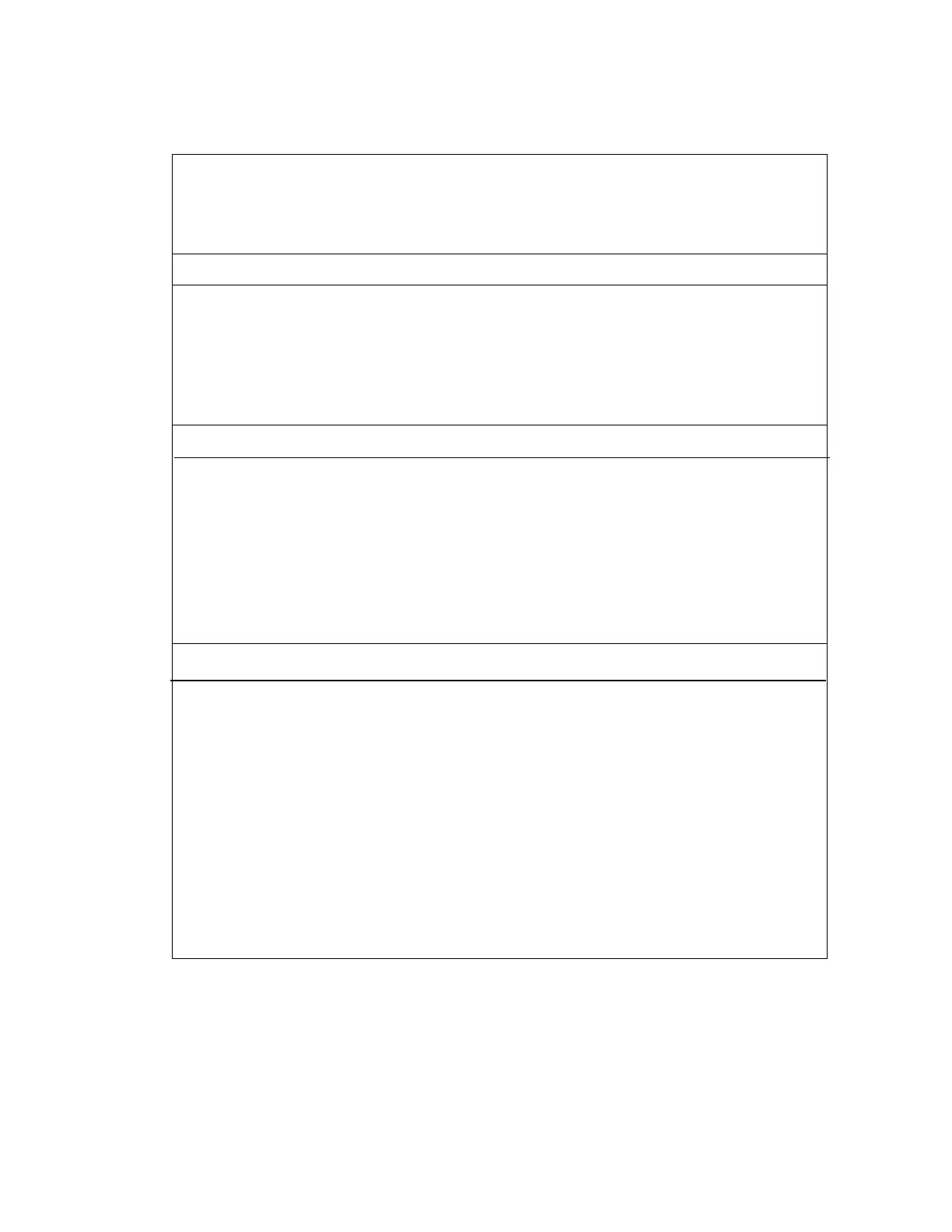

Troubleshooting Guide for 5000 Analyzer

Possible Cause Isolation Procedure Corrective Action

Field Unit LEDs do not light

Blown fuse F1 Replace F1.

Blown thermal cutoff S2 Replace S2

Faulty power supply Check for 24 VDC between red If voltage is not present and CB1 is

Fault connections and black test points TP2 (+) and TP1. closed, check power supply of T1 and

diodes CR4 and CR5.

Controller Alarms not operating

Incorrect operating parameters Check and secure all connectors between

boards. Check that all relays are secure.

Verify software parameters.

Faulty relay Perform Test Alarm Relays routine If relay works, place analyzer on-line. If

relay does not function, replace the CPU

board.

