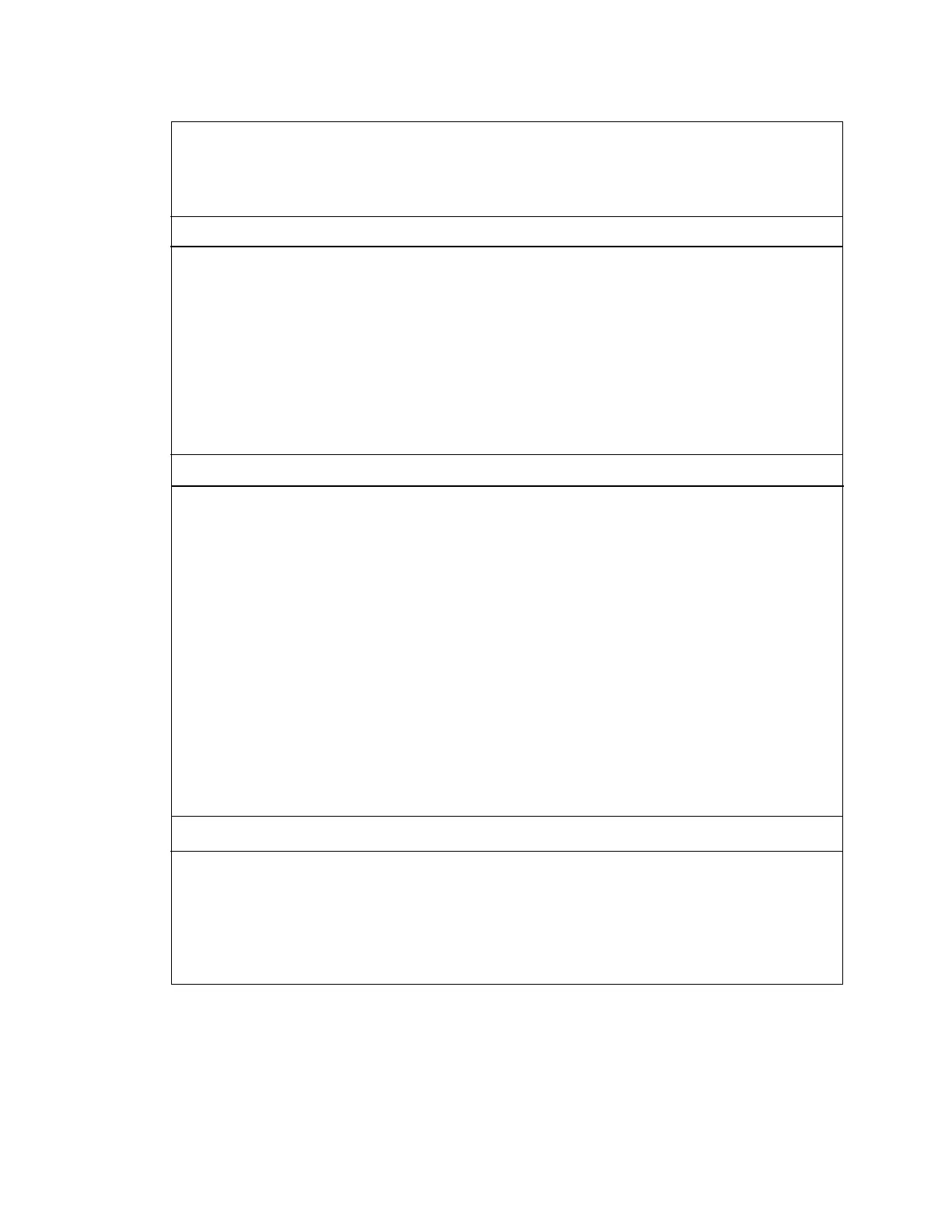

Essential Health & Safety Requirements | 41

Troubleshooting Guide for 5000 Analyzer

Possible Cause Isolation Procedure

Corrective Action

Analyzer Reads High

Incorrect flow rate Check, and if necessary, reset flow rate.

Incorrect back pressure Check, and if necessary, reset back

pressure.

Incorrect operating parameters

Check all values against Calibration

Data Sheet.

Leaks in sample tubing Correct leaks as necessary.

Low oven temperature Set oven temp to 60 °C ± 0.25 °C.

Moisture Generator Output Reading Incorrect

Incorrect flow rate or back pressure Check, and if necessary, reset flow rate

or back pressure.

Incorrect operating parameters Calibration has exceeded Max_Span Check all values against Calibration

and/or Max_Cal_Err limits. Data Sheet.

Incorrect calibration values entered Run display routine and check all values

against those listed on Calibration Data

Sheet. Re-enter values if necessary.

