installation &

operating instructions

3750 Pulpress

Pressurisation unit

5

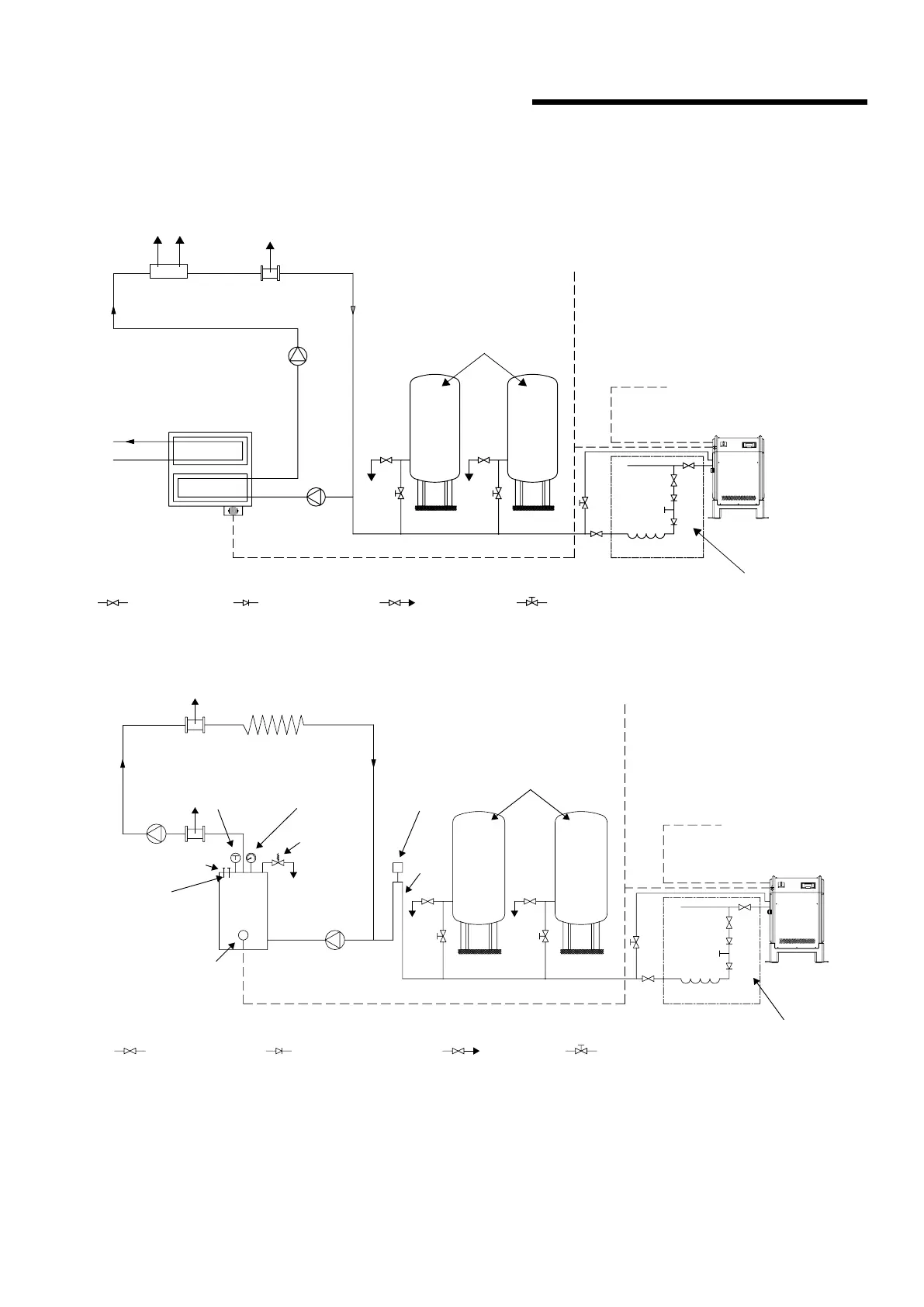

7.0 typical chilled water sealed system

expansion vessels

electrical safety interlock

isolating valve drain cock

lock shield valve

non-return valve

return

condenser

evaporator

pump

pump

chillier unit

flow

elecrical supply

3750 pulpress

signals to bms

cooling load

see leaflet on air eliminators

alternative

position

to cooling

tower

chillier

controls

mains

supply

test

point

system fill

connection

equipment within

this area is

