installation &

operating instructions

3750 Pulpress

Pressurisation unit

21

26.0 fault finding chart

section problem

1 Pump(s) run continuously

2 Pump(s) will not run

3 High pressure

4 Low pressure

5 Low water level

26.1 pump(s) run continuously

symptom/cause action

Very high leakage rate

Check system for leaks. Check for split in

vessel bag via the air valve. Check non-

return valve is not bypassing through

second pump.

Faulty electrical circuit

Check that all wiring is in place and not lose

at any connections

System pressure

setting set too high

Compare system setting pressure (System

data on display nameplate). With Fill

pressure (pi) on data plate. To reset consult

Armstrong Service Dept.

Air lock

Check the pumps for presence of air and

ensure that the air is removed.

26.2 pump(s) will not run

symptom/cause action

Pump(s) tripped

Check miniature

Circuit breakers and Reset if necessary.

Faulty electrical circuit

Check that all wiring is in place and not

loose at any connections

Pump(s) burnt-out

seized

Repair or replace pumps.

Mode of operation

Check if the unit is enabled for bas control or

local control.

26.3 high pressure

symptom/cause action

Incorrect capacity of

vessel or larger system

than originally specified

Check system and vessel capacity by recal-

culating sizes.

Failure to maintain air

charge

Isolate and drain the vessel. Adjust the

air charge to match the fill pressure of the

system

26.4 low pressure

symptom/ cause action

Pump(s) tripped

Check miniature circuit breakers and reset

if necessary

Pump(s) burnt-out

seized

Repair or replace pumps

System leakage rate

very high

Check system for leaks. Check for split

vessel bag via the air valve. Check non-

return valve is not bypassing through

second pump

symptom/ cause action

No water in tank or

spasmodic water

supply

Ensure that incoming water supply is

functioning i.e. check isolating valve is open,

ballcock operates and water is clean

Delivery/suction

isolating valve closed

Open valves.

Suction strainer(s)

obstructed

Repair or replace strainers

Air lock

Check the pumps for presence of air and

ensure that the air is removed.

26.5 low water level

break tank

symptom/cause action

No water in break tank

or intermittent water

supply

Ensure that incoming water supply is func-

tioning (i.e. check isolating valve is open,

ballcock operates and water is clean).

Incoming water pres-

sure is not sucient

Increase the water pressure,

Consult Armstrong Service Dept.

