Motion Event Instructions

238 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

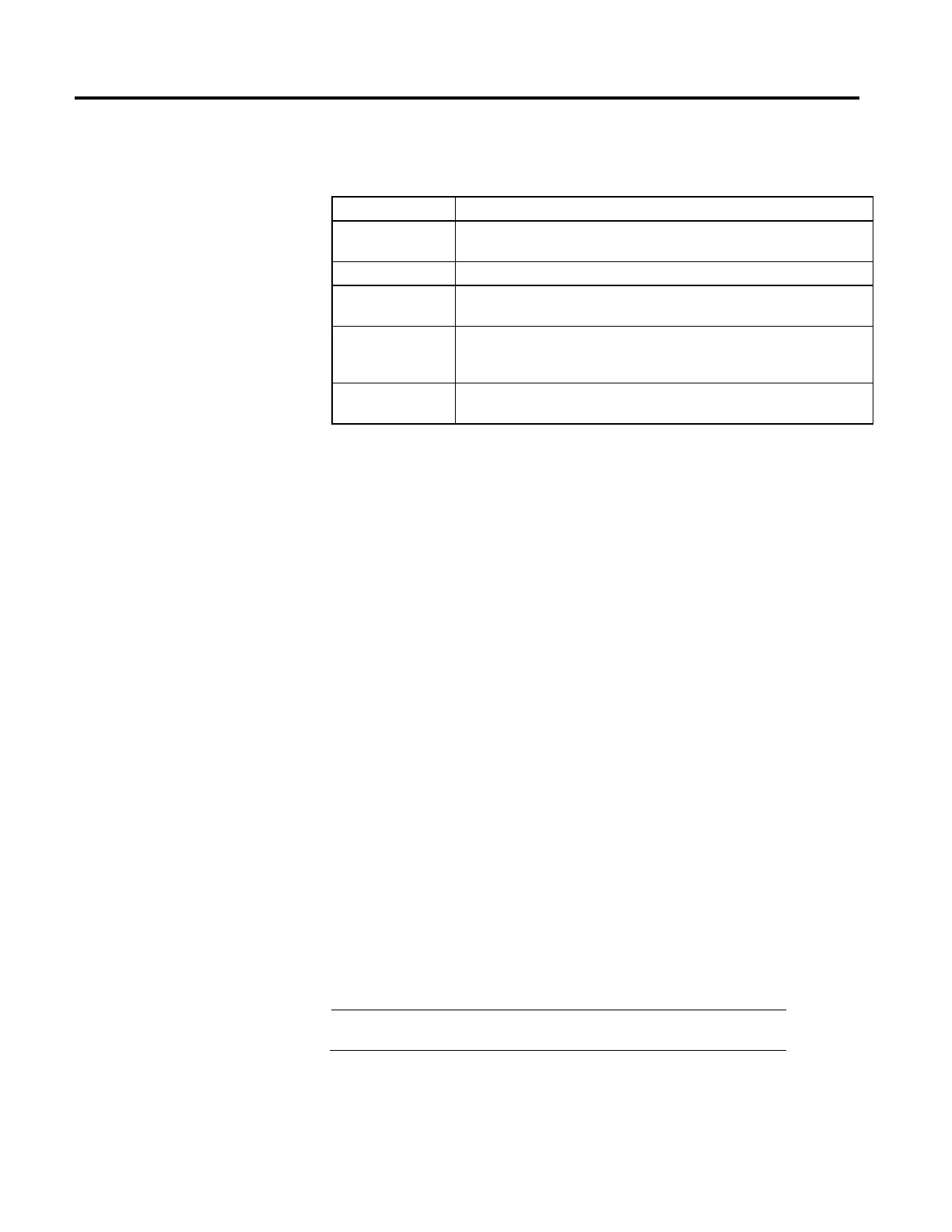

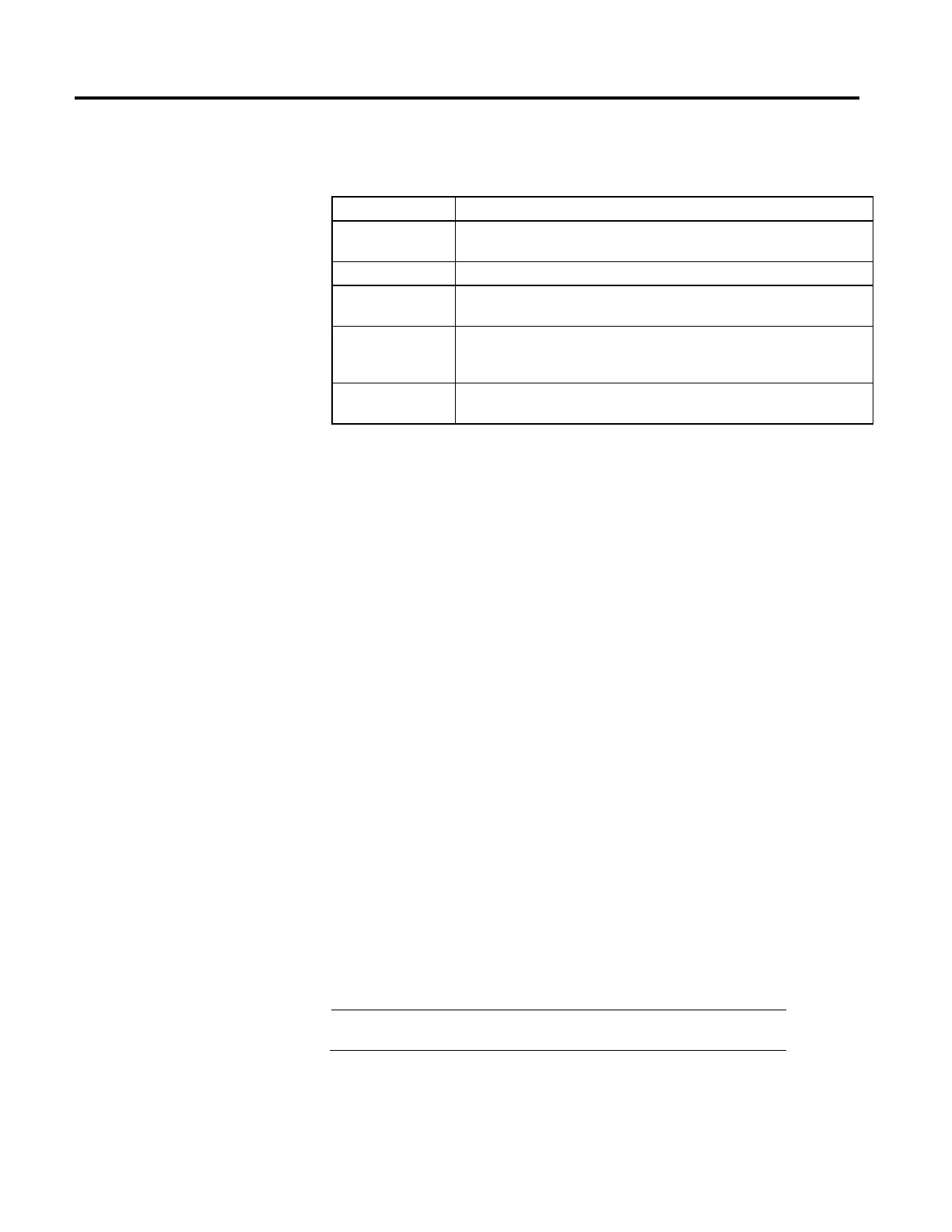

MOTION_INSTRUCTION Structure

Mnemonic Description

.EN (Enable) Bit 31 It is set to true when the rung makes a false-to-true transition and remains set to true until the

servo message transaction is completed and the rung goes false.

.DN (Done) Bit 29 It is set to true when the axis watch event checking has been successfully armed.

.ER (Error) Bit 28 It is set to true to indicate that the instruction detected an error, such as if you specified an

unconfigured axis.

.IP (In Process) Bit 26 It is set to true on positive rung transition and cleared to false after the watch event has

occurred, or has been superseded by another Motion Arm Watch, or terminated by a Motion

Disarm Watch command.

.PC (Process Complete) Bit

27

It is set to true when a watch event occurs.

Description

The MAW instruction sets up a Watch Position event to occur when the specified

physical axis reaches the specified Set-point position.

Set Point Position

Watch Position events are useful for synchronizing an operation to a specified axis

position while the axis is moving, such as activating a solenoid to push a carton off

a conveyor at a certain axis position. Select or enter the desired physical axis, the

desired Trigger Condition, and enter a value or tag variable for the desired Watch

Position.

If the targeted axis does not appear in the list of available axes, the axis has not

been configured for operation. Use the Tag Editor to create and configure a new

axis.

When an Arm Watch Position instruction is executed, the WatchEventStatus bit

is set to 0 (FALSE) and the actual position of a physical axis is monitored (at the

servo loop update rate) until it reaches the specified Watch Position. After the

watch position event occurs, the WatchEventStatus bit for the axis is set to 1

(TRUE).

Multiple watch position events may be active at a given time, however only one

may be active at a time for any given physical axis. Each event is monitored

independently and may be checked using the appropriate WatchEventStatus bit.

Important:

In large I/O connections, force values can slow down the rate at which the

controller processes repetitive watch positions.

Loading...

Loading...