installation &

operating instructions

Design Envelope 4300 & 4380

Vertical In-line Pumping Unit

26

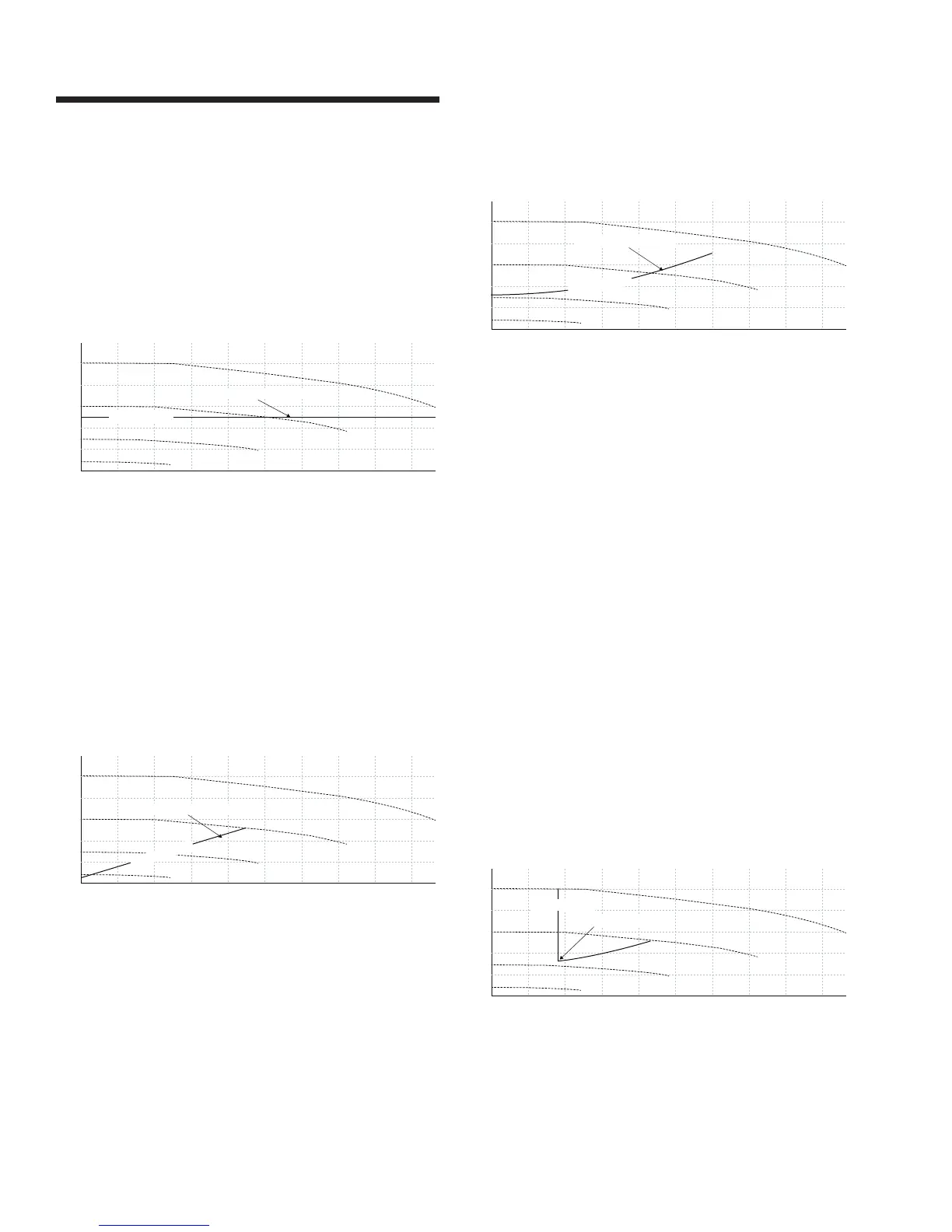

5.2 constant pressure

Design Envelope pumps can be configured to maintain a

constant pump head in a system as the demand varies. This

eectively simulates the mounting of a dierential pressure

sensor at, or near, the pump.

