6. DESCRIPTION

OF COMPONENTS

6.1. STRUCTURE

Base and support structure

Made up from hot galvanised sheet steel

elements with suitable thickness. All parts

painted with polyester powder paints (RAL

9002), resistant to atmospheric agents.

Realised in a way to allow total accessibility

to the components

internal components. All panels are

covered with sound-absorbent material

with suitable thickness.

6.2. COOLING CIRCUIT

Compressor

High efficiency scroll hermetic compressors

(mounted on anti-vibration supports),

activated by a 2-pole electric motor with

internal heat protection.

Evaporator

Plate type (AISI 316). It is insulated externally

with closed cell material to reduce thermal

dispersions.

Condenser

Plate type (AISI 316). It is insulated externally

with closed cell material to reduce thermal

dispersions.

Dehydrator filter,

Hermetic-mechanical with cartridges made

of ceramic and hygroscopic material, able

to withhold impurities and any traces of

humidity present in the cooling circuit.

Biflow type up to model 080.

Indicator for liquid passage with

humidity presence signal,

Used to check the refrigerant gas load and

the eventual presence of humidity in the

cooling circuit.

Electronic thermostatic valve

(STANDARD FOR ALL MODELS).

The valve modulates the flow of gas to the

evaporator, according to the heat load, in

order to ensure a correct heating level of

the intake gas.

One-way valves

(FOR MODELS 100-140-160).

Allows the passage of the refrigerant

in just one direction.

4-way cycle reverse valve

Inverts the flow of refrigerant gas.

6.3. MAIN OPERATIONS

The WRL-H heat pumps are supplied as per

standard with:

• Water filter; Equipped with steel

filtering mesh; prevents the heat

exchangers from clogging.

• Differential pressure switch; It checks

that here is water circulation inside the

heat exchangers. Adversary, it blocks

the unit

• Safety valve (6 bar).

Equipped with a piped discharger

and intervenes by discharges the

over pressure in case of anomalous

pressures.

• Expansion tank (for version with

storage tank/storage tank+pumps)

With nitrogen pre-load membrane.

• Air vent

• Drain cock

• Cut-off cock

Below find the description of the hydraulic

components, present in the various other

versions. WRLH°TBPQ.

6.4. WATER FEATURES

6.5. COMPONENTS THAT CAN BE

CONFIGURED

The components that can be selected by

the configurator are:

• 3-speed ON/OFF pump (up to 080

model) or standard three-phase one-

speed pump for 100-140-160 models.

• Larger single speed three phase pump

(100-140-160 models).

• Pump with phase cut set-up (up to 080

model).

• Inverter pump (up to 080 model).

• Storage tank; “100 litres WRL 025-080”,

“150 litres WRL 100-160”.

The following is available for well/sheet

water applications:

• 2-way modulating valve (0÷10 V

signal). Maximum differential pressure

4bar/40kPa.

ATTENTION:

In case of power failure

the valve remains locked

in the working position. In

order to avoid unnecessary

water consumption, it is

recommended to install,

upstream of the water mains

supply, a shut-off device

6.6. DHW SIDE HYDRAULIC

COMPONENTS

• Water filter; Equipped with steel

filtering mesh; prevents the heat

exchangers from clogging.

• TOTAL RECOVERY (OPTIONAL)

Plates type (AISI 316), it is insulated

externally with closed cell material to

reduce heat loss.

In the event of installation

(pump/external total

recovery) for correct

functioning of the machine it is

mandatory that it is managed

by the regulation of the same.

6.7. SAFETY AND CONTROL

Low pressure transducers

Placed on the low pressure side of the

cooling circuit, it signals the work pressure

to the control board, generating a pre-

warning in case of anomalous pressures.

High pressure transducer

Placed on high pressure side of cooling

circuit, signals the work pressure to control

board, generating a pre-warning in case

abnormal pressure occurs.

High pressure pressure switch

With fixed calibration, placed on high

pressure side of cooling circuit, inhibits

functioning of compressor if abnormal work

pressure occurs.

Watertemperature probe (DHW);

The unit is delivered supplied with n° 1

temperature probe for any DHW tank.

6.8. ELECTRIC CONTROL BOARD

AND REGULATION

Electric power and control board,

manufactured in compliance with the EN

60204-1/IEC 204-1 Standards, complete

with:

• door lock main isolating switch,

• magnet circuit breaker switches and

contactors for compressors,

• phase sequence control,

• clamps for signalling the remote alarm,

• clamps for signalling compressor

switch-on status,

• clamps for differential pressure switch

alarm signal,

• clamps for external air temperature

probe (ACCESSORY),

• soft-start (OPTIONAL),

• control circuit numbered cables,

• clamps for 3-way valve,

• 0-10V clamps for modulating valve

control.

