American Eagle

®

30P Compressor Manual | Page 3

Chapter 2 - Installation

Component Installation

This section pertains to the installation of the air compressor, PTO, pump and other related

items. The instructions are intended as a guide to assist you with particular installation.

These instructions will provide only general information.

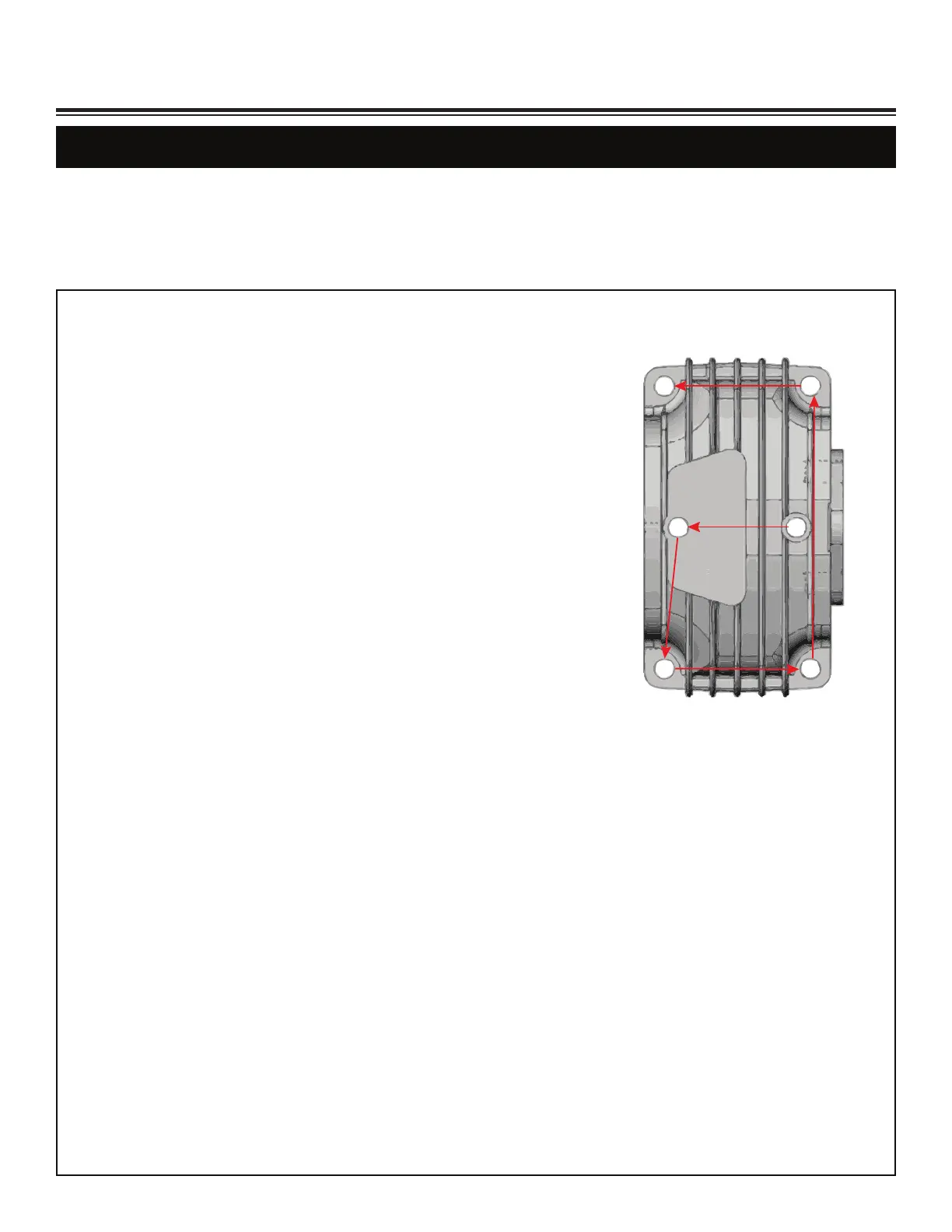

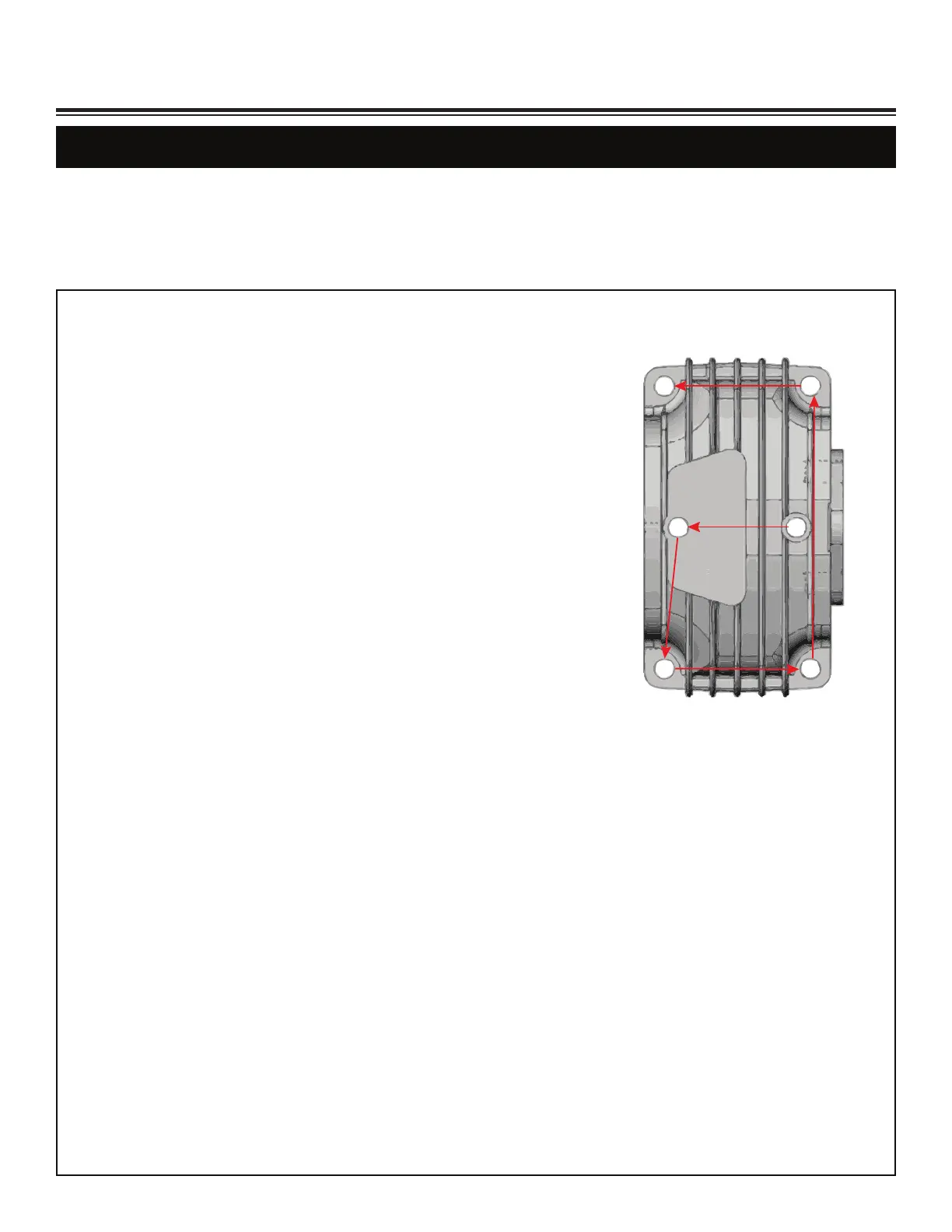

Compressor Torque Procedure

Head Assembly:

Torque Value: 34 ft-lbs

Procedure: Assemble head on the cylinder with head bolts

started only, not tight. Working in the pattern shown, torque

three times, increasing the torque each time as follows:

First Torque: 10 ft-lbs

Second Torque: 20 ft-lbs

Third Torque: 34 ft-lbs

After five hours of use re-torque bolts to 34 ft-lbs.

Cylinder Assembly:

Torque Value: 20 ft-lbs

Procedure: After assembling cylinder over pistons and setting into place, tighten (6) cap

screws finger tight. In a criss-cross pattern, tighten bolts evenly so all bolts are hand snug.

Again in a criss-cross pattern torque each bolt to 20 ft-lbs, checking each bolt twice. After

five hours of use, re-torque bolts to 20 ft-lbs.

Connecting Rod Control:

Torque Value: 18 ft-lbs

Procedure: Assemble rod onto the crankshaft taking care to align the machined surfaces

together and tighten cap screws finger tight. Tighten bolts until hand tight and torque to 18

ft-lbs. Check twice the torque reading before final assembly of the cylinders.

12

43

56

Loading...

Loading...