0

0

20 40 60 80 100

200

400

600

800

1000

1200

120 140 160 180

target curve

Constant Pressure Control Curve

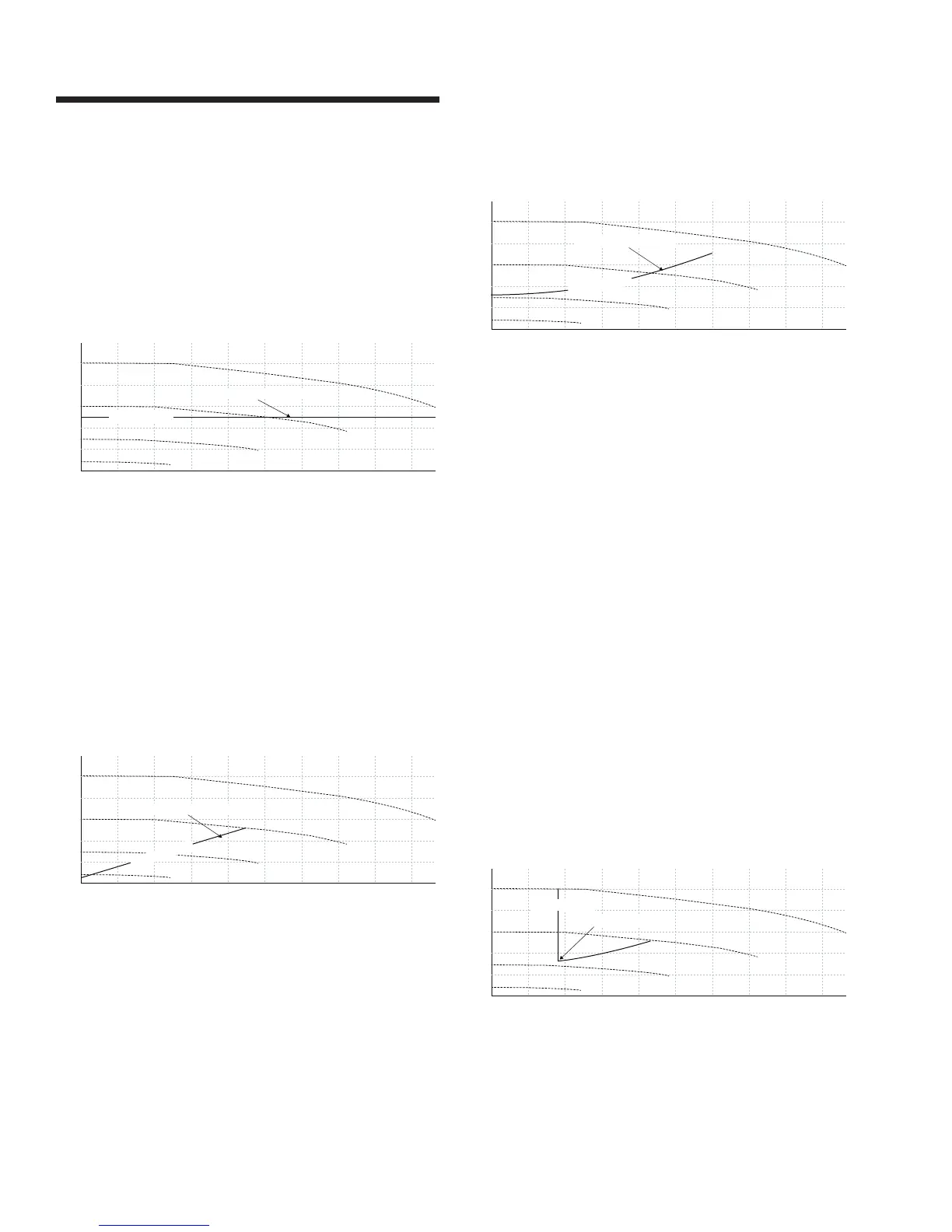

5.3 linear pressure

Linear Pressure Control is where the controller is set to control

the speed according to a control ‘curve’ between max and min

flow. This type of control will change the pump speed to ensure

the pump operates on the projected linear control curve, where

the pump head varies directly with the flow. This type of control

is well known globally and is eective as far as the straight lin-

ear line will allow. For more realistic hvac control with superior

energy savings, consider the following control recommendation

5.4 Quadratic Curve Control.

0

200

400

600

800

1000

1200

target curve

Linear Pressure Control Curve

5.4 quadratic curve control

Quadratic Pressure Control is where the controller is set to

control the speed according to a control curve between max

and min flow. It is widely recognised that fitting a dierential

pressure sensor at the most remote load, across the supply

piping and return piping encompassing the valve and coil set, is

the benchmark scheme for energy eciency.

Design Envelope pumps can replicate this control without the

need for the remote sensor. As the flow required by the system

is reduced, the pump automatically reduces the head devel-

oped according to the pre-set control curve.

0

0

20 40 60 80 100

200

400

600

800

1000

1200

120 140 160 180

target curve

Quadratic Control Curve

5.5 quadratic curve control with minimum

flow protection

This configuration is designed for hvac hydronic systems

where flow sensitive equipment required a minimum flow for

equipment stability; such as a chiller that cannot tolerate flow

below a certain volume. This control will take advantage of the

5.4 Quadratic Curve Control mode, where the pump will in-

crease speed to maintain a minimum flow setting as the system

load is shutting down.

Pump controls can only control the flow to the maximum speed

or motor limit;

5.5.1 A dry-contact relay is supplies which will close when

minimum flow is reached, which can be used for an

alarm or other device.

5.5.2 When ordered, a minimum flow breach can be con-

trolled by opening a customer supplied 2-way (normally

closed) system bypass valve. The valve will be opened

and closed as system flow, which is also monitored

by the controls, registers below or above the pre-set

(adjustable) minimum flow value, using the built-in

outputs and relays in the Design Envelope pumping unit

on-board controls.

0

0

20 40 60 80 100

200

400

600

800

1000

1200

120 140 160 180

target curve

Minimum Flow Setting

5.6 quadratic curve control with maximum

flow protection

This configuration is ideal for hvac hydronic systems where

pumps are generally oversized and a flow limit is required

for system equipment stability and resulting energy savings.

This control will take advantage of the 5.4 Quadratic Curve

Control mode, where the pump will decrease speed to maintain

Loading...

Loading...