Motion Error Codes, faults, and attributes

558 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

11 At least one axis is not configured to a physical motion module or has not been

assigned to a Motion Group.

Axis Not Configured

For single axis instructions:

the Extended Error code for MAG, MDAC, MAPC, MAM, MAJ, MATC, and MCD is

defined as:

1 = Slave axis

2 = Master Axis

For the MAM, MCD, and MAJ instructions in time driven mode, the axis being

moved is a slave axis.

For multi-axes instructions:

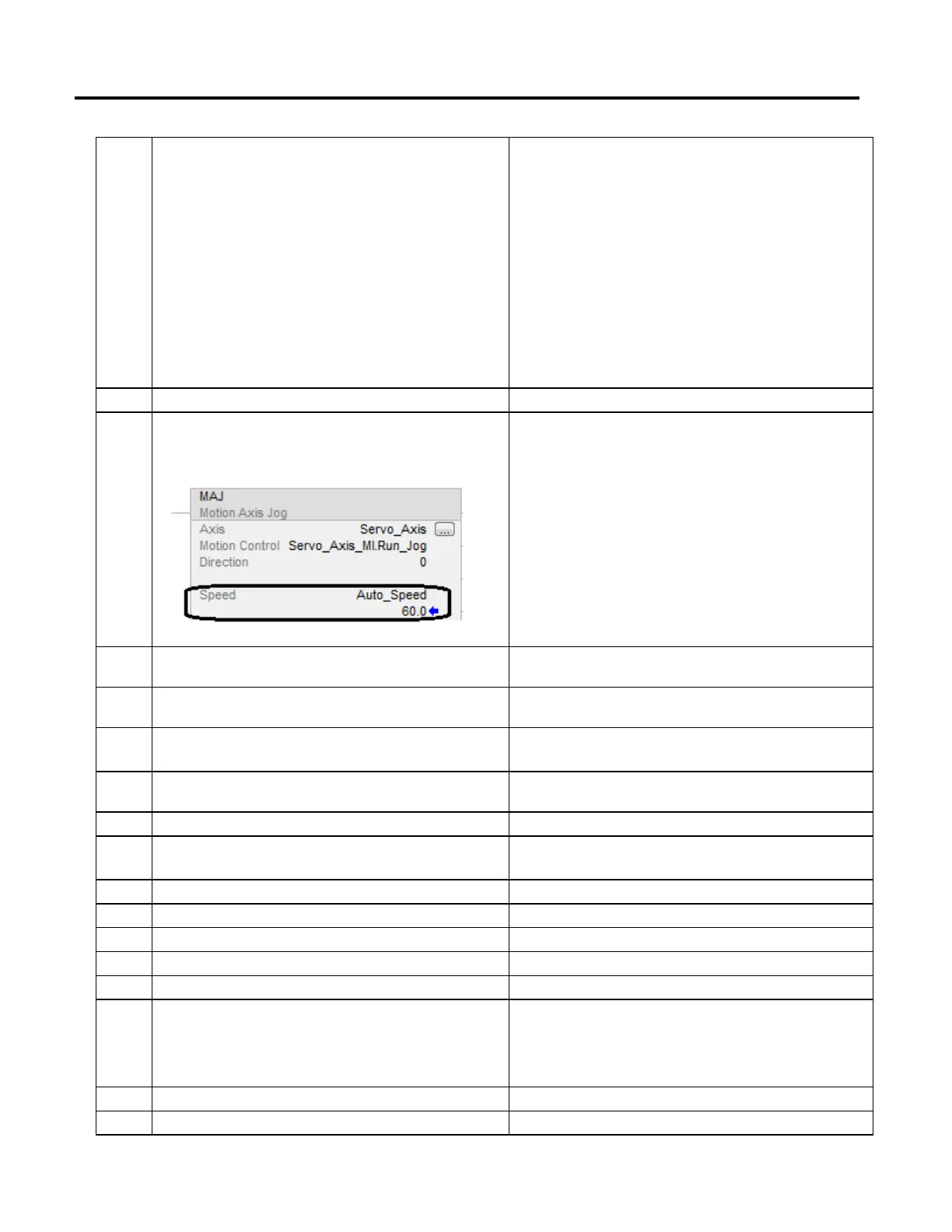

the Extended Error code for MDCC, MCLM, MCCM, MCCD, and MCPM is defined as:

The axis number in the coordinate system where

0 = 1st axis

2 = Master Axis or 3rd Slave Axis

12 Messaging to the servo module failed. Servo Message Failure

13 Refer to the online help for the instruction for extended error code definitions.

Example: An MAJ instruction has an ERR = 13 and an EXERR = 3. In this case,

change the speed so that it’s in range.

Parameter Out Of Range

An EXERR = 0 means the first operand of the instruction is outside its range.

14 The instruction cannot apply the tuning parameters because of an error in the

run tuning instruction.

Tune Process Error

15 The instruction cannot apply the diagnostic parameters because of an error in the

run diagnostic test instruction.

Test Process Error

16 Wait until the homing process is done.

For coordinated move instructions, it identifies which axis caused the error.

Home In Process Error

17 The instruction tried to execute a rotary move on an axis that is not configured

for rotary operation.

Axis Mode Not Rotary

18 The axis type is configured as unused. Axis Type Unused

19 The motion group is not in the synchronized state. This could be caused by a

missing or misconfigured servo module.

Group Not Synchronized

Group sync status is only cleared on a group overlap or CST loss fault.

20 The axis is in the faulted state. Axis In Faulted State

21 The group is in the faulted state. Group In Faulted State

22 Stop the axis before you execute this instruction. Axis In Motion

23 An instruction attempted an illegal change of dynamics. Illegal Dynamic Change

24 Take the controller out of test mode. Illegal Controller Mode

25 Either one of these could be the reason for the error:

1. If the number of axis in the coordinate system is not equal to 2 and MCCM is

programmed for Circle Type ‘Radius’.

2. If the axis used in the instruction is configured in Torque control mode.

Illegal Instruction

26 The cam array is of an illegal length. Illegal Cam Length

27 The cam profile array is of an illegal length. Illegal Cam Profile Length

Loading...

Loading...