Multi-Axis Coordinated Motion Instructions

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 375

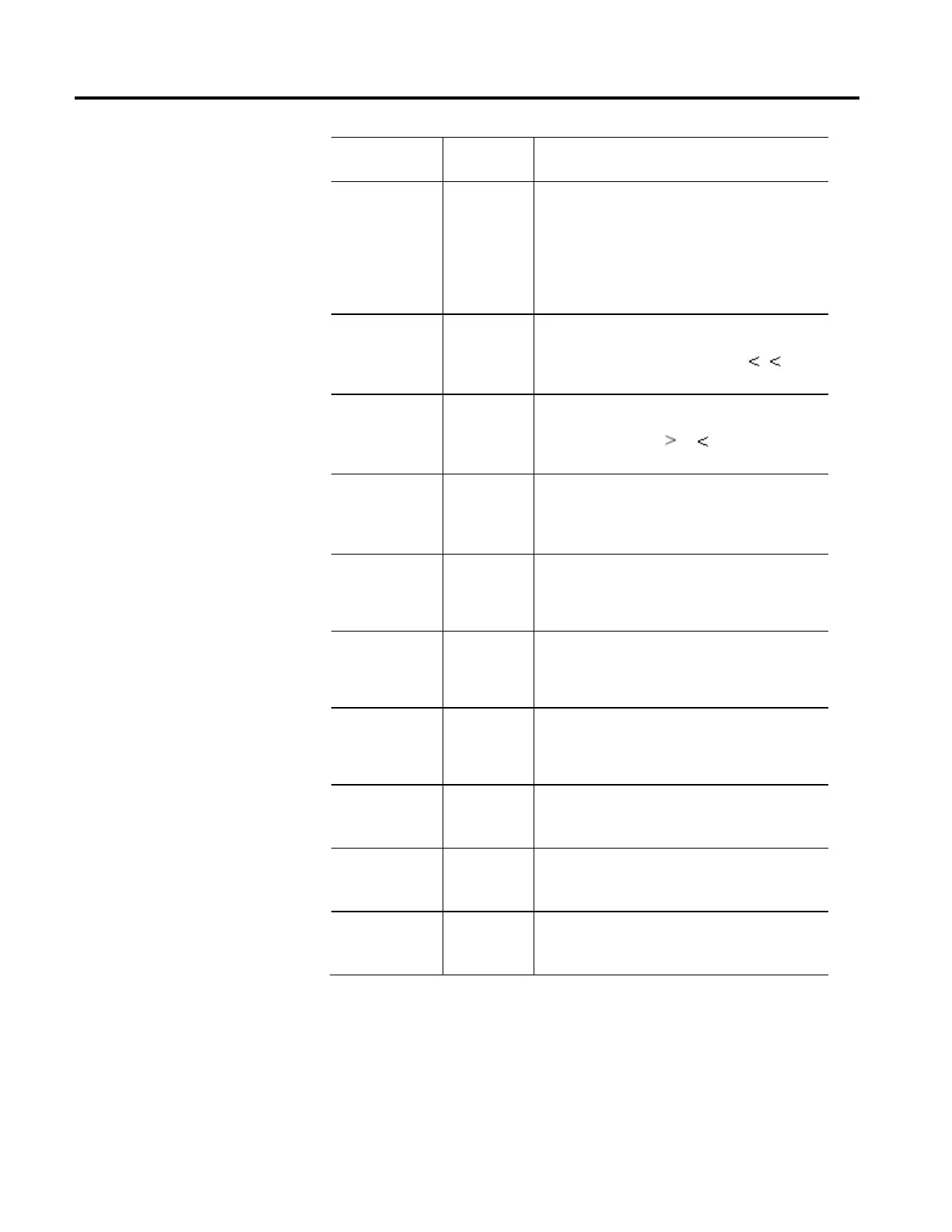

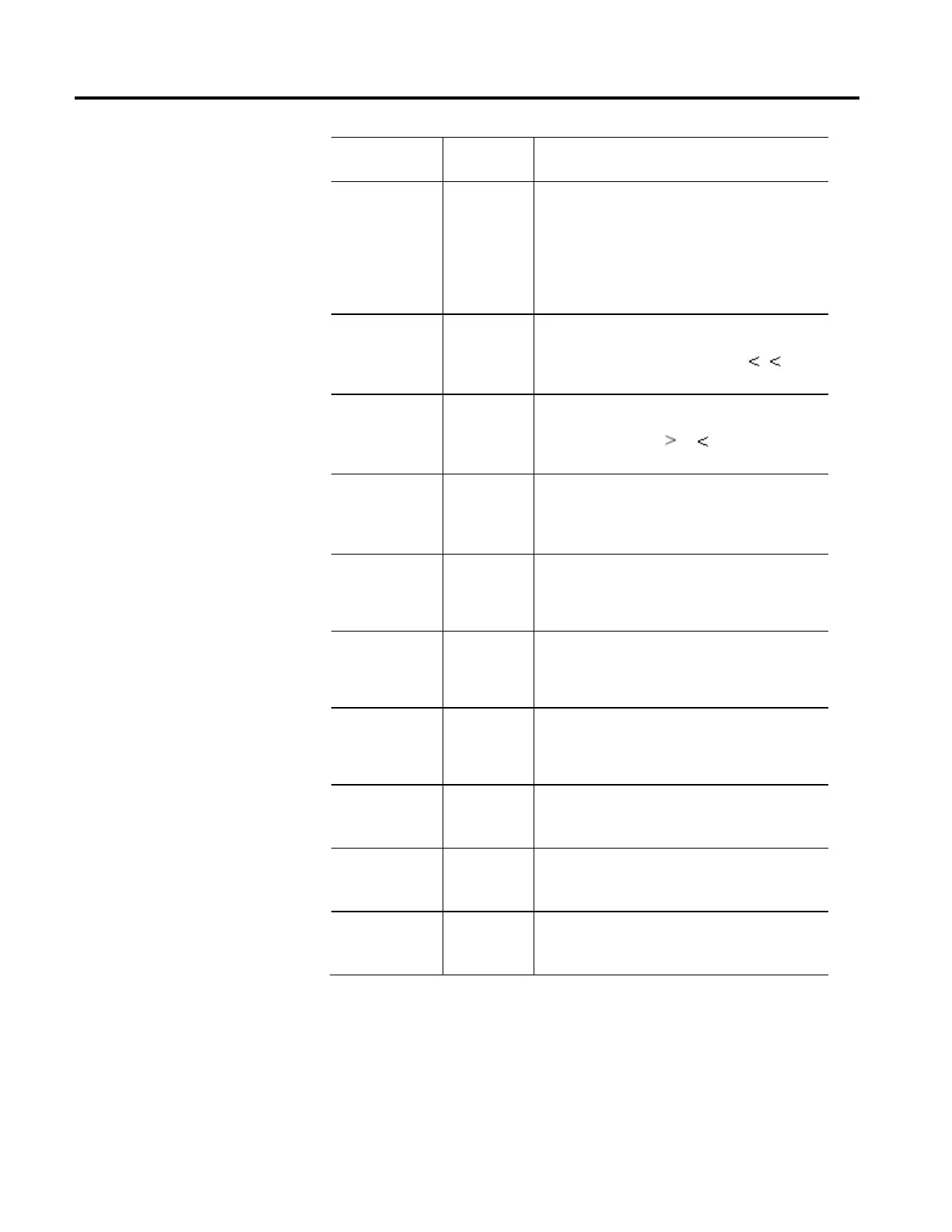

Error

Code

EX_ERROR

Code

Description

149 3-5 Orientation Axis Not Virtual

Extended error code 3 : Rx axis must be virtual if transforms are

enabled.

Extended error code 4 : Ry axis must be virtual if transforms are

enabled.

Extended error code 5 : Rz axis must be virtual if transforms are

enabled.

151 4 Joint Angle Beyond Limits

This indicates the error condition when the Joint 4 in a 5 axis Delta

goes beyond turns counter range limit (45899.99

J4 -45900)

Ext Error 4 : Joint J4 Beyond Limit

151 5 Joint Angle Beyond Limits

This indicates error condition when the Joint 5 in a 5 axis Delta

goes beyond +/-179, +179

J5 -179

Ext Error 5 : Joint J5 Beyond Limit

151 6 Joint Angle Beyond Limits

This indicates the error condition when the Joint 6 in a 4 axis Delta

goes beyond turns counter range limit (45899.99<J6<-45900)

Ext Error 6 : Joint J6 Beyond Limit

152 1 Maximum Orientation Speed Exceed for Rx

When Orientation axis Rx is commanded to move by an angle

greater than or equal to 180 degrees in one coarse update period,

this error and extended error will be returned.

152 2 Maximum Orientation Speed Exceed for Ry

When Orientation axis Ry is commanded to move by an angle

greater than or equal to 180 degrees in one coarse update period,

this error and extended error will be returned.

152 3 Maximum Orientation Speed Exceed for Rz

When Orientation axis Rz is commanded to move by an angle

greater than or equal to 180 degrees in one coarse update period,

this error and extended error will be returned.

153 1 Invalid Translation Position

MOP Invalid X Translation

Translation on X axis is Invalid

153 2 Invalid Translation Position

MOP Invalid Y Translation

Translation on Y axis is Invalid

153 3 Invalid Translation Position

MOP Invalid Z Translation

Translation on Z axis is Invalid

Example

The following examples activate the transformations between Cartesian

coordinate system CS1 and robot coordinate system CS2, which is a Delta 5 axis

geometry. In the first example, neither work frame nor tool frame are specified, so

Cartesian positions are computed at robot end-of-arm (EOA), with respect to the

robot base frame.

Loading...

Loading...