installation &

operating instructions

Design Envelope 4300 & 4380

Vertical In-line Pumping Unit

11

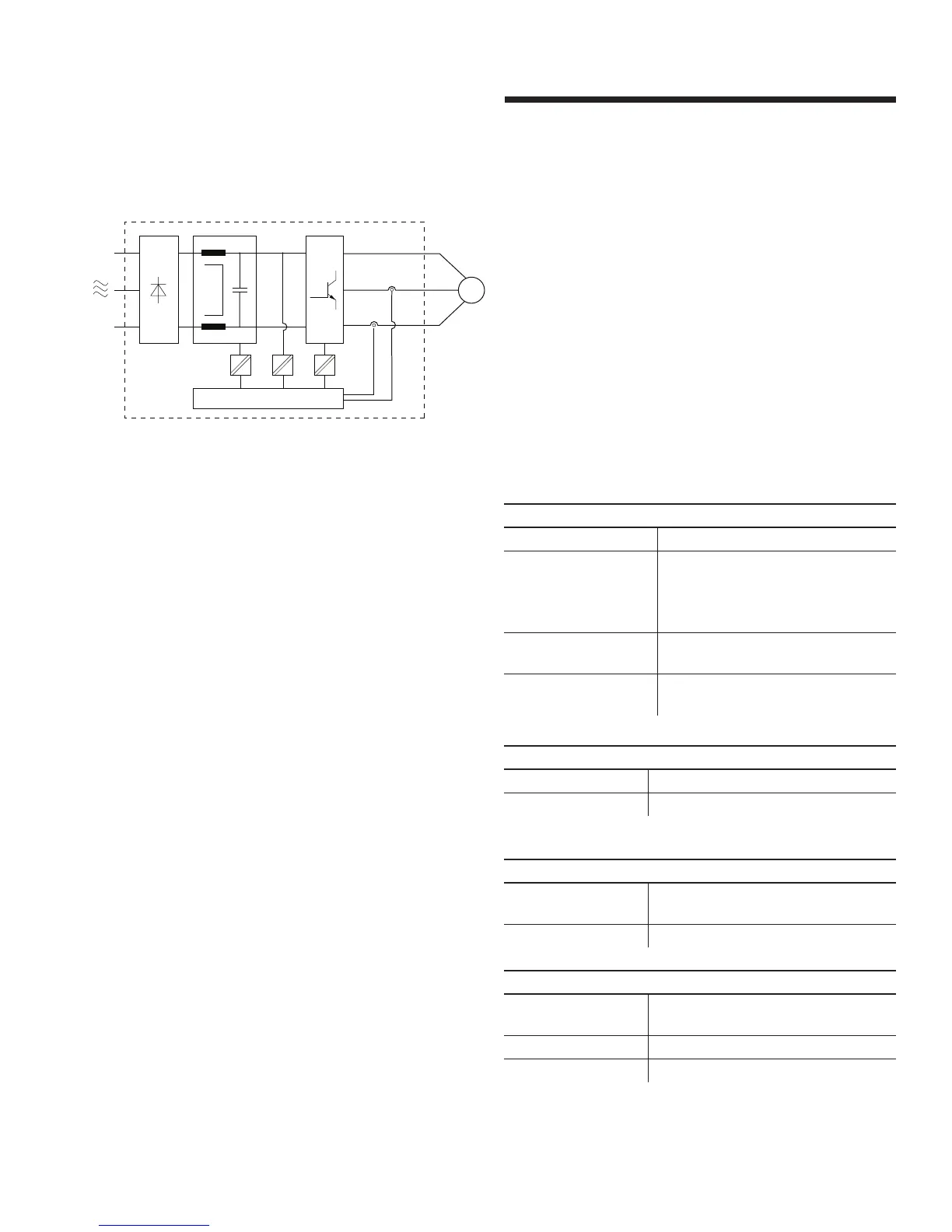

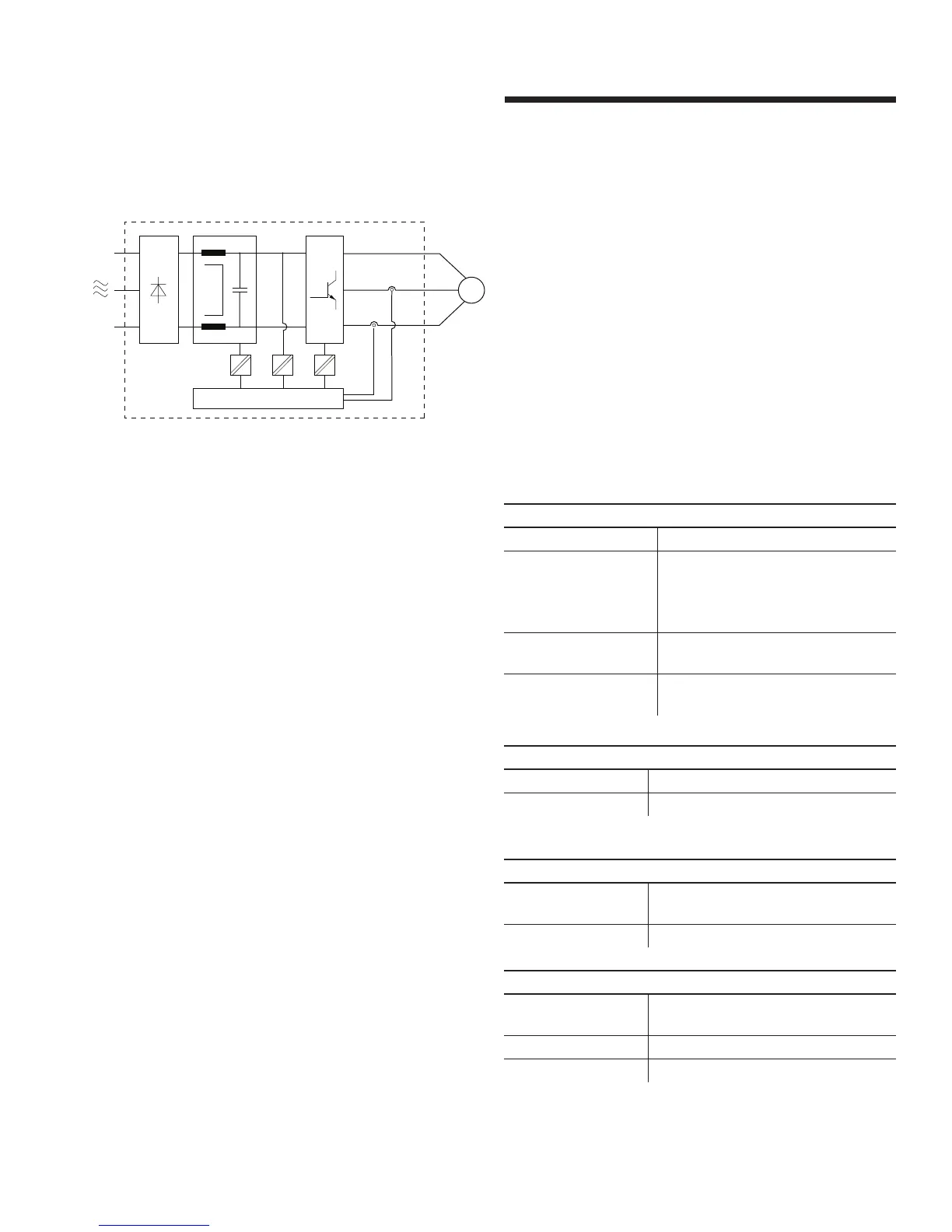

4 Current transducers (Hall Eect-Based Current Sensor).

31

4

2

M

2.1.4.3 earth leakage current

Earth leakage current is primarily caused by the capacitance

between motor phases and the motor frame. The rfi filter

contributes additional leakage current, as the filter circuit is

connected to earth through capacitors (Cy).

The size of the leakage current to the ground depends on the

following factors, in order of priority:

1 Switching pwm frequency

2 Motor grounded on site or not

The leakage current is of importance to safety during handling/

operation of the drive if (by mistake) the drive has not been

earthed.

2.1.4.4 over voltage protection

The voltage in the intermediate circuit is increased when the

motor acts as a generator. This occurs in two cases:

1 The load generates energy.

2 During deceleration (ramp-down) if the moment of inertia is

high, the load is low and the ramp-down time is too short for

the energy to be dissipated as a loss in the motor frequency

converter, the motor and the installation.

The drive turns o to protect the igbt transistors and the

