Maintenance, Spare Parts and Troubleshooting

50 Agilent Microwave Plasma Atomic Emission Spectrometers User’s Guide

Cleaning the Spray Chamber

The ‘wetting’ of a spray chamber is its ability to produce a uniform

coating of aerosol on the internal surfaces of the spray chamber. This

uniform coating is essential for the efficient transport of aerosol from

the spray chamber to the plasma torch.

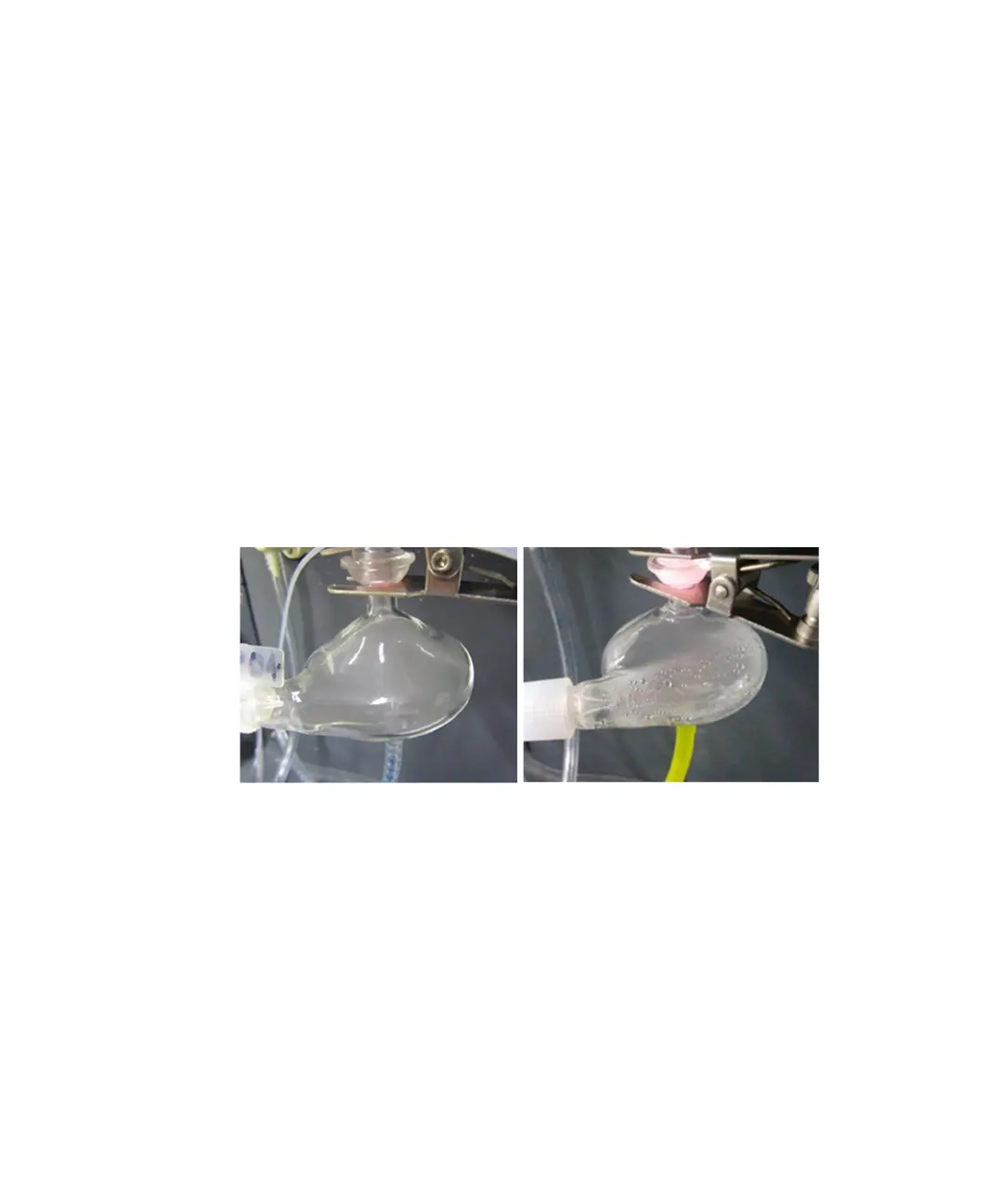

The “wetting” of a spray chamber can be judged by observing the

internal surfaces of the spray chamber while an acidified aqueous

solution (typically 1-5%) is nebulized. A correctly ‘wetting’ spray

chamber shows a uniform internal surface without large droplet

formation (Figure 6).

