installation &

operating instructions

Design Envelope 4300 & 4380

Vertical In-line Pumping Unit

7

column or install a ‘wae’ isolation pad under the pump. It is

critical that piping be installed in such a manner that the pump

does not become a pipe support.

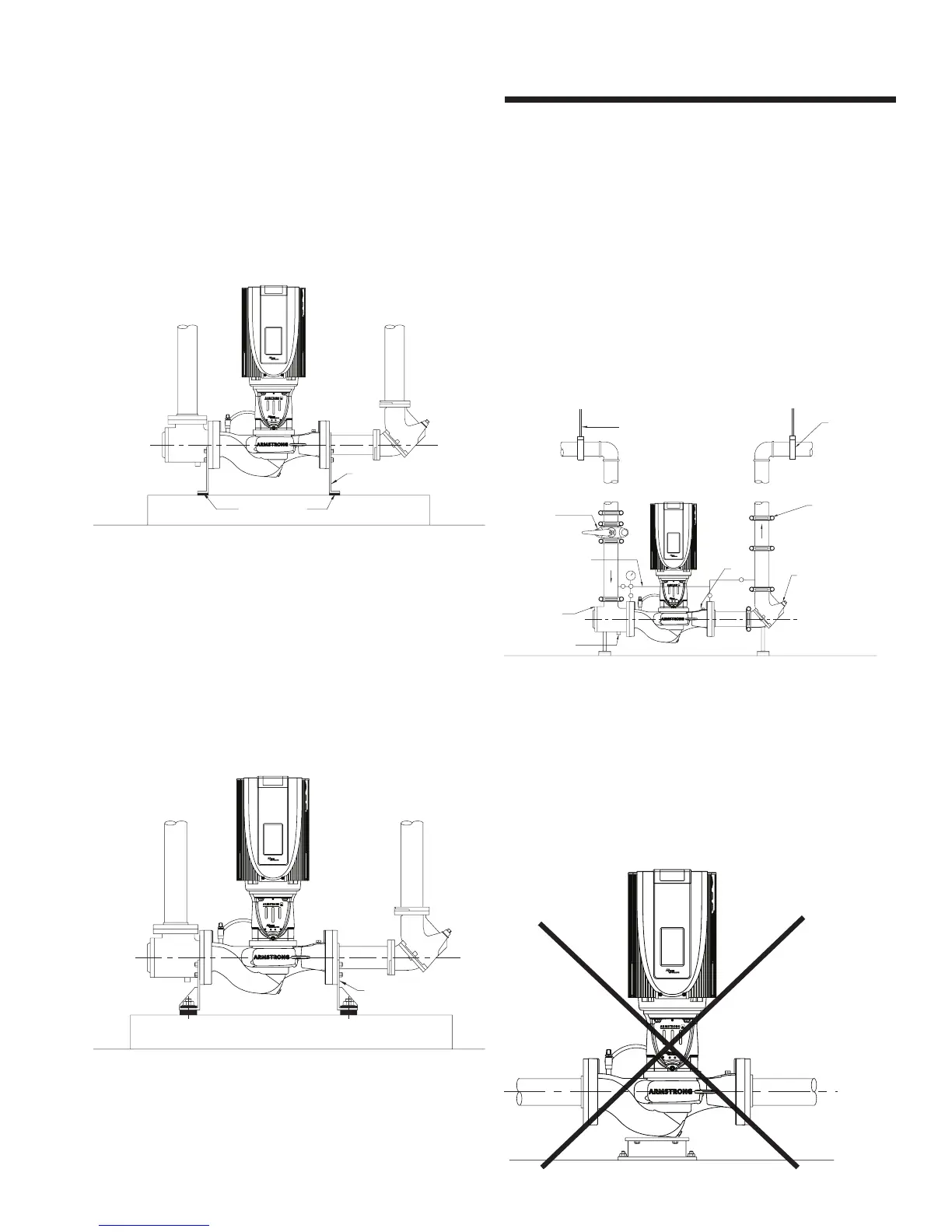

fig. 1.2.2.6

Isolation Pads

Stanchion Plates

1.2.2.7

fig. 1.2.2.7 illustrates installations with stanchion plates for

seismically active regions. Seismically rated isolation pads

or snubbers with bolts isolated from the stanchion plates are

installed to restrain the pump during a seismic event. Pipe

hangers carry the weight of the equipment as seismic com-

ponents are designed only to restrain the equipment during a

seismic event.

