Publication 2100-IN012B-EN-P - April 2005

2-6 Installation Procedures

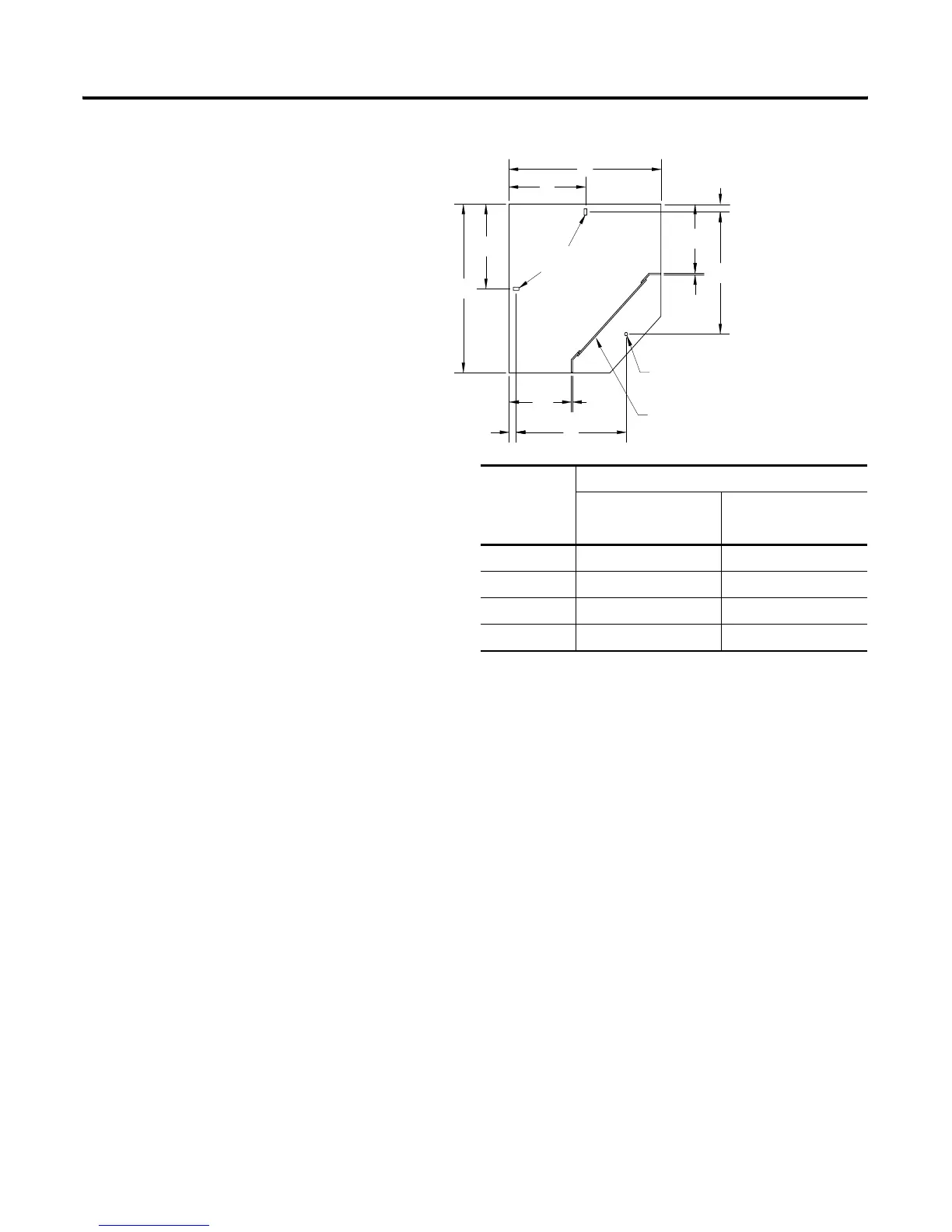

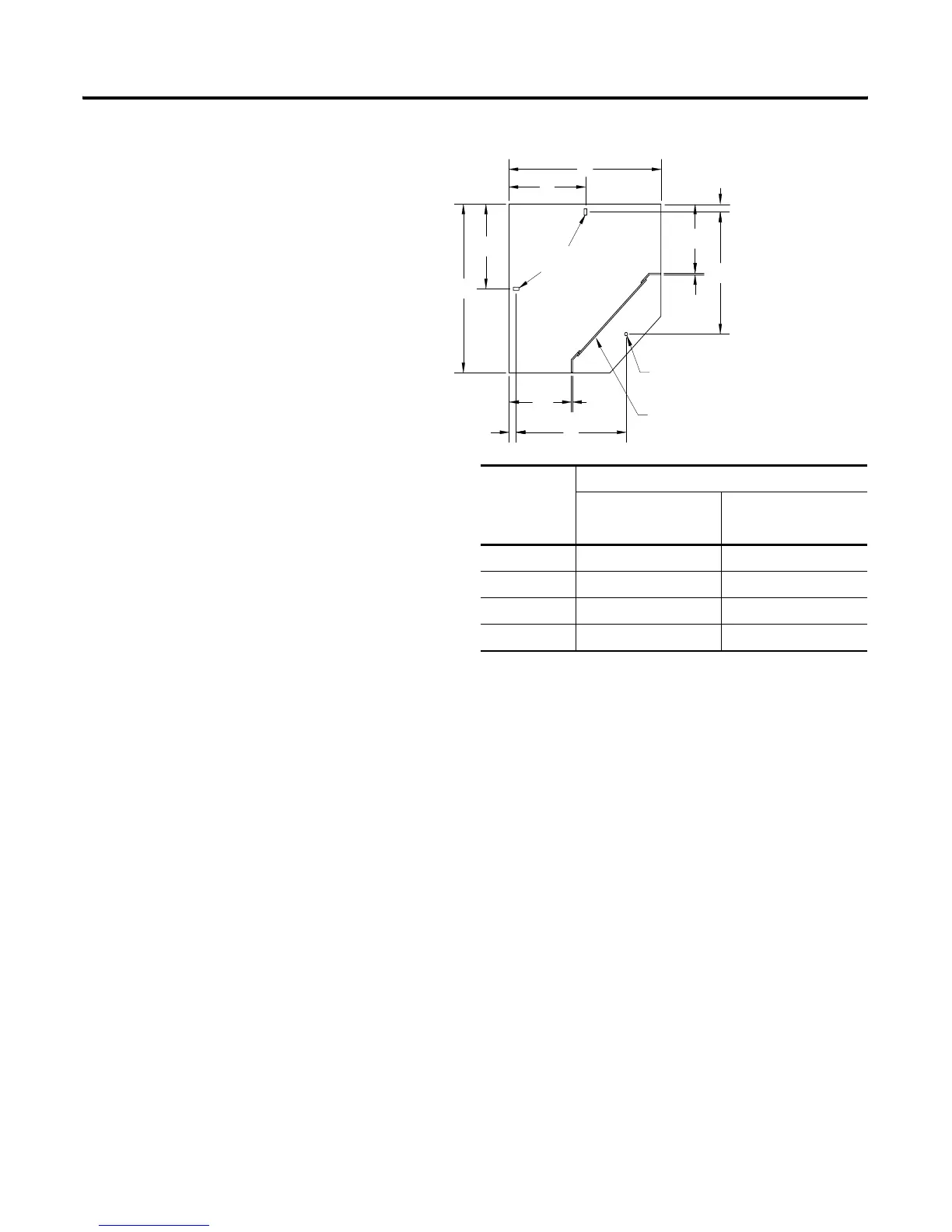

Figure 2.6 Mounting Dimensions for 15” and 20” Deep Corner Section

NOTE: Documentation packages shipped with assembled MCCs include an

MCC elevation drawing showing an MCC floor plan layout.

Seismic Requirements

To demonstrate the seismic withstand of various CENTERLINE Motor

Control Centers (15” deep [380 mm], 20” deep [508 mm], 30” deep [762 mm]

back-to-back and 40” deep [1016 mm] back-to-back), the MCC design

construction has been qualified by seismic calculations per the Uniform

Building Code (UBC). The CENTERLINE seismic withstand has been

qualified by subjecting MCC samples to static and dynamic (triaxial

multi-frequency testing) seismic tests. The results of this evaluation and testing

qualify the CENTERLINE MCC of sufficient integrity to exceed a Zone 4

seismic withstand per the UBC's requirements, i.e. neither the MCC structure,

units, components or electrical functions will be compromised when subjected

to a Zone 4 seismic event.

NOTE: Zone 4 is the maximum UBC seismic magnitude.

To obtain a UBC Zone 4 seismic withstand rating, each CENTERLINE MCC

line-up (i.e., both front and back MCCs in back-to-back applications) must be

mounted on an adequate seismic foundation and installed per the seismic

anchoring requirements. See Figure 2.7 for bolt down dimensions. See Figure

2.8 for weld down securing.

Section Depth

Dimension 15” (381mm) Deep 20” (635mm) Deep

in (mm) in (mm)

A 25.13 (638) 30.13 (765)

B 12.63 (321) 15.13 (384)

C 16.81 (427) 21.81 (554)

D 17.62 (448) 22.62 (575)

(1) Mounting Holes

.63" (16mm) diameter

A

B

C

1.41" (3.58mm)

C

D

.25" (6mm)

.25" (6mm)

D

1.41" (36mm)

(2) Mounting Slots

.56" X 1.13" Slot

(14mm) X (29mm) slot

B

A

Ground Bus

Loading...

Loading...