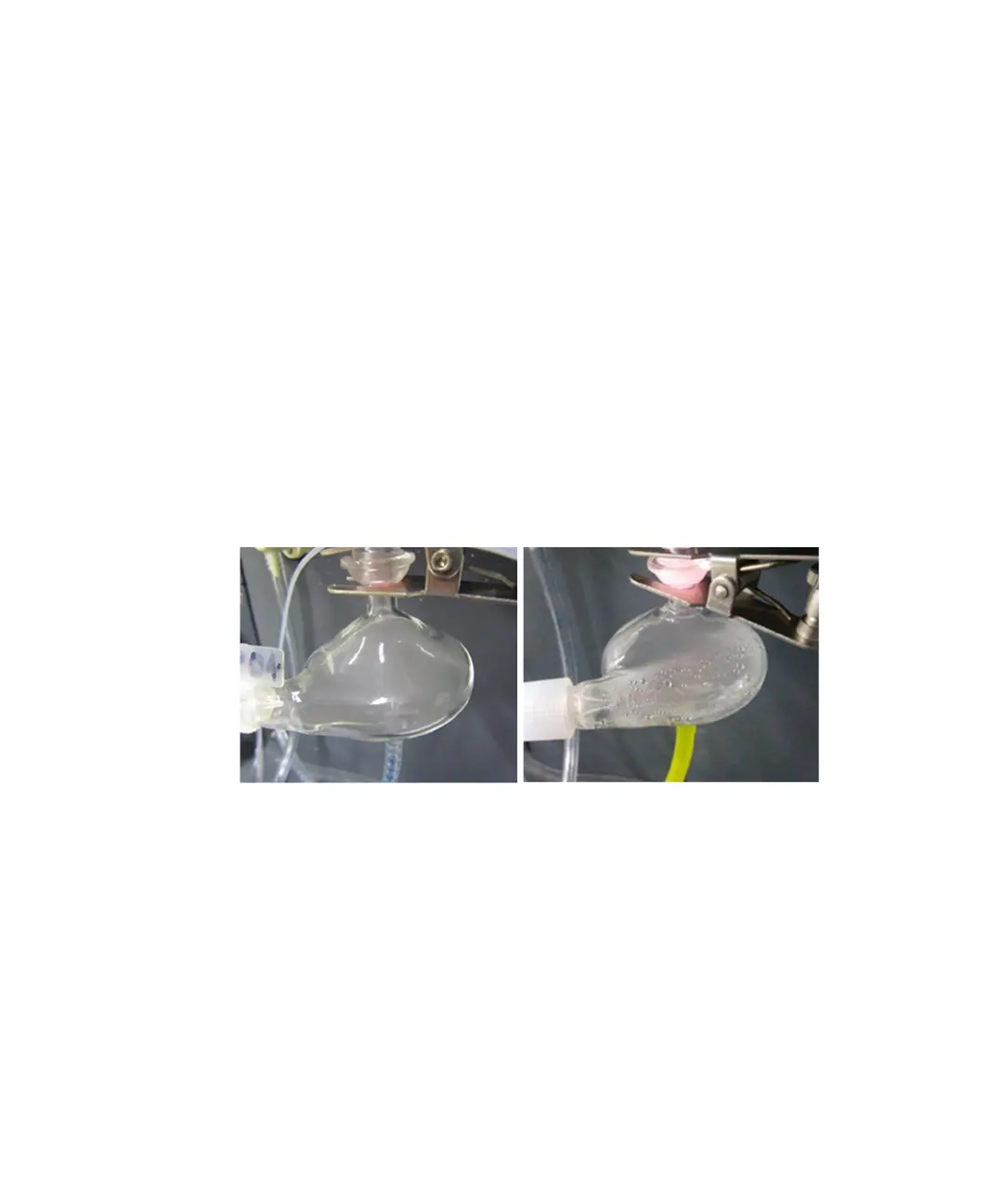

A poor ‘wetting’ spray chamber is usually indicated by the

appearance of large droplets on the internal surfaces of the spray

chamber (Figure 7) and can be caused by the analysis of water

miscible organic samples, contamination of the spray chamber, or

improper handling or storage.

Figure 6. Correctly ‘wetting’ spray

chamber with a uniform coverage

Figure 7. Incorrectly ‘wetting’ spray

chamber showing droplets

A poor ‘wetting’ spray chamber can be fixed with thorough cleaning.

For detailed spray chamber cleaning instructions, see the MP Expert

Help. Click ‘Maintenance’ and then select ‘Cleaning the spray

chamber’.

Loading...

Loading...