10

within a wooden frame and are based on 100 mm.

Acoustic modules. The attenuators should be fitted

with weather louvers with a minimum 50 % free area,

good airflow profile and afford l

ow restriction airflow access.85dB(A) noise level at 1

m will be obtained by using noise level attenuators in

order to meet EEC standard regulation .if you want to

decrease the noise level more than that ,increase the

length of the attenuators.

The weather louvers should have bird/vermin mesh

screens fitted on the inside, but these screens must

not impede the free flow of cooling and aspiration air.

The outlet attenuator should be connected to the ra-

diator ducting flange with a heat and oil resistant flex-

ible connection.

Combustion Air Inlet

Air for engine combustion must be clean and as cool

as possible. Normally this air can be drawn from the

area

surrounding the generating set via the engine mounted

air filter. However, in some cases due to dust, dirt

or heat the air around the set is unsuitable. In these

cases an inlet duct should be fitted. This duct should

run from the source of clean air (outside the building,

another room, etc) to the engine mounted air filter

Exhaust systems

The exhaust systems shown on the layout drawings

are supported from the ceiling. Should the building

construction be such that the roof supports were

unable to support the exhaust system, a floor stand-

ing steel exhaust stand will be needed. Exhaust pipes

should terminate at least 2,3 m above floor level to

make it reasonable safe for anyone passing or acciden-

tally touching. It is recommended that stainless steel

bellows be fitted to the engine exhaust manifold fol-

lowed by rigid pipe work to the silencer. It is good

installation practice for the exhaust system within the

generator room to be insulated with a minimum of 50

mm. of high density, high temperature mineral insula-

tion covered by an aluminium over clad. This reduced

the possibility of operator burn injury and reduces the

heat being radiated to the operating generator room.

