Alfa Laval Copenhagen A/S

ALF – Installation, Operating and Safety Manual

ALF Instruction Manual UM_Filter_100B03

Page 28 of 67

6.6 ALF Filter Start, Operation and Shut down – Siemens S7

Type

The following procedure should be carried out after initial installation and / or after

each periodic service and maintenance.

Prior to carrying out the commissioning procedure, make sure that the filter is put off

stream and is depressurized and properly drained.

A. Turn the panel power supply main switch ON. (or local safety switch – option)

B. Operating time intervals are selected by time selector in the control cabinet.

C. Ensure that no alarms are active/un-acknowledged.

D. Press the filter START (filter system / system run) push button. A flushing

sequence is initiated.

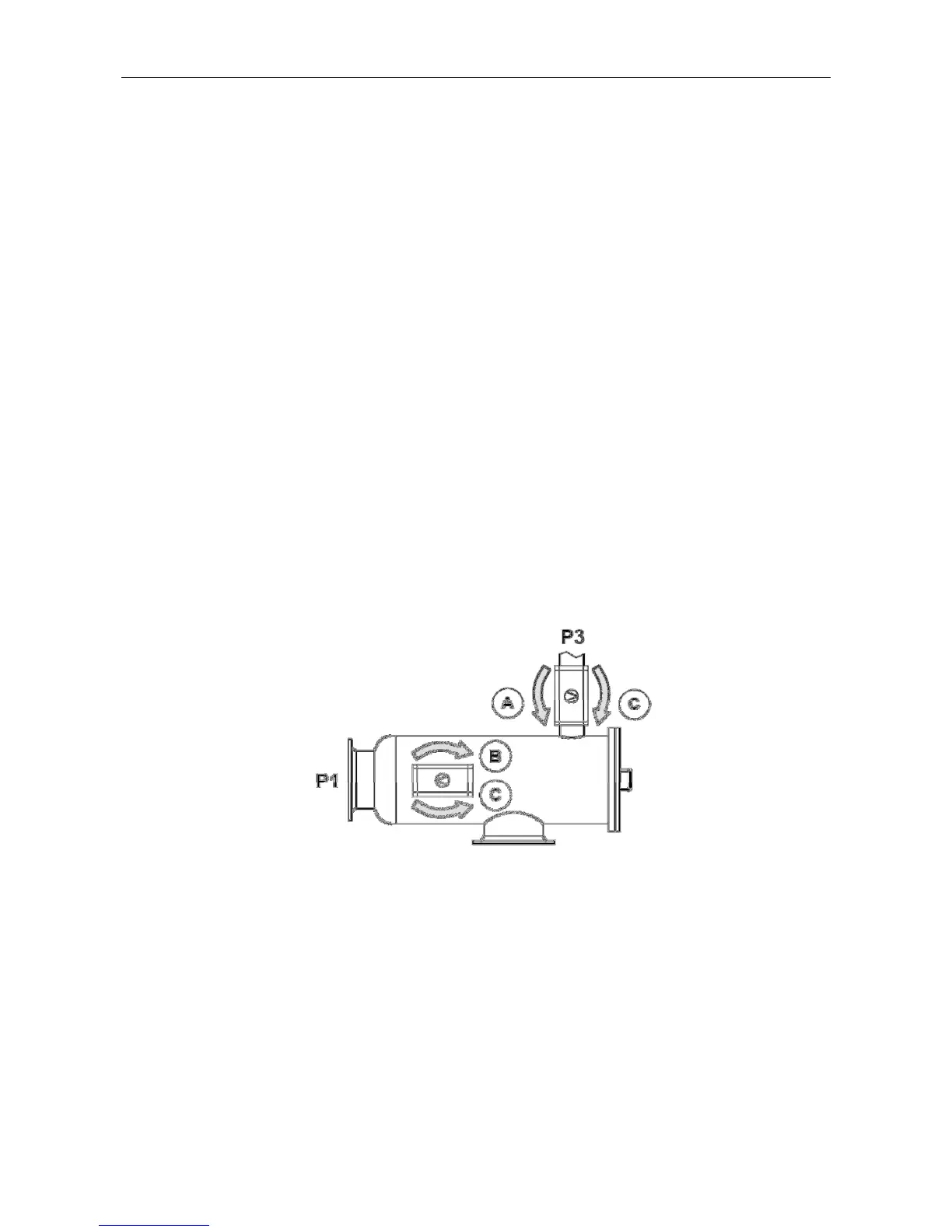

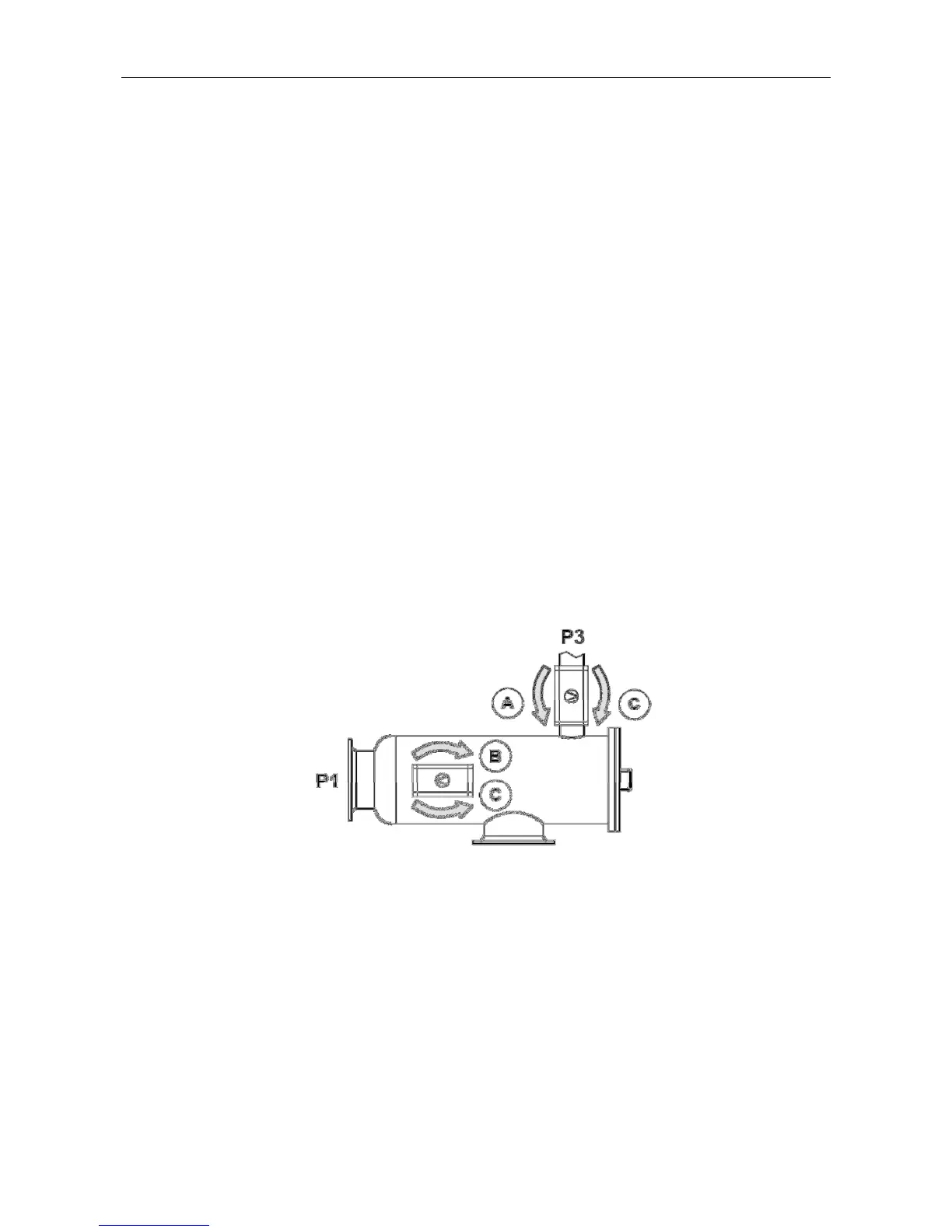

E. Check the operation of both the actuators during the flushing sequence to see

whether cables and/or air hoses have been connected properly or not (see figure

below):

1 Flushing valve actuator opens counter clockwise (primary flushing).

2 Flow diverter valve actuator closes clockwise (secondary flushing / back

flushing).

3 Both actuators returns to “normal operation” position simultaneously.

F. Normal operation position for each valve (not the actuators) is:

Flushing Valve = Closed

Flow Diverter = Open

Pneumatic actuators only:

All actuators are equipped with throttle valves (air restrictors) for a smooth operation. Air-supply to

the actuators and the solenoid valves must be dry and clean.

Compressed air quality must be:

Oil content: max 10 mg/dm³.

Water content: none - use a water separator.

Solid particles: max. 0.01 mm.

Operation pressure: Min. 5.0 barg. / Max. 10.0 barg.

G. Check the function of the limit switches to make sure that the cables have been

properly connected. Position of the actuator can be seen on the display.

• Repeat the above sequence to check the actuators and the limit switches

together with the other relays if the panel is controlling more than one ALF-

Filter. (optional)

Loading...

Loading...