intermediate circuit capacitors when a certain voltage level is

reached on DCbus.

2.1.4.5 mains supply interference/harmonics

A motor integral drive takes up a non-sinusoidal current from

mains. A non-sinusoidal current can be transformed by means

of a Fourier analysis and split up into sine wave currents with

dierent frequencies, i.e. dierent harmonic currents in with

50 Hz as the basic frequency.

Some of the harmonic currents might disturb communication

equipment connected to the same transformer or cause reso-

nance in connection with power-factor correction batteries.

To ensure low, harmonic currents, for the residential and com-

mercial environments, an optional harmonic filter is necessary.

2.2 electrical specification

Main supply (l1 l2 l3)

Supply frequency 48 - 62Hz

Supply voltage 1 × 200-230v ± 10%,

3 × 200-230v ± 10%,

3 × 380-480v ± 10%,

3 × 575-600v ± 10%

Max. imbalance of

supply voltage

± 2% of rated supply

Switching on

supply voltage

Once every 2 minutes

Output ratings

Output Current 100% Drive Rated Power continuously

Overload Capacity 150% for 60 secs

Digital inputs

Programmable

digital inputs

4

Voltage level 0-24Vdc (user selectable npn or pnp)

Pulse input

Programmable pulse

input

1

Voltage level 0:24Vdc

Max frequency 10kHz

Loading...

Loading...