"Chiller" water set-point compensation due

to external temp.

Adaptation of the unit set point depending

on the external temperature, allowing

greater comfort and energy saving. The

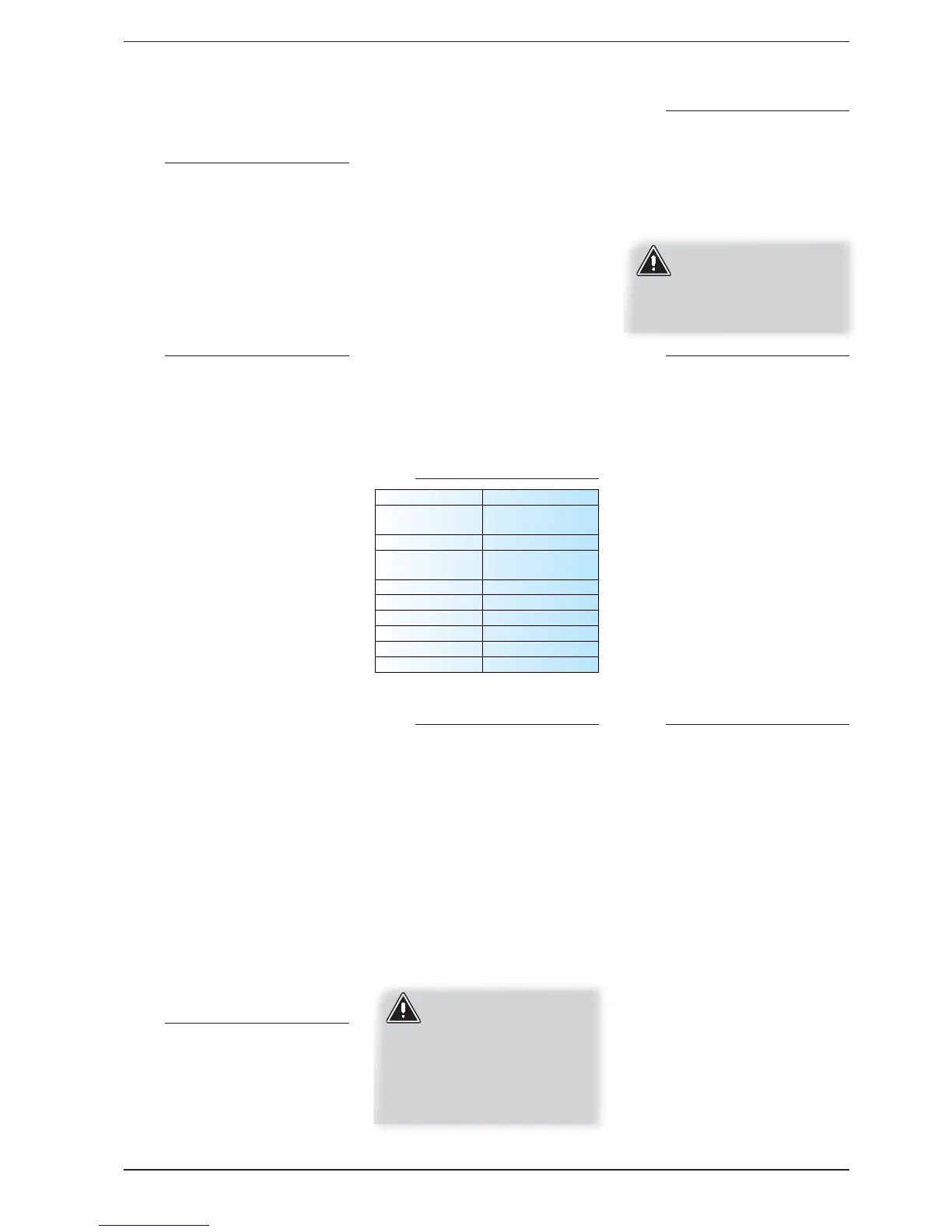

PH 6-8

Electric

conductivity

less than 200 mV/

cm (25°C)

Chloride ions less than 50 ppm

Sulphuric acid

ions

less than 50 ppm

Total iron less than 0.3 ppm

Alkalinity M less than 50 ppm

Total hardness less than 50 ppm

Sulphur ions none

ammonia ions none

Silicone ions less than 30 ppm

9

IWRLTY. 1201. 5890974_06

Loading...

Loading...