Faulty CPU board Replace CPU board.

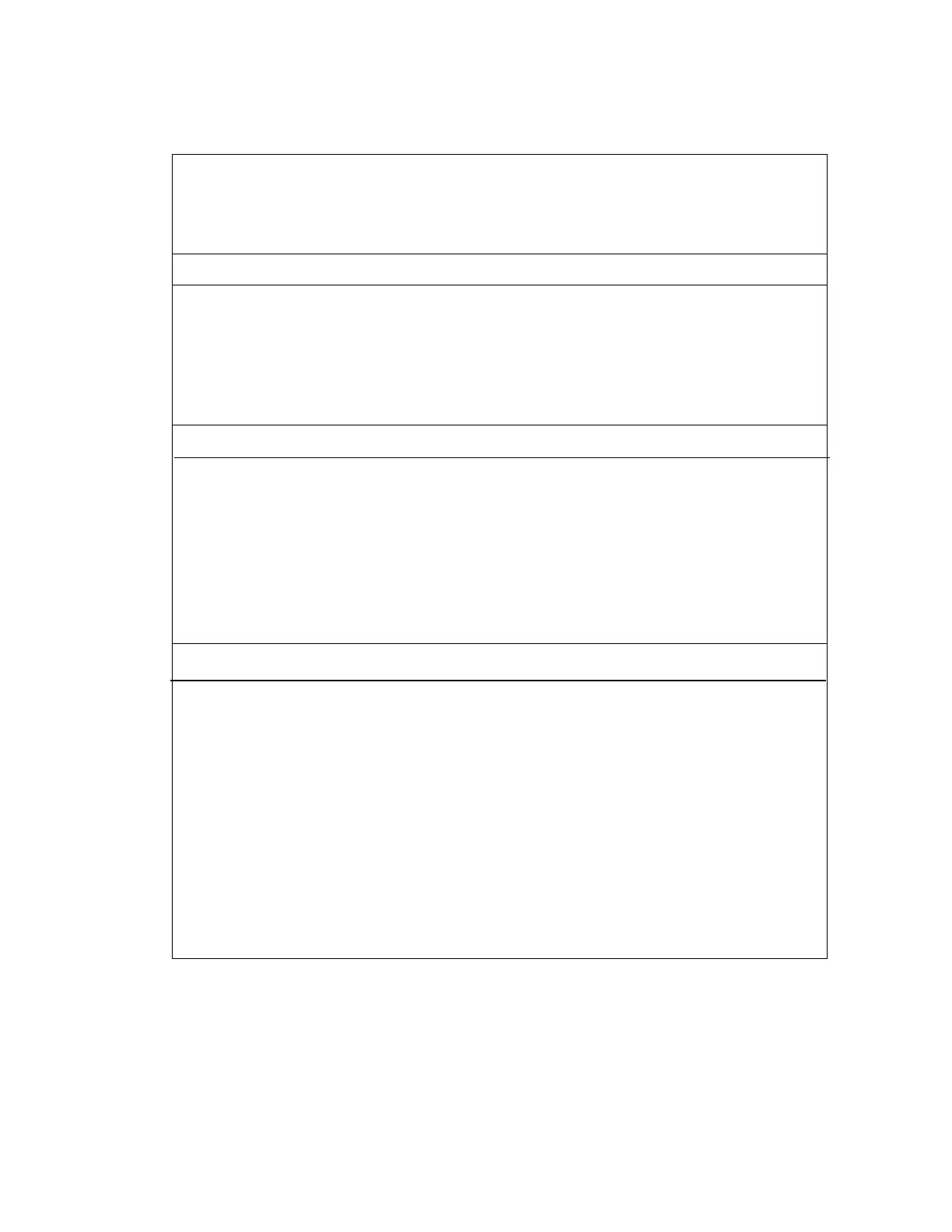

Display Reads Low in calibrate or operate modes

Incorrect operating parameters Check all values against Calibration

Data Sheet.

Incorrect back pressure Check, and if necessary, reset back

pressure.

Incorrect sample flow rate Check flow rate with Bubble-O-Meter Reset flow, if necessary.

Incorrect operating temperatures Check and, if necessary, set oven and

moisture generator operating temperatures.

Contaminated sample cell crystal Read cell frequency If cell frequency input is >3500 Hz, replace

the cell.

Contaminated dryer Substitute with known good Replace or re-activate dryer.

dryer.

Loading...

Loading...