31

Order online at www.agilent.com/chem/store

Sample Introduction

Cleaning Syringes During an Autosampler Sequence

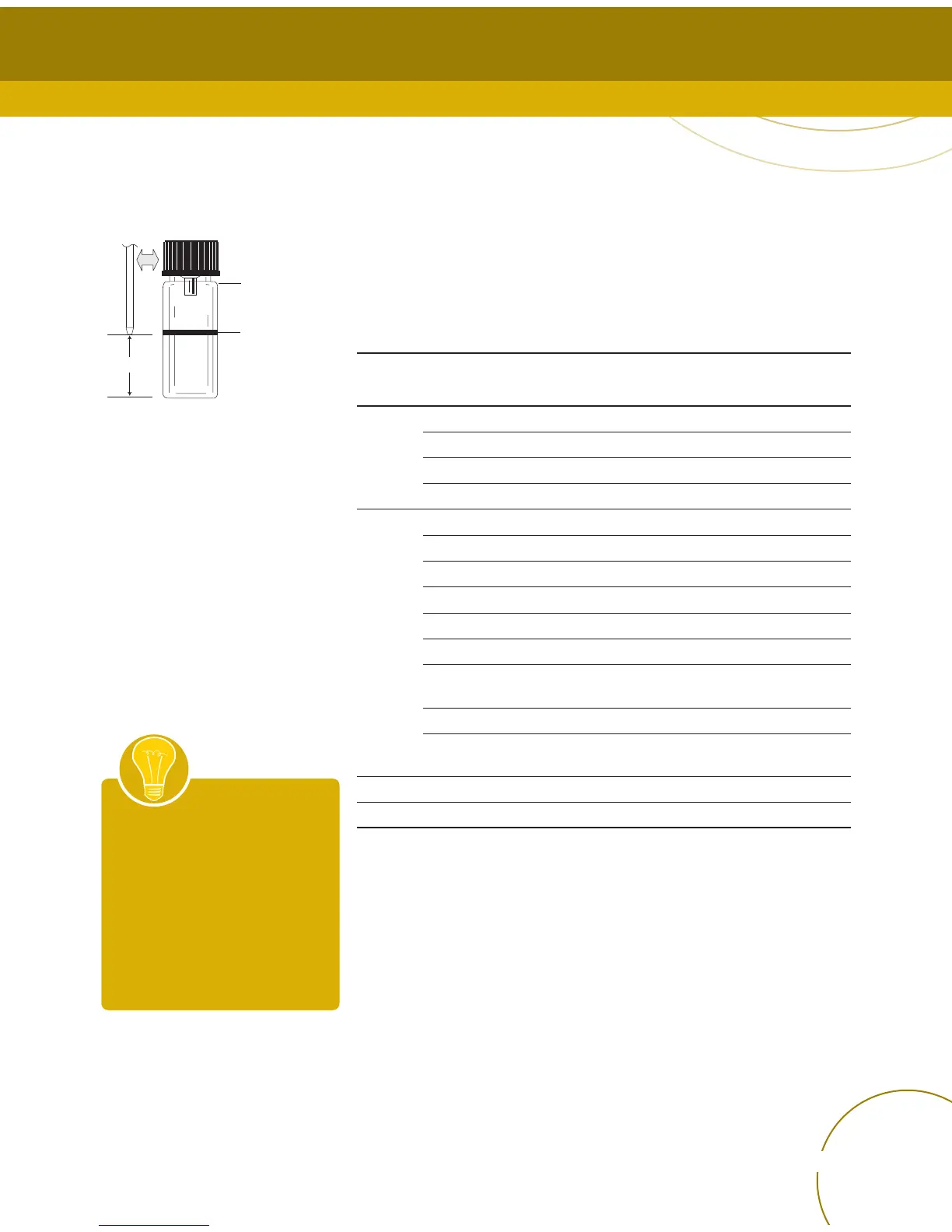

To ensure the syringe is properly cleaned between injections, rinse and fill each solvent

bottle with 4 mL of fresh solvent. The liquid level will be near the shoulder of the bottle.

Good laboratory practice dictates using no more than 2 mL of the 4 mL solvent for syringe

washes. The needle tip draws solvent 18.5 mm from the bottom of the vial.

Tapered Needle, 23-26s Gauge Autosampler Syringes

Volume

(µL)

Description Unit Needle Part No.

5 Tapered, fixed 23-26s/42/HP 5181-1273

Tapered, fixed 6/pk 23-26s/42/HP 5181-8810

Tapered, removable 23-26s/42/HP 5182-0835

Replacement needle for 5 µl syringe 3/pk 23-26s/42/HP 5182-0832

10 Tapered, fixed 23-26s/42/HP 5181-1267

Tapered, fixed 6/pk 23-26s/42/HP 5181-3360

Tapered, removable 23-26s/42/HP 5181-3321

Replacement needle for 10 µl syringe

3/pk 23-26s/42/HP 5181-3319

Tapered, fixed, PTFE-tipped plunger 23-26s/42/HP 5181-3354

Tapered, fixed, PTFE-tipped plunger 6/pk 23-26s/42/HP 5181-3361

Replacement plunger with PTFE tip

for fixed needle 10 µl syringe

5181-3365

Tapered, removable 23-26s/42/HP 5181-3356

Replacement plunger with PTFE tip

for removable needle 10

µl syringe

5181-3358

50 Tapered, fixed, PTFE-tipped plunger 23-26s/42/HP 5183-0314

100 Tapered, fixed, PTFE-tipped plunger

23-26s/42/HP 5183-2042

Tips & Tools

When cleaning syringes between

injections, use Agilent wash vials

(p/n 9301-0723) and diffusion

caps (p/n 07673-40180).

18.5 mm

4

mL fill volume

2.0 mL usable

s

olvent volume

Minimum solvent level

2.0 mL solvent

remains

N

eedle tip position when withdrawing solvent

Loading...

Loading...