Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 171

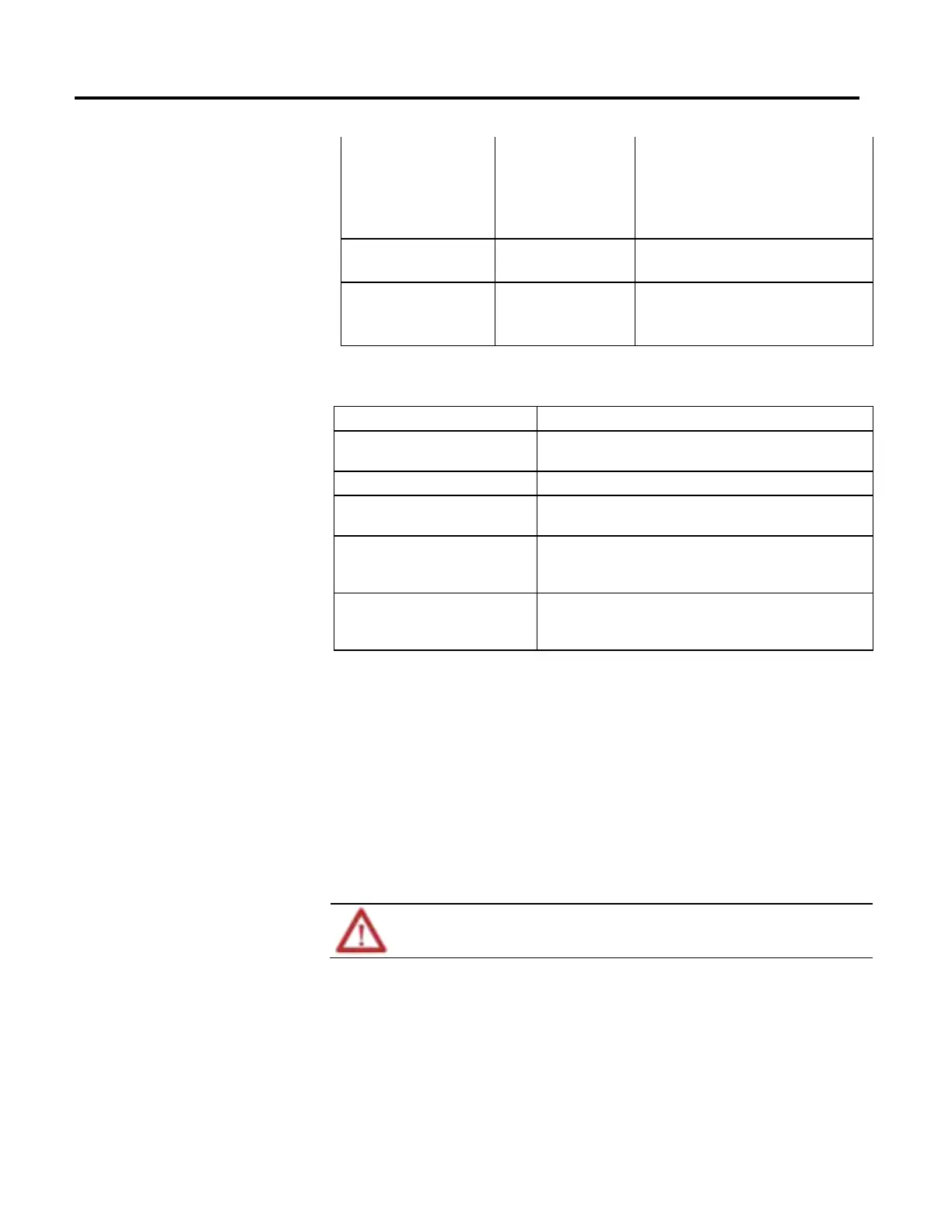

ExecutionSchedule immediate

pending

forwardonly

reverseonly

bidirectional

0

1

2

3

4

MasterReference actual

command

0

1

MasterDirection bidirectional

forwardonly

reverseonly

0

1

2

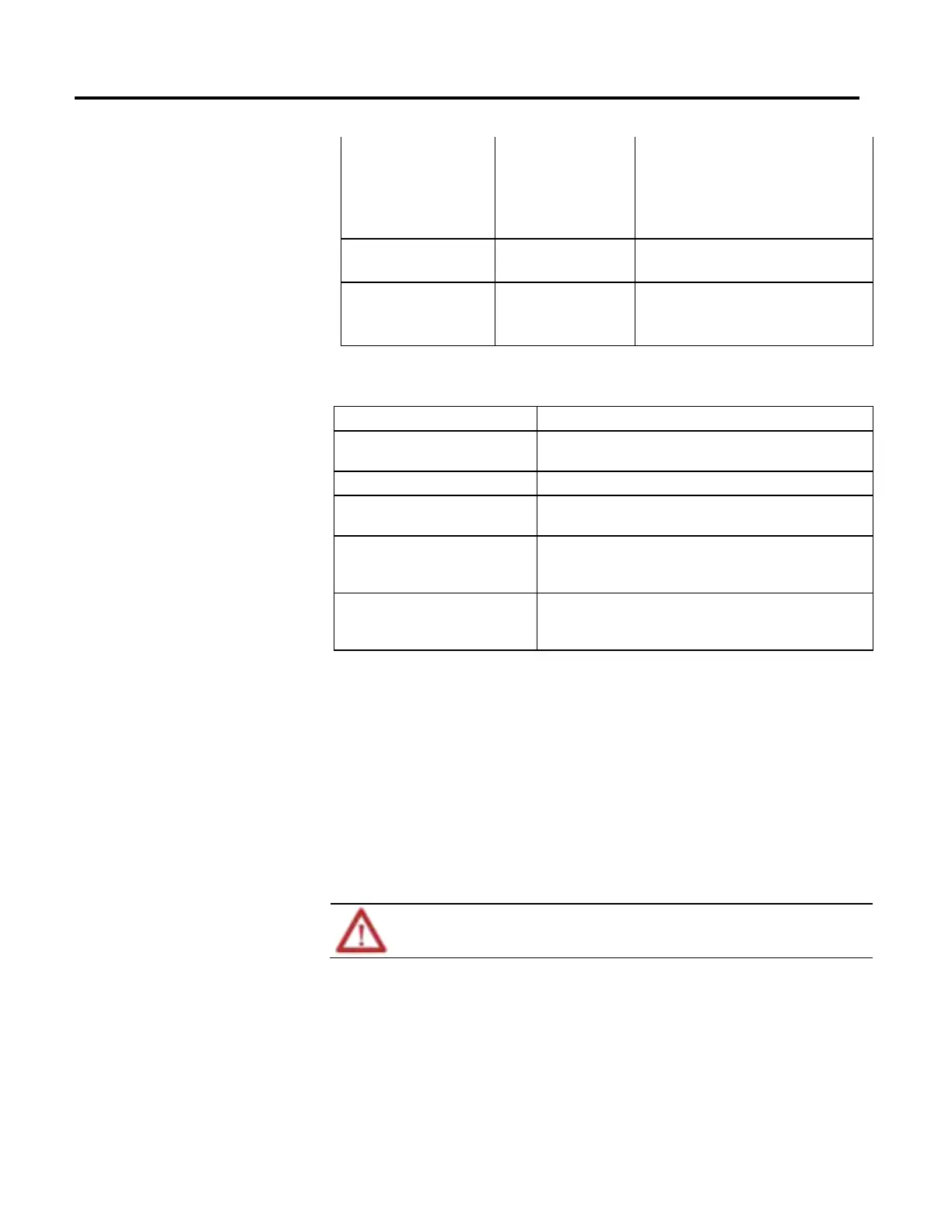

MOTION_INSTRUCTION Structure

Mnemonic Description

.EN (Enable) Bit 31

It is set when the rung makes a false-to-true transition and remains set until

the rung goes false.

.DN (Done) Bit 29 It is set when the axis' position cam has been successfully redefined.

.ER (Error) Bit 28

It is set to indicate that the instruction detected an error, such as if you

specified an unconfigured axis.

.IP (In Process) Bit 26

It is set on positive rung transition and cleared if either superseded by

another Motion Axis Position Cam command, or terminated by a stop

command, merge, shutdown, or servo fault.

.PC (Process Complete) Bit 27

It is cleared on positive rung transition. It is set when the position of the

master axis leaves the master position range defined by the currently active

cam profile if Execution Mode = Once.

Description

The MAPC instruction executes a position cam profile set up by a previous

Motion Calculate Cam Profile (MCCP) instruction or, alternatively, by the Logix

Designer application Cam Profile Editor. Position cams, in effect, provide the

capability of implementing non-linear electronic gearing relationships between

two axes. No maximum velocity, acceleration, or deceleration limits are used. The

speed, acceleration, and deceleration of the slave axis are completely determined by

the motion of the master axis and the designated cam profile derived from the

associated cam table.

The maximum velocity, acceleration, or deceleration limits established during axis configuration do not

apply to electronic camming.

The direction of Slave Axis motion relative to the Master Axis is defined by a

flexible Direction input parameter. The camming direction, as applied to the slave,

may be explicitly set as the Same or Opposite or set relative to the current

camming direction as Reverse or Unchanged.

To accurately synchronize the slave axis position to master axis position, an

Execution Schedule setting and an associated Master Lock Position can be

specified for the master axis. When the master axis travels past the Master Lock

Loading...

Loading...