30 | 5000 Single-Point Moisture Analyzer

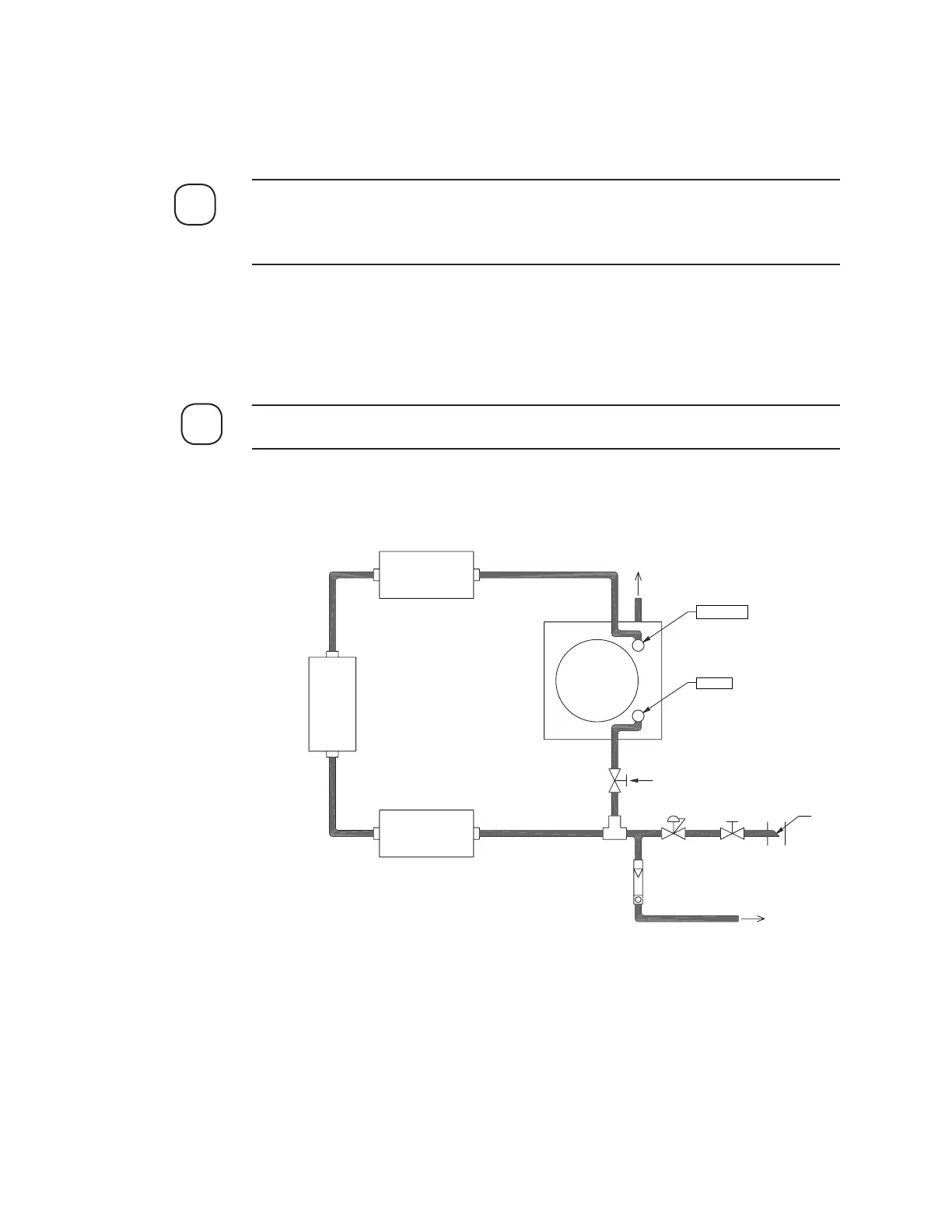

For some special applications, we recommend that the sample should also be run

through a contaminant trap and a super-activated dryer. Refer to the supplemental in-

formation supplied with the system to determine if these optional components are to be

used.

Moisture contamination of the dryer(s) can cause incorrect sample moisture data.

To prevent this contamination, never leave either end of a dryer open and exposed to

atmospheric moisture.

Conditioned sample gas used as reference

Configure sample system as shown in Figure 3-7a. Standard and optional conditioning

components (dryers, contaminant traps) should be strapped in the upright position to

support beams.

Dryer(s) must be vertical to avoid channeling (voids in the sieve).

NOTE

NOTE

VALVE

SHUTOFF

SAMPLE

TO VENT

REDUCER

PRESSURE

VALVE

SHUTOFF

SOURCE

SAMPLE

PROBE

(OPTIONAL)

FLOWMETER

BYPASS

AREA

APPROPRIATE

VENT TO

SAMPLE

REFERENCE

UNIT

FIELD

(OPTIONAL)

TRAP

CONTAMINANT

(<1 ppm)

SIEVE DRYER

MOLECULAR

(OPTIONAL)

MOLECULAR SIEVE DRYER

SUPER-ACTIVATED

TO VENT

AREA

APPROPRIATE

VENT TO

PROBE

SAMPLE

REFERENCE

SOURCE

SAMPLE

(OPTIONAL)

FLOWMETER

BYPASS

VALVE

SHUTOFF

REDUCER

PRESSURE

UNIT

FIELD

GAS SOURCE

REFERENCE

VALVE

SHUTOFF

REDUCER

PRESSURE

(OPTIONAL)

TRAP

CONTAMINANT

(OPTIONAL)

MOLECULAR SIEVE DRYER

SUPER-ACTIVATED

(<1 ppm)

SIEVE DRYER

MOLECULAR

Figure 8.

Sample system using conditioned

sample gas as reference.

Loading...

Loading...