Recalculate Span values.

Dry moisture generator reservoir Check flow rates, generator temp- If reading are OK, check, and if

erature, and back pressure unit necessary, fill the reservoir.

board.

Incorrect moisture generator Measure temperature of moisture Adjust R26 on field unit board as

temperature generator J2 Pins 2 and 3 of field necessary to obtain 60 °C.

unit board.

Faulty reservoir tubing bundle Replace generator.

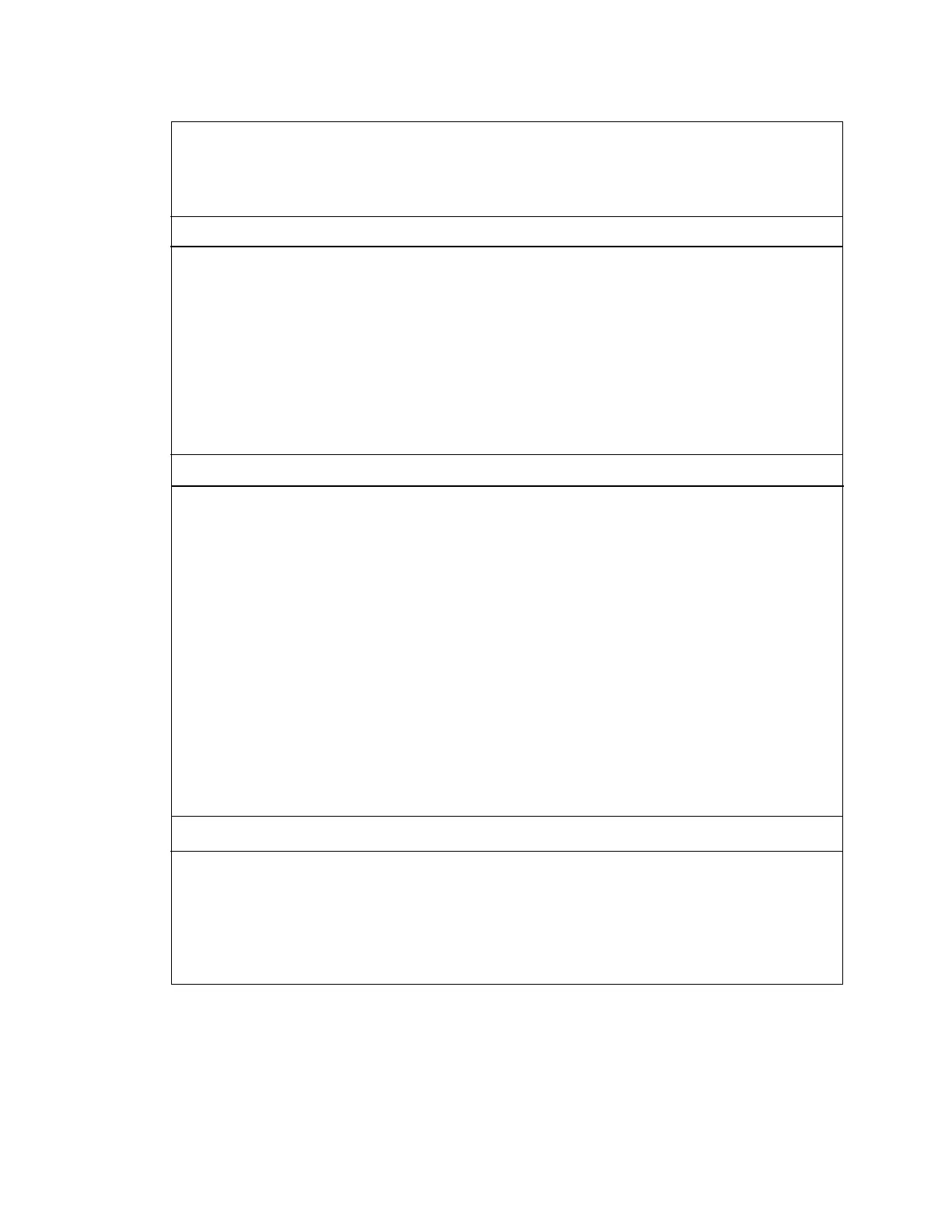

Cell_Temp_Alert

Environmental Temp Check for CR1 blinking Housing or ambient temperature is too

hot or too cold for the electronic control

amplifier to control cell temperature.

Faulty electronic control ampplifier Remove cell oven connector J1, If not, replace electronic control

CR1 will go on short pins 1 and 4 amplifier PCB.

together on the electronic control

amplifier PCB and CR1 will go off.

Loading...

Loading...