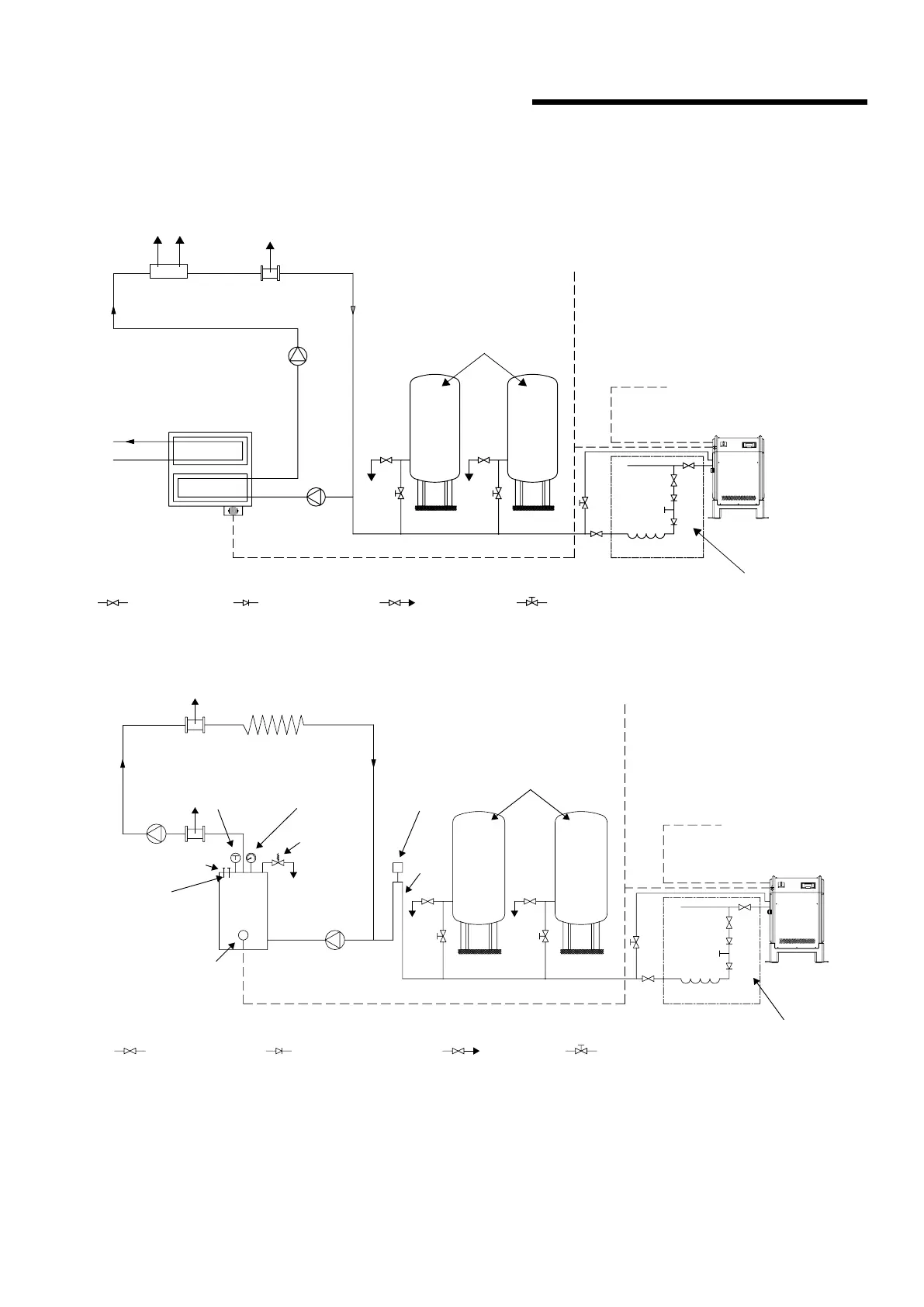

8.0 typical lthw sealed system- max. 100°c

see leaflet on air eliminators

elecrical supply

expansion vessels

return

flow

heating load

temperature

gauge

pressure

gauge

alternative

position

boiler

controls

over temperature

energy cutout

boiler

tat

auto-air

vent with

on-o clock

anti-

gravity

loop

safety

valve

signals to bms

3750 pulpress

electrical safety interlock

isolating valve drain cock

lock shield valve

non-return valve

equipment within

this area is

mains

supply

test

point

system fill

connection

pump

pump

Loading...

Loading...