Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 159

Specifying the Cam Profile Tag

To execute a MAPC instruction, a Cam Profile array tag must also be created.

Cam Profile array tags may be created by the Logix Designer tag editor or the

MAPC/MATC instructions using the built-in Cam Profile Editor.

The data within the Cam Profile array can be modified at compile time using the

Cam Profile Editor, or at run-time with the MCCP instruction. In the case of

run-time changes, a Cam array must be created in order to use the MCCP

instruction.

The status parameter is used to indicate that the Cam Profile array element has

been calculated. If execution of a camming instruction is attempted using any

uncalculated elements in a cam profile, the MAPC or MATC instructions error.

The type parameter determines the type of interpolation applied between this cam

array element and the next cam element.

Cam Profile Array Status Member

The Status member of the first element in the cam profile array is special and used

for data integrity checks. For this reason, the MCCP must always specify the cam

profile with the starting index set to 0. This first cam profile element Status

member can have the following values.

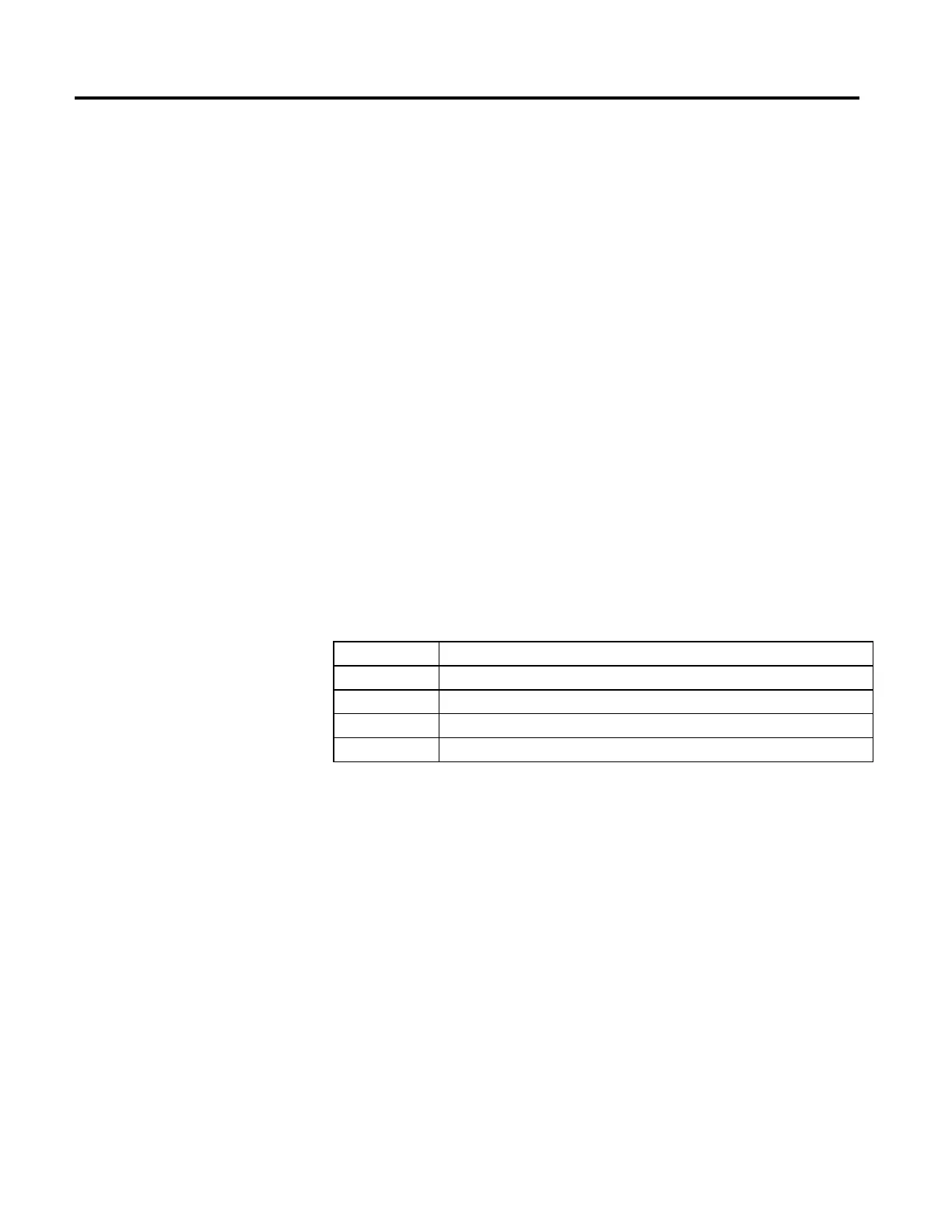

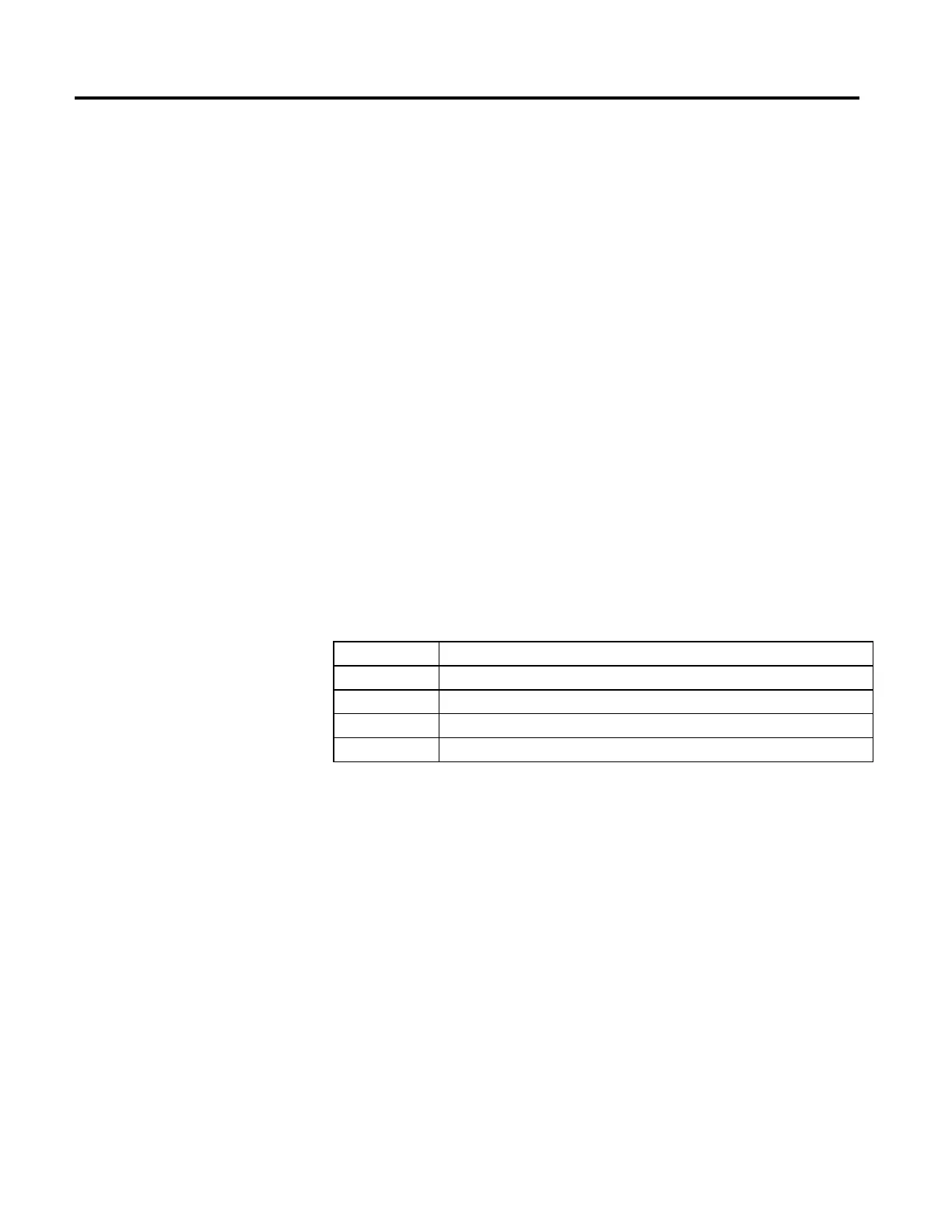

Status Variables Description

0 Cam profile element has not been calculated.

1 Cam profile element is being calculated.

2 Cam profile element has been calculated.

n Cam profile element has been calculated and is currently being used by (n-2) or MATC instructions.

Linear and Cubic Spline Interpolation

The resultant calculated cam profiles are fully interpolated. This means that if the

current master position or time does not correspond exactly with a point in the

cam array used to generate the cam profile, the slave axis position is determined by

linear or cubic interpolation between adjacent points. In this way, the smoothest

possible slave motion is provided. The MCCP instruction accomplishes this by

calculating coefficients to a polynomial equation that determines slave position as

a function of master position or time.

Calculating the Cam Profile

Before calculating a cam profile on a specified axis, the MCCP instructions first

checks if the cam profile array has been calculated by checking the value of the first

cam profile element’s Status member. If the Status value is either 0 or 2, the

MCCP proceeds with the calculation of the cam profile. When the cam profile

array has been completely calculated, the MCCP instruction sets the first cam

Loading...

Loading...