Publication 2100-IN012B-EN-P - April 2005

4-4 Installing Conduit and Cable

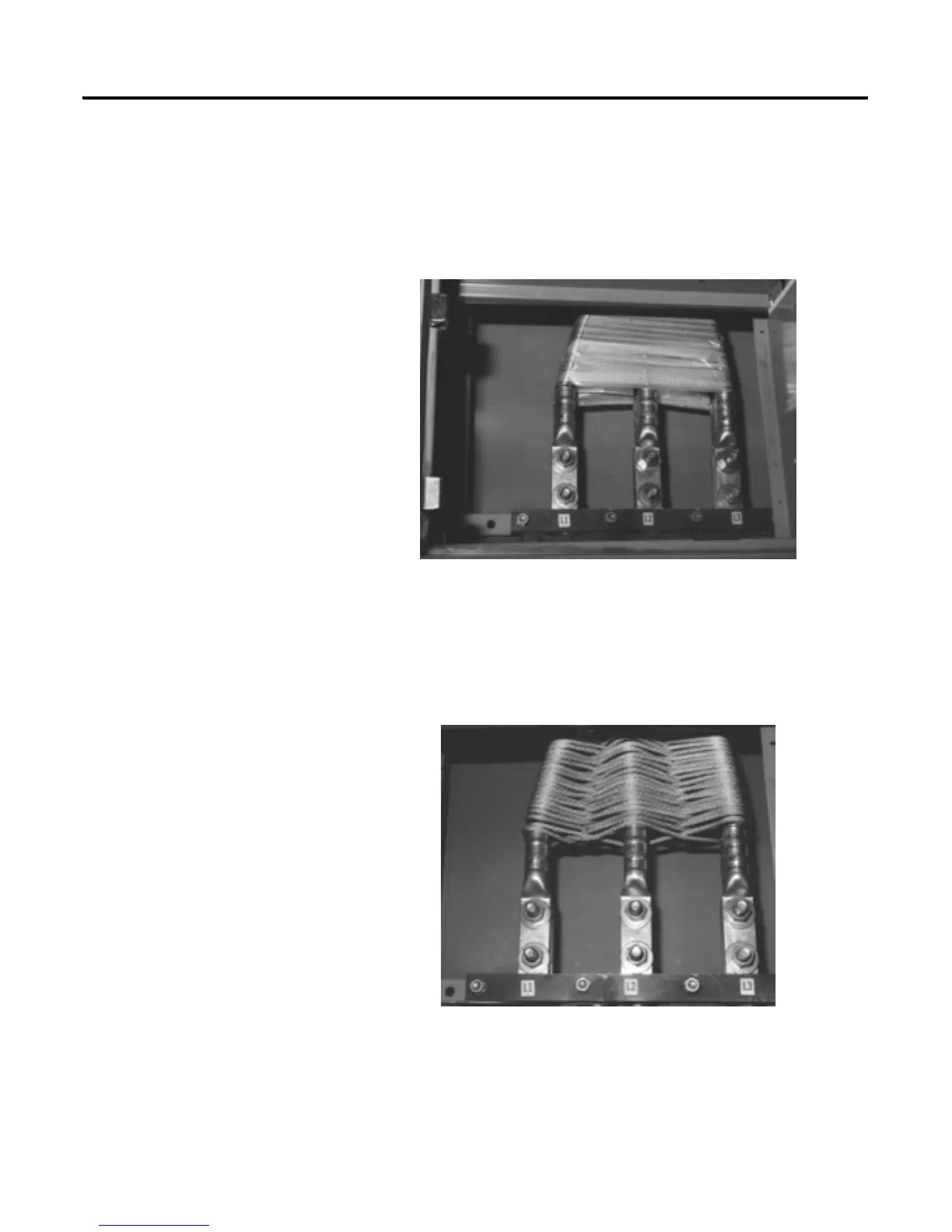

In Figure 4.1, glass fiber reinforced tape or glass filament tape is used. The

taping should be continuous from the point the cables enter the MCC to the

point the cables are terminated. It is important that cables are wrapped several

times for additional strength. Cable slack should be drawn up during wrapping

so that individual cables are supported by the tape as a single mass.