Cooling and Ventilation

The engine, alternator and exhaust piping radiate heat

which can result in a temperature high enough to ad-

versely affect the performance of the generator set. It

is therefore important that adequate ventilation is pro-

vided to keep the engine and alternator cool. Proper

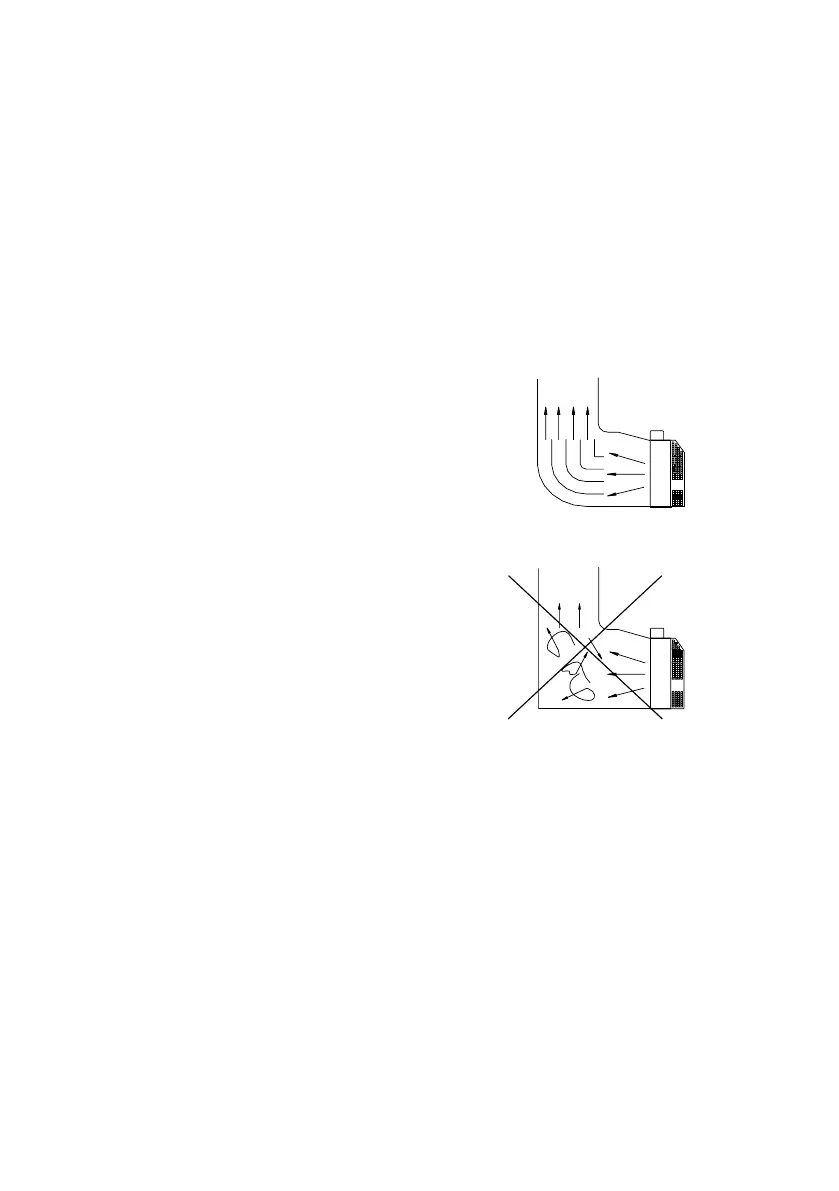

air flow, as shown in Figure 5.4. requires that the air

comes in at the alternator end of the set, passes over

the engine, through the radiator and out of the room

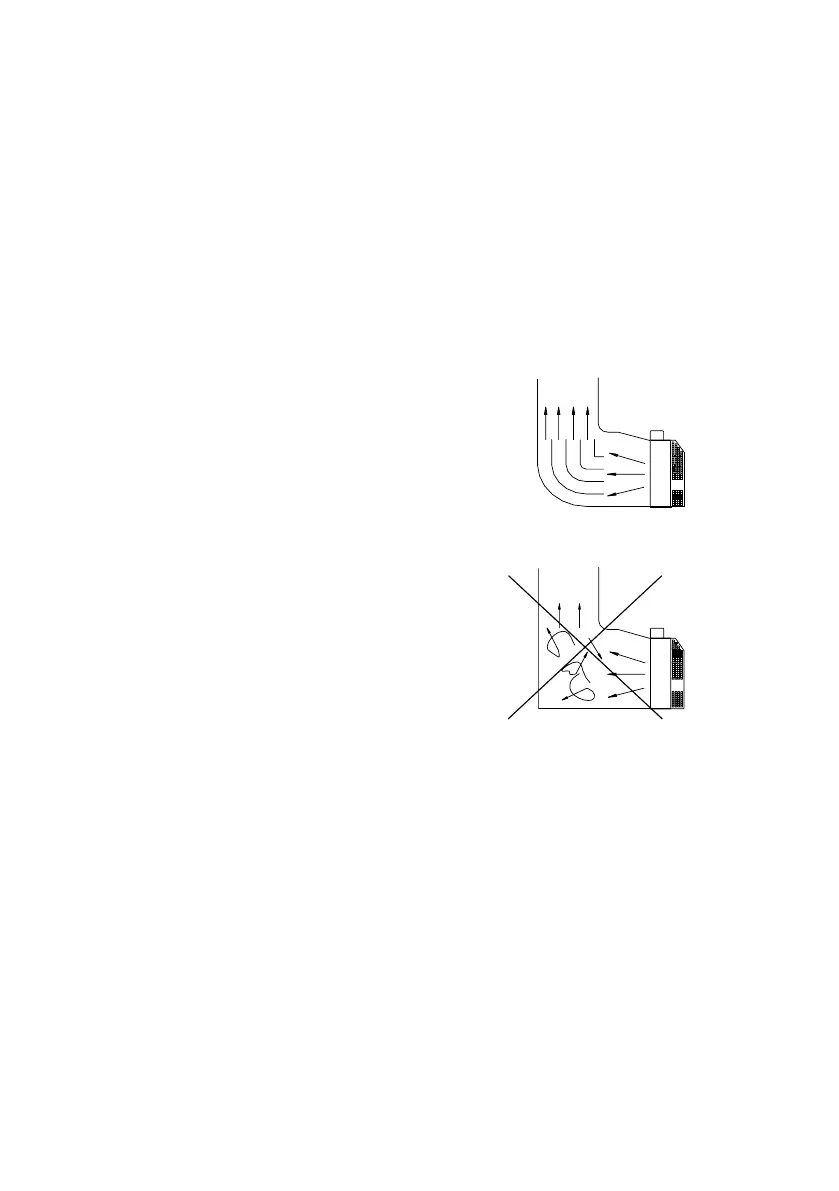

via a flexible exhaust duct. Without the ducting of the

hot air outside the room, the fan will tend to draw that

hot air around and back through the radiator, reducing

the cooling effectiveness.

Figure 5.3. Directing the air thrown from the radiator

with deviating wings.

Figure 5.4. Weak ventilation

Sharp corners on the radiator hot air outlet or its chim-

ney must be avoided. some rearrangements should be

done to change the direction of the air comes out of

radiator.

The air inlet and outlet openings should be large

enough to ensure free flow of air into and out of the

room. As rough guide the openings should each be

at least 1,5 times the area of the radiator core. Both

the inlet and outlet openings should have louvers for

weather protection.

Loading...

Loading...