installation &

operating instructions

3750 Pulpress

Pressurisation unit

4

1.0 ce conformities

lvd bs en 61010-1

Low voltage switchgear bs en 61439-1

Safety of machinery bs en iso 12100

Safety of machinery bs en 60204-1

Electromagnetic compatibility

Harmonic emissions bs en 61000-3-2

Electrostatic discharge bs en 61000-4-2

Radiated rf immunity bs en 61000-4-3

Fast transient bursts bs en 61000-4-4

Voltage surges bs en 61000-4-5

Conducted rf immunity bs en 61000-4-6

Voltage dips bs en 61000-4-11

Generic immunity bs en 61000-6-1

Generic immunity bs en 61000-6-2

Generic emissions bs en 61000-6-3

Generic emissions bs en 61000-6-4

Safety of stationary circulation bs en 60335-2-51

pumps for heating and service

water installation.

2.0 preface

1 The 3750 Pulpress pressurisation unit has been designed

for ease of setting and operation.

2 All packaged pump systems are pre-wired and fully tested

prior to dispatch.

3 If ordered with system criteria, all parameter data has

been entered into the controller in accordingly. Once

on-site connections have been made, and all pre-checks

carried out, the system is ready for commissioning.

4 During commissioning if system conditions are found to

vary from those set out in the design criteria, the parame-

ters can be easily changed.

3.0 introduction

1 This installation and operation manual contains specific

information regarding safe installation, operation and

maintenance of the

3750 Pulpress pressurisation unit.

These instructions must be read and understood by

anyone responsible for the installation and maintenance

of this equipment.

2 Prior to connect the unit to the power supply, it is

essential that all Pre-commissioning procedures are

carried out in full.

3 Operators and installers must familiarise themselves with

the operation and controls of the equipment.

4.0 warning symbols

Safety instruction where an electrical hazard is

involved.

Safety instruction where non-compliance would

aect safety.

Safety instruction relating to safe operation of the

equipment. (Attention)

5.0 safety instruction

1 This equipment has been designed for the pressurisation

of sealed heating, chilled water and closed condenser

water systems to the operating conditions shown.

2 This equipment should not be installed until operation and

maintenance instructions has been studied and under-

stood by the person(s) responsible.

3 Handling, transportation and installation of this equip-

ment shall only be undertaken with the use of appropriate

lifting gear.

4 The set shall not be used for any purpose other than that

for which it was designed and sized.

5 The set shall not be operated with the cover removed and

the cover interlocked isolator overridden.

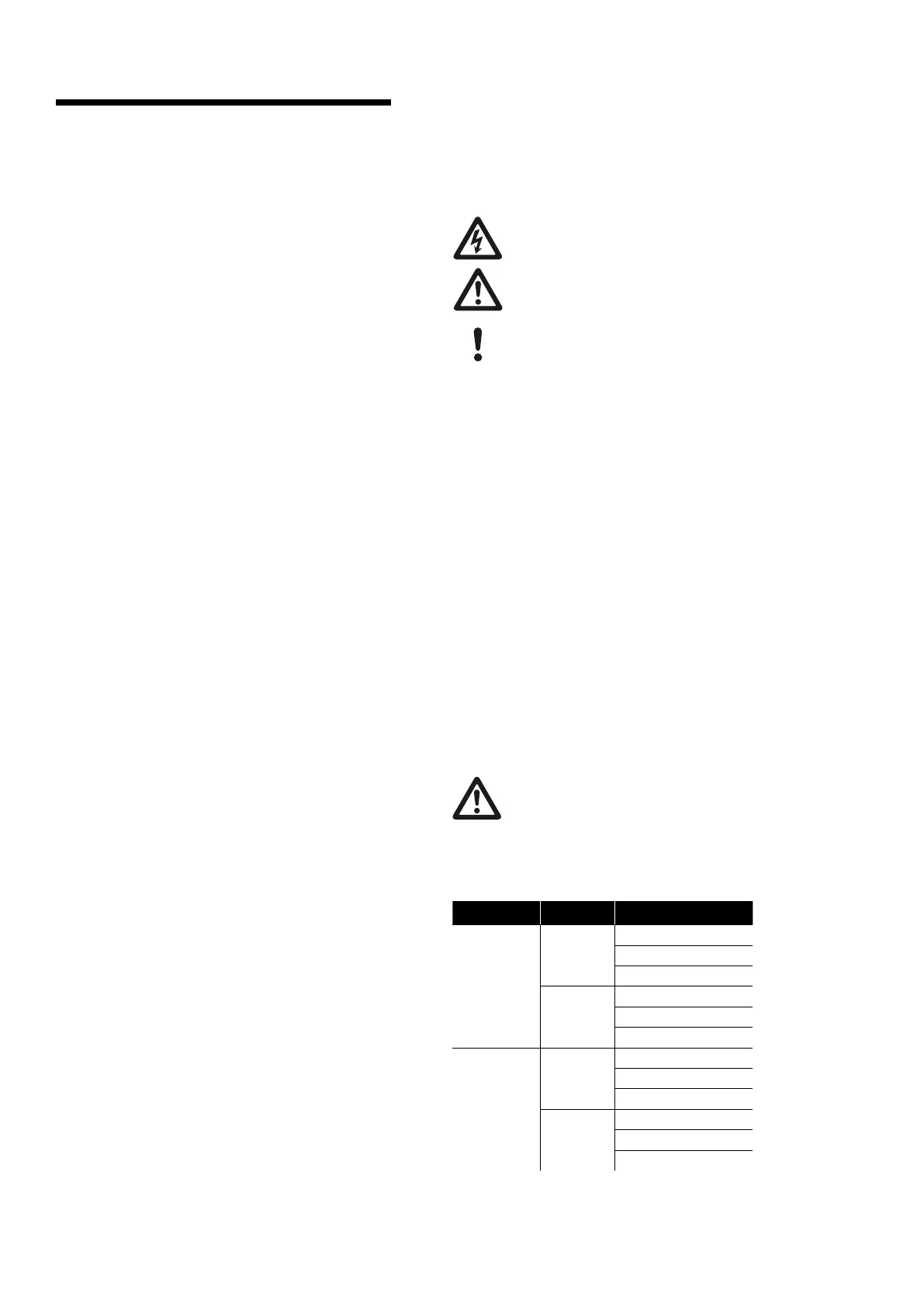

note

During normal operation, the pumps will only gen-

erate pressures sucient to satisfy system demand.

However, abnormal running conditions may cause

closed valve pressures to be experienced.

6.0 range definition

system(s) pump(s) pressure range

1 1 Low

Med

High

2 Low

Med

High

2 1 Low

Med

High

2 Low

Med

High

Low Pressure = 0.5-2.7 bar

Med Pressure =

0.5-5.5 bar

High Pressure =

0.5-8.0 bar

Loading...

Loading...