12

13

14

15

16

1. Indicates to which compressor the displayed data refers (U:1 = Master; U:2 =

Slave 1; U:3 = Slave 2; U:4 = Slave 3)

2. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the inlet water probe (if displaying the U:1

master page) or the evaporator water outlet (if displaying the Slave U:2, 3, 4

pages)

3. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the probe placed at compressor ow

4. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the evaporator outlet probe

5. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the amperometric transformer

6. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the multi-function input (if displaying the

U:1 master page) or the recovery outlet (if displaying the Slave U:2, 3, 4 pages)

7. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the outside air probe

8. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the temperature probe on the evaporator

gas side (only for units with recovery or freecooling)

9. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the liquid temperature probe (only for units

with recovery or freecooling)

10. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the recovery inlet water probe (for version

with recovery) or freecooling coil input (for freecooling units)

11. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the recovery outlet water probe (for version

with recovery) or freecooling coil output (for freecooling units)

12. Indicates the actual value to be added (or subtracted in case of negative val-

ues) as oset to the value read by the probe placed at intermediate heat ex-

changer input (freecooling versions)

13. Not used

14. Indicates the actual set value for adjusting the condensation pressure calculat-

ed according to the outside temperature

15. Indicates the dierential applied to the actual set for adjusting the condensa-

tion pressure

16. Indicates the actual set for subcooling

Loading...

Loading...