installation &

operating instructions

3750 Pulpress

Pressurisation unit

20

25.0 maintenance check

Regular check (Every 3 Months)

• Check the pump(s) are developing the correct pressure

and are not noisy or vibrating or air-locked.

• Check that the mechanical seal is not leaking.

• Check that the motor is not overheating.

• Checks at six monthly intervals

• Check electrical installation thoroughly for defects. En-

sure that the earth connections are making good contact.

• Check that the break tank is clean.

• Check the operation of the high and low pressure

set points.

• Check low level float switch, (high if fitted).

• Check vessel air charge

maintenance

For Maintenance Please contact our Service division on

service@armstrongfluidtechnology.com

Phone: +44(0)8444 145 145

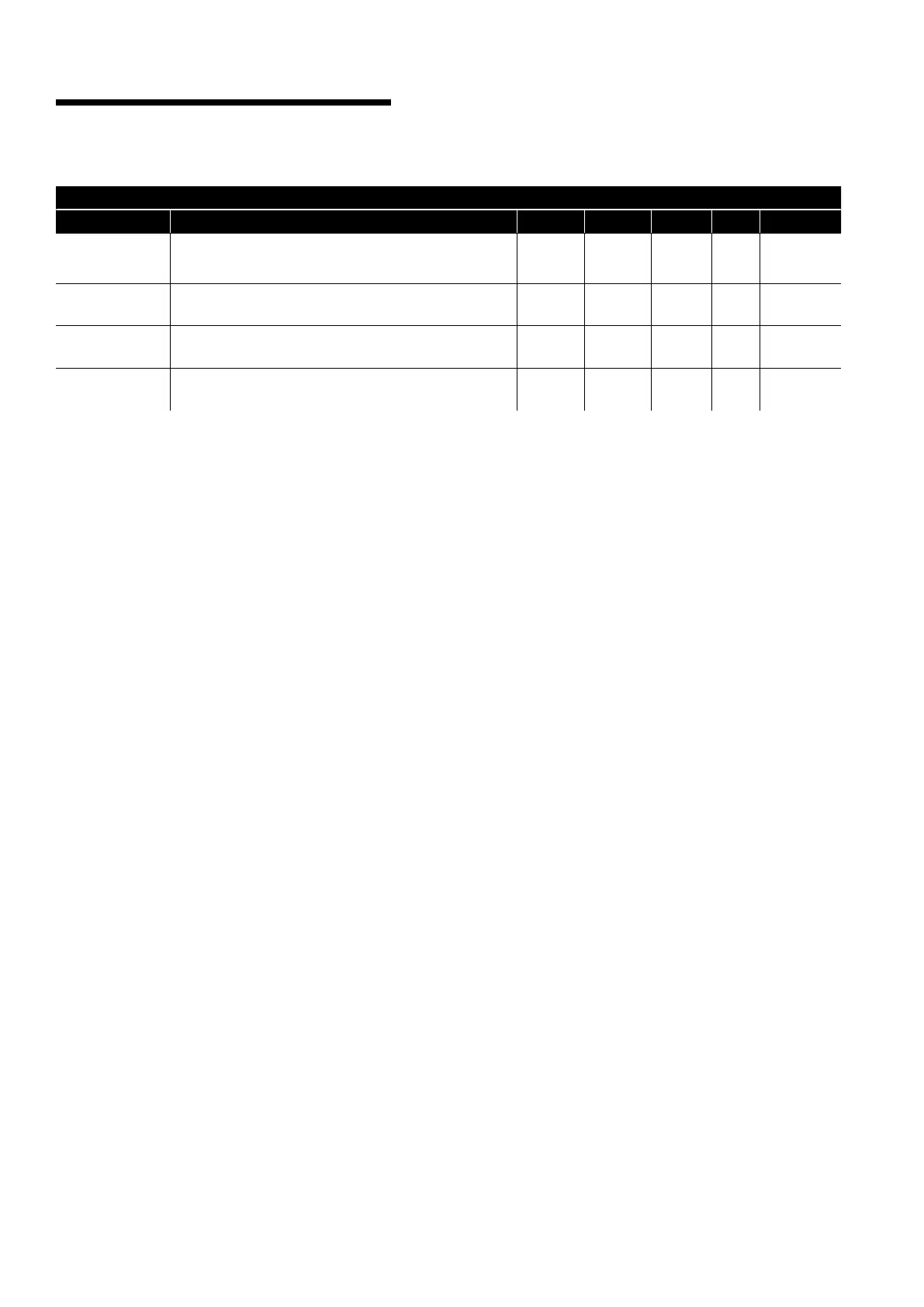

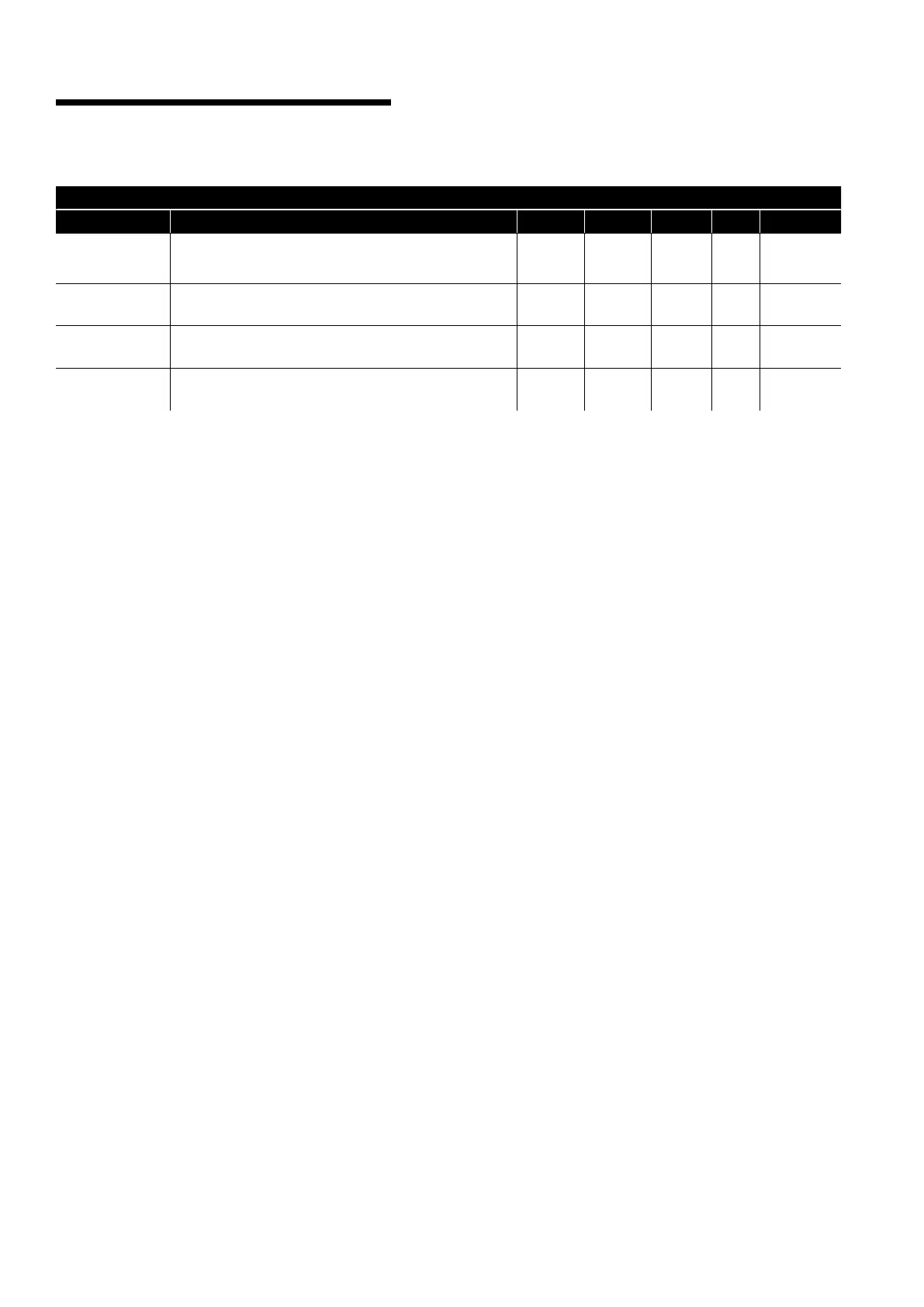

twin system alarms

alarm description priority blinking display pump stop reset

Service Reminder

Service Reminder(ser) - When Commissioned, date for service

reminder will be set. Armstrong service team can reset after

new.

17 Yes ser No only man

Device Oine - 2

Device 2 Oine - If the communication is lost between cPCO-

mini and cPCOe-2 expansion unit.

19 Yes 19 No only auto

Boiler Interlock - 1

Boiler Interlock 1 - If the pressure above or below the required

setpoint for system - 1

20 Yes BI1 Yes only auto

Boiler Interlock - 2

Boiler Interlock 2 - If the pressure above or below the required

setpoint for system - 2

21 Yes BI2 Yes only auto

Loading...

Loading...