Motion Group Instructions

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 215

Each axis may be configured to use any of these five stop modes. The following is a

description of the effect of each these five stopping modes as they apply to an

individual axis in the specified group.

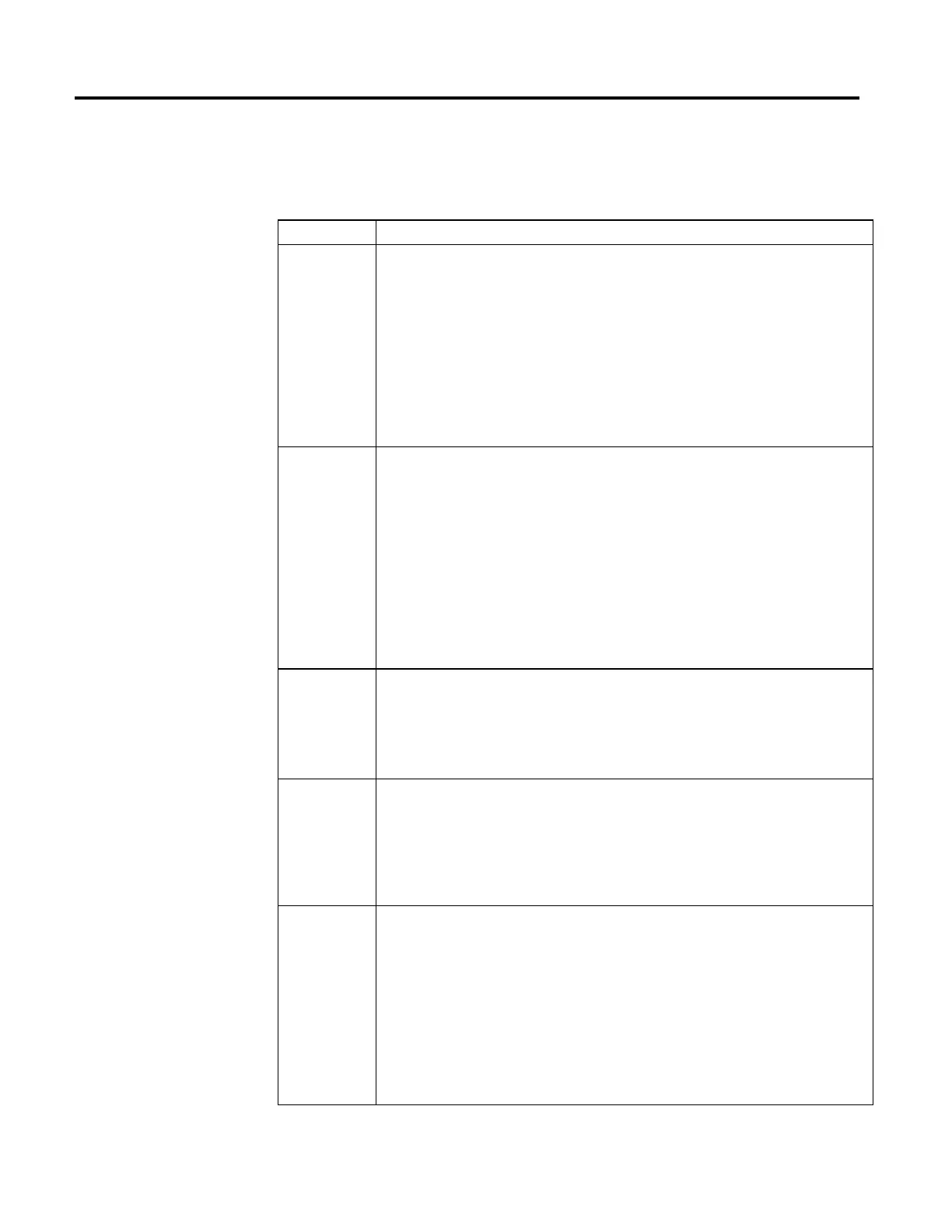

Mode Description

Fast Stop For an axis configured for a Fast Stop the MGS instruction initiates a controlled stop much like that initiated by an

MAS instruction. In this case the Motion Group Stop (MGS) instruction brings the axis motion to a controlled stop

without disabling the axis servo loop. It is useful when a fast decelerated stop the axis is desired with servo

control retained.

The MGS instruction uses the configured Maximum Deceleration of the axis to stop only the single axis motion.

The coordinated move portion of the axis uses the coordinated system configured Maximum Deceleration to stop

the axis.

If the coordinate system contains orientation axes, configured Maximum Orientation Deceleration is used to stop

orientation axes.

When a Fast Stop is used to stop a Motion Drive Start (MDS) instruction, the Direct Command feature is disabled.

Additionally, the affected axis decelerates to a stop using its ramp deceleration.

Fast Disable For an axis configured for a Fast Disable the MGS instruction initiates a controlled stop much like that initiated by

an MAS instruction with the exception that the drive is disabled when the axis comes to a stop. Use MGS when a

fast decelerated stop the axis is desired before the drive is disabled.

The MGS instruction uses the configured Maximum Deceleration of the axis to stop only the single axis motion.

The coordinated move portion of the axis uses the coordinated system configured Maximum Deceleration to stop

the axis.

If the coordinate system contains orientation axes, configured Maximum Orientation Deceleration is used to stop

orientation axes.

CIP Motion

When a Fast Disable is issued and a Direct Velocity command is issued via the MDS instruction, the CIP axis is

disabled when all planned motion is stopped. However, in this case, the drive device continues coasting or

stopping according to its Stop Action selection.

Hard Disable For an axis configured for a Hard Disable the MGS instruction initiates the equivalent of an MSF instruction to the

axis. This action immediately turns the appropriate axis drive output off, and disables the servo loop. Depending

on the drive configuration, this may result in the axis coasting to a stop but offers the quickest disconnect of drive

output power.

When a Hard Disable is used to stop a Motion Drive Start (MDS) instruction, the Direct Command feature is

disabled. Additionally, the affected axis is immediately disabled.

Fast Shutdown For an axis configured for a Fast Shutdown, the MGS instruction initiates a Fast Stop and then applies the

equivalent of a Motion Axis Shutdown (MASD) instruction to the axis. This action turns the appropriate axis driver

output OFF, disables the servo loop, opens any associated motion module’s OK contacts, and places the axis into

the Shutdown state.

When a Fast Shutdown is used to stop a Motion Drive Start (MDS) instruction, the Direct Command feature is

disabled. Additionally, the affected axis decelerates to a stop using its ramp deceleration is immediately

shutdown.

Hard Shutdown For an axis configured for a Hard Shutdown the MGS instruction initiates the equivalent of an Motion Axis

Shutdown (MASD) instruction to the axis. This action turns the appropriate axis drive output OFF, disables the

servo loop, opens any associated motion module OK contacts, and places the axis into the Shutdown state.

Depending on the drive configuration, this may result in the axis coasting to a stop but offers the quickest

disconnect of Drive power via the OK contacts.

To successfully execute a MGS instruction, the targeted group must be configured.

When a Hard Shutdown is used to stop a Motion Drive Start (MDS) instruction, the Direct Command feature is

disabled. Additionally, the affected axis is immediately shutdown.

Important: The instruction execution may take multiple scans to execute because it requires multiple coarse

updates to complete the request. The Done (.DN) bit is not set immediately, but only after the request is

completed.

Loading...

Loading...