alarm

symptom/cause action

Faulty electrical circuit

Check that all wiring is in place and not

loose at any connections

Broken or damaged

float switch

Replacement float switch required

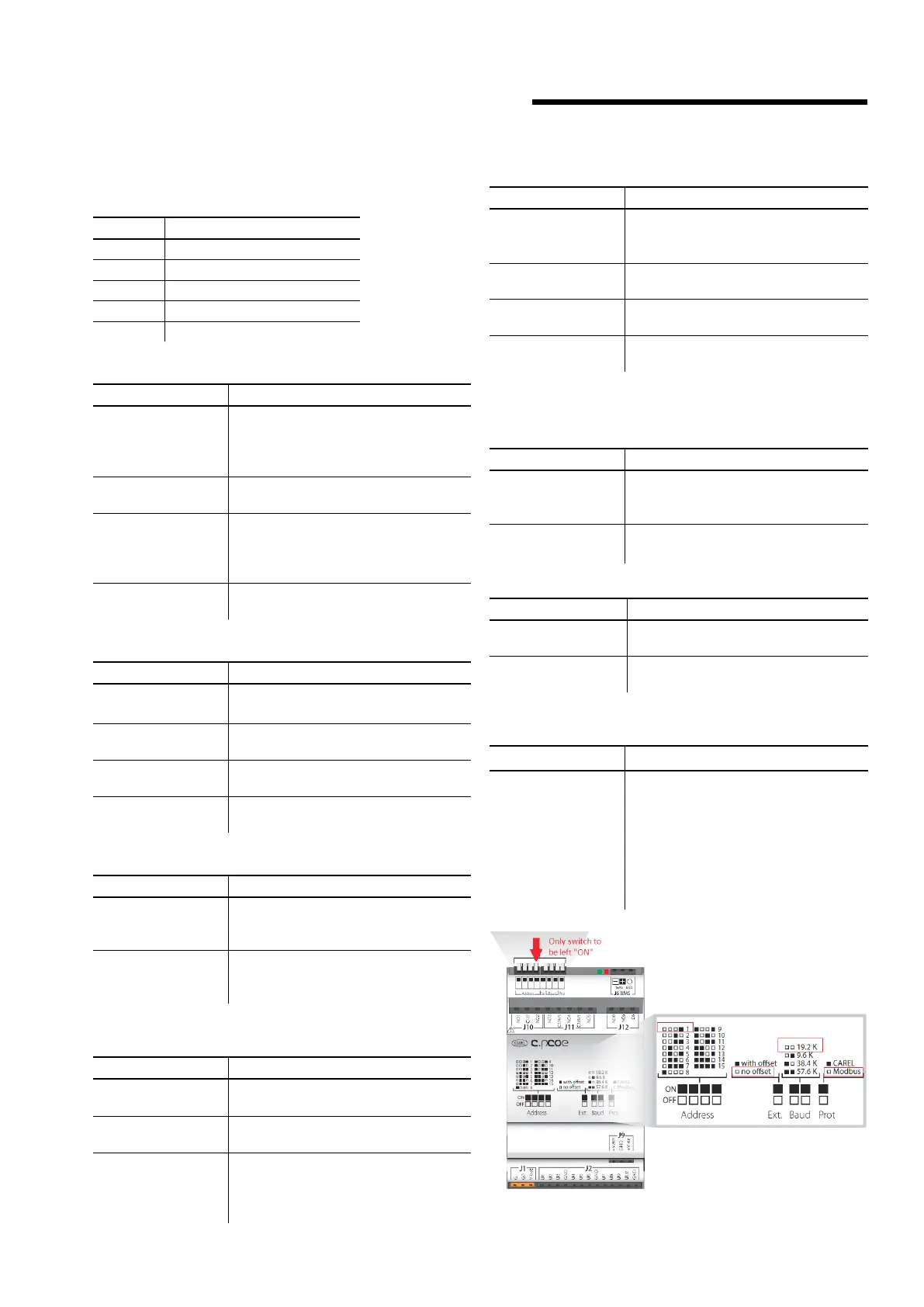

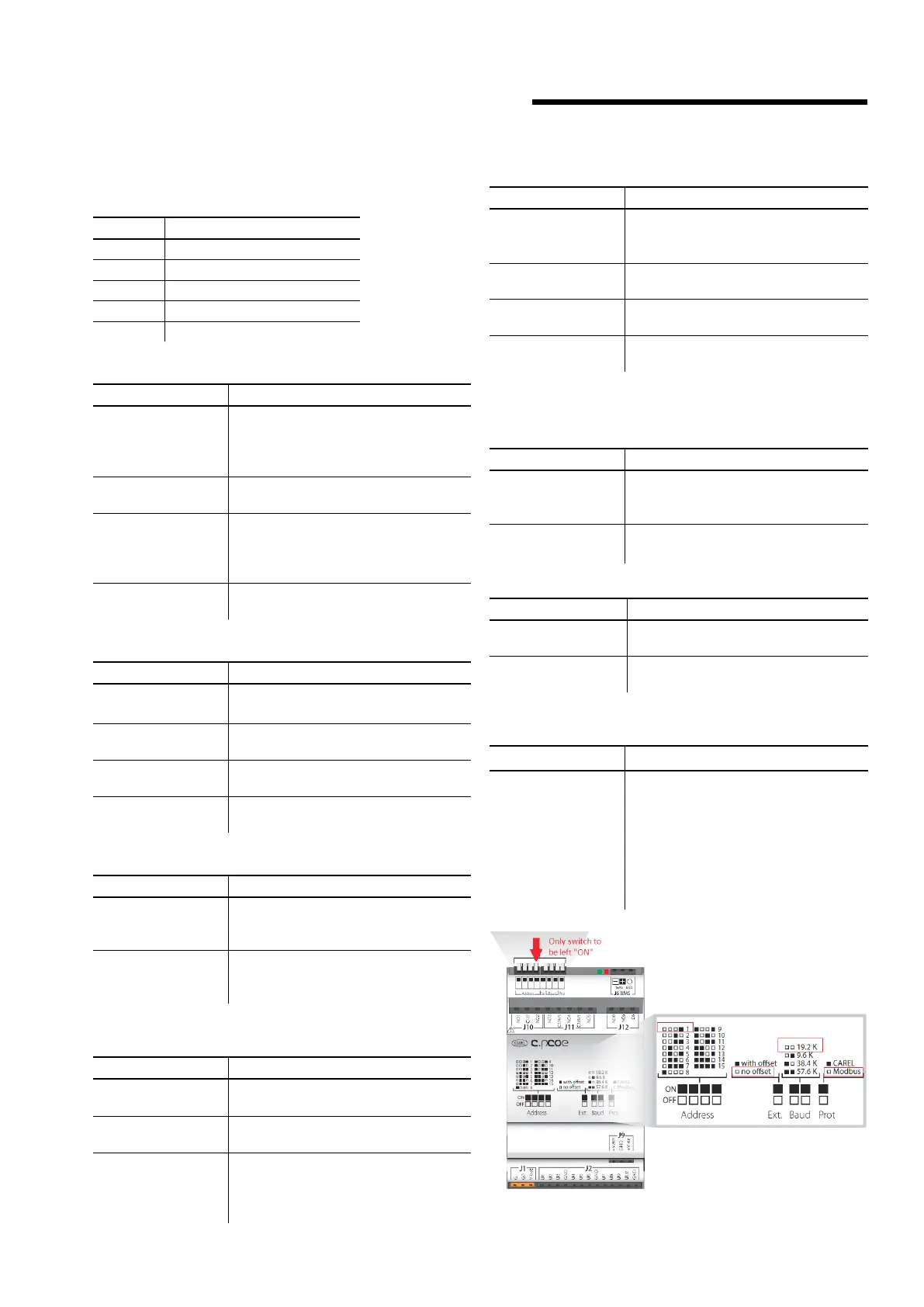

26.6 offline alarm _ cpcoe

symptom/cause action

c.pcoe loses connec-

tion to c.pco. mini

Check the wiring. All the dip switches

on c.pcoe under J10 port must be o

except the one highlighted in the below

picture

i.e. Address=1. For a twin-system unit

cpcoe-1 needs to have Address=1 and

cpcoe-2 needs to have Address=2.

Loading...

Loading...