Motion Group Instructions

214 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

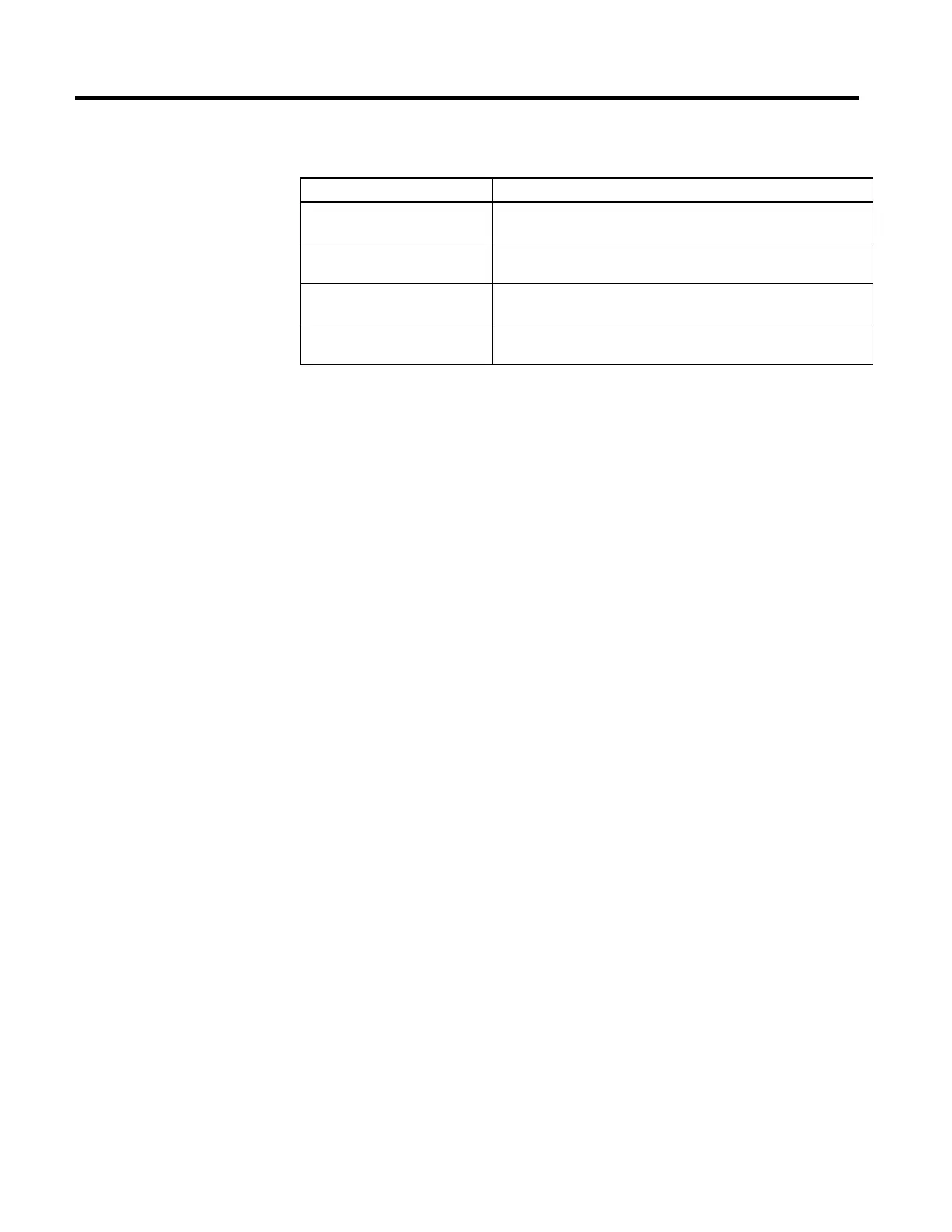

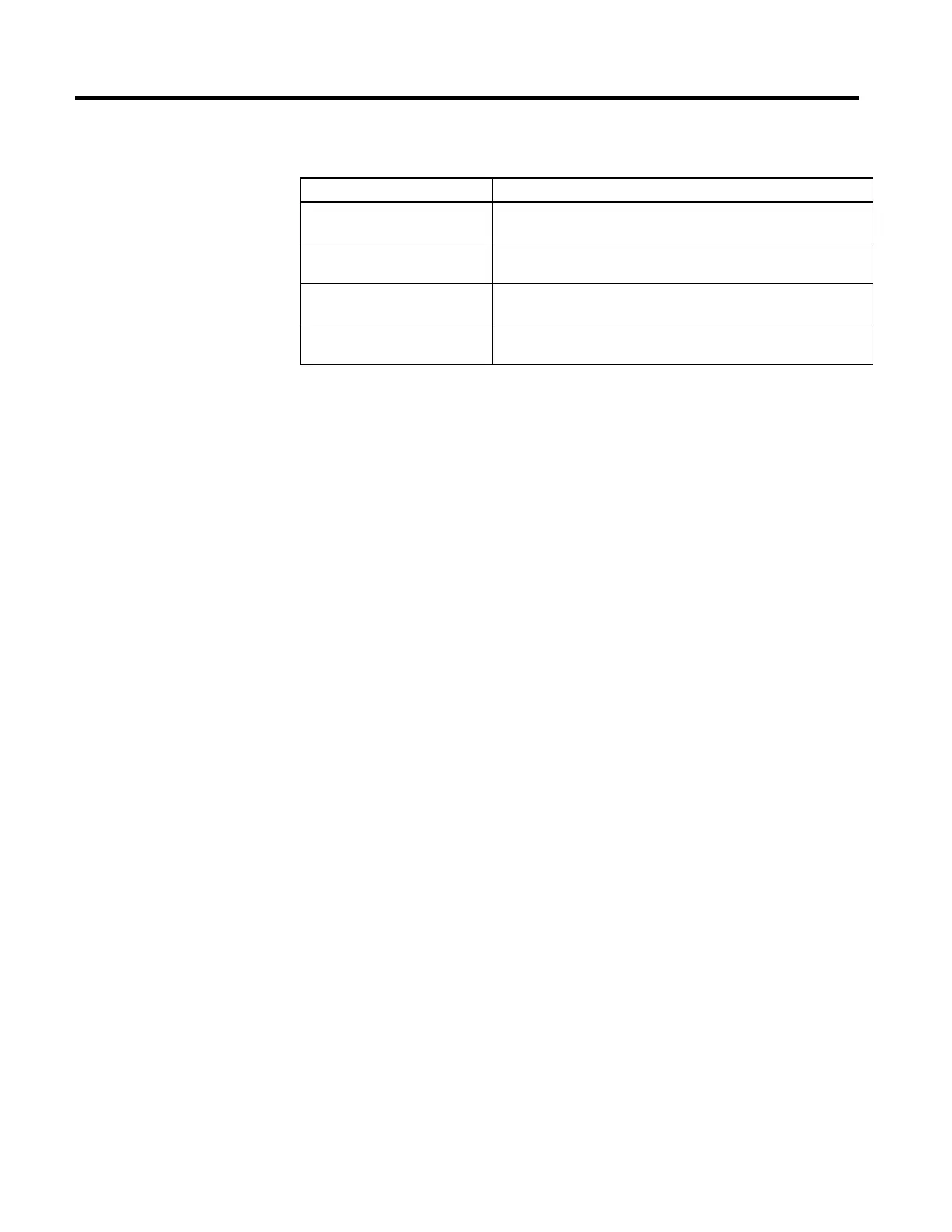

MOTION_INSTRUCTION Structure

Mnemonic Description

.DN (Done) Bit 29 It is set when the group Programmed Stop has been successfully initiated for all axes

in the group.

.ER (Error) Bit 28 It is set to indicate that the instruction detected an error, such as if you specified an

unconfigured group.

.IP (In Process) Bit 26 It is set on positive rung transition and cleared after the Motion Group Stop is

complete.

.PC (Process Complete) Bit 27 It is set after all the axes in group have been successfully brought to a stop according

to each axis’ Programmed Stop Mode configuration.

Description

With the Stop Mode parameter set for Programmed, the MGS instruction brings

motion for all of the axes in the specified group to a stop according to the

configured Programmed Stop Mode for each axis. If the axis has both single axis

motion moves and coordinated moves occurring, the MGS stops the single axis

motion using the axis’ maximum deceleration rate and stops the coordinated axes

motion using the coordinate system’s maximum deceleration rate. A trapezoidal

profile is always used for the deceleration regardless of the programmed profile

type.

The MGS instruction initiates the same programmed stopping action that is

automatically applied when the processor’s operating system changes operating

mode (for example, Run Mode to Program Mode). This is particularly useful in

designing custom motion fault handlers.

If the MGS Stop Mode parameter is set to Fast Stop, each axis in the group is

forced to perform a Fast Stop process, regardless of the configured Programmed

Stop Mode. Each axis in the group is decelerated at the Maximum Deceleration

rate and, once stopped, the axis is left in the Servo Active state.

If the MGS Stop Mode parameter is set to Fast Disable, each axis in the group is

forced to perform a Fast Disable process, regardless of the configured Programmed

Stop Mode. Each axis in the group is decelerated at the Maximum Deceleration

rate and, once stopped, placed into the Axis Ready (servo inactive and drive

disabled) state.

The MGS instruction currently supports five Programmed Stop Action modes:

• Fast Stop

• Fast Disable

• Hard Disable

• Fast Shutdown

• Hard Shutdown

Loading...

Loading...