Figure 4.1 Securing Cables with Glass Tape

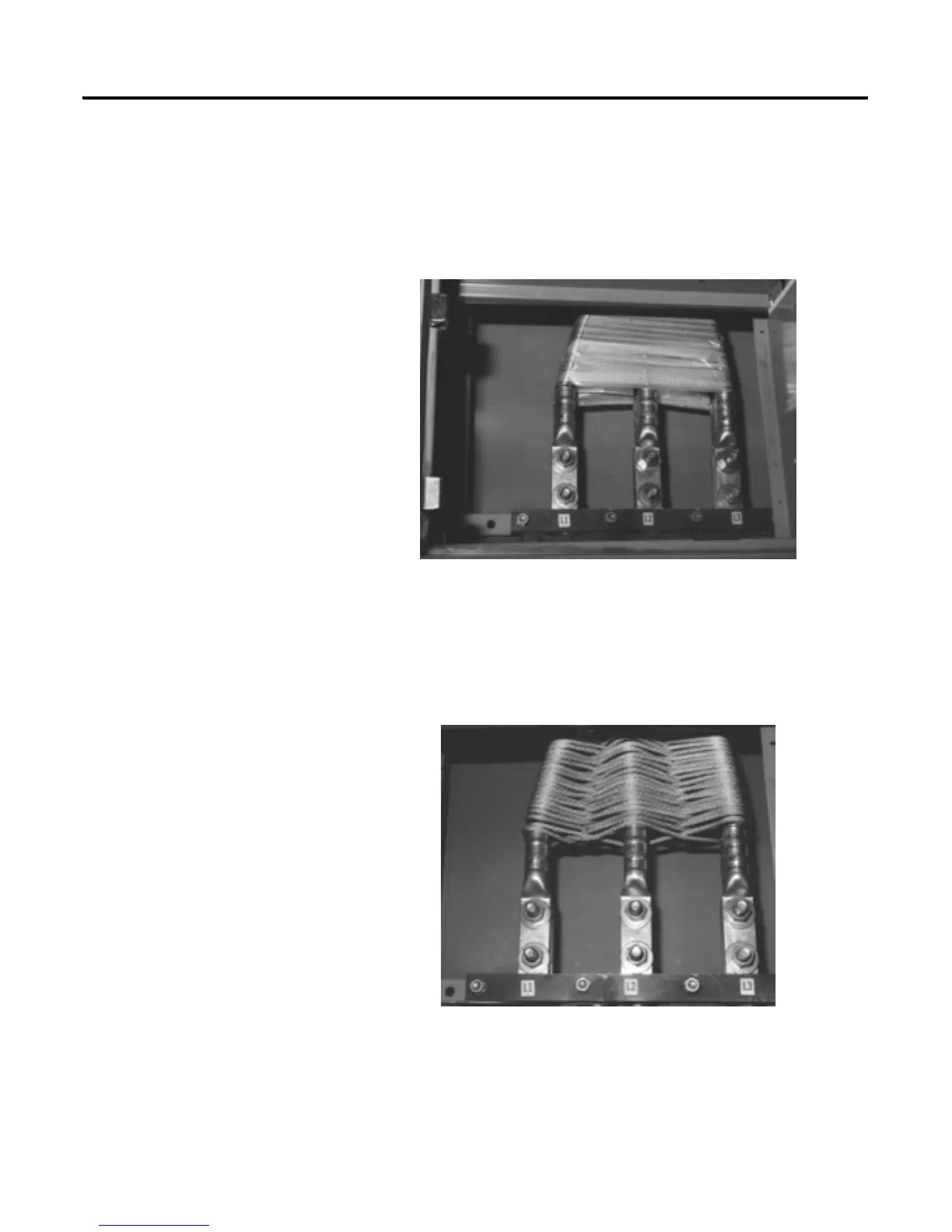

In Figure 4.2, cables are lashed in a “figure 8”-type configuration using nylon

rope. The rope lashing should be continuous from the point the cables enter

the MCC to the point the cables are terminated. Other types of rope lashing

may be acceptable. Cable slack should be drawn up during wrapping so that

individual cables are supported by the rope as a single mass.

Figure 4.2 Securing Cables with Nylon Rope

Loading...

Loading...