fig. 1.2.2.7

Seismically rated snubbers or pads and

conrete foundation

Stanchion plates

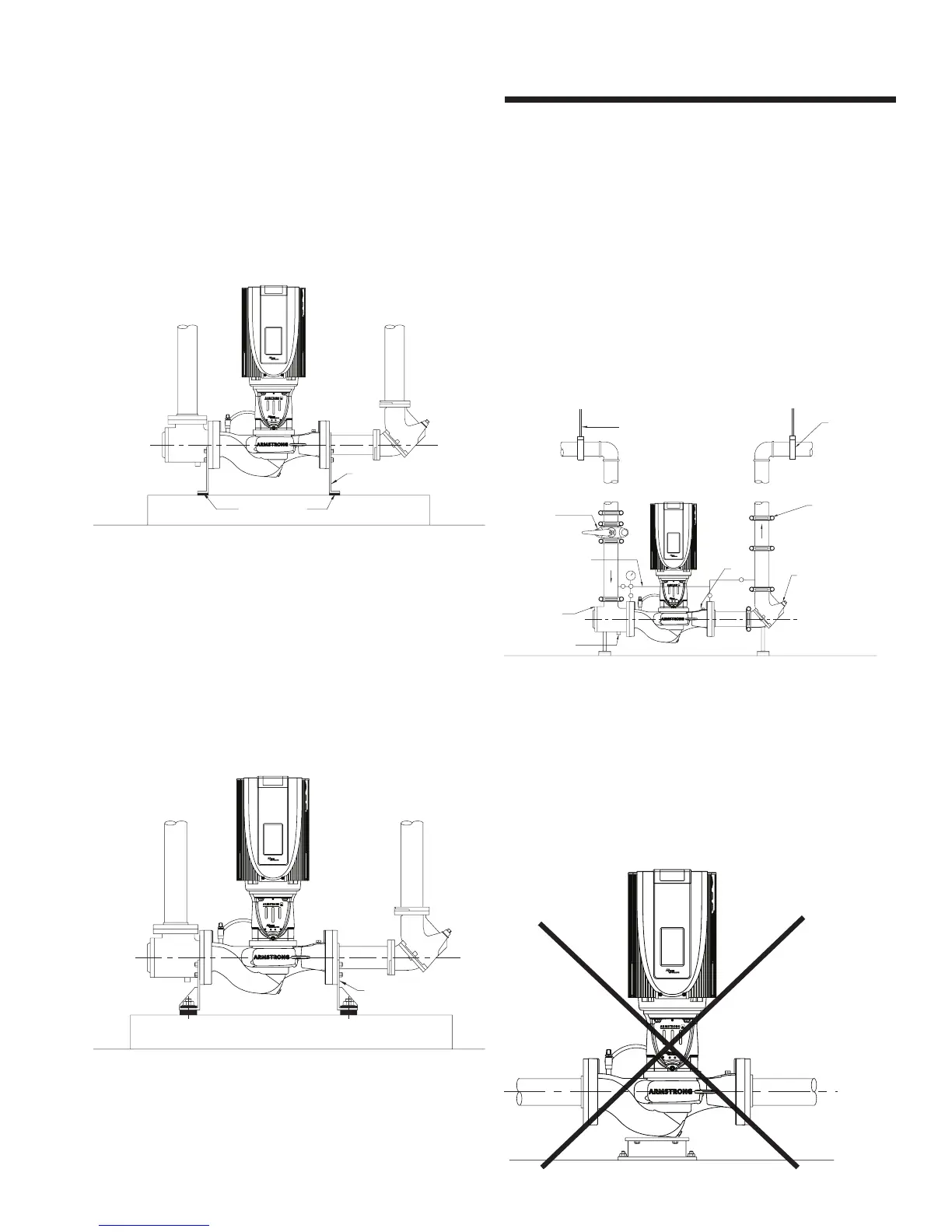

1.2.2.8

Many Vertical In-Line pumps are piped successfully into

grooved piping systems. In-line pumps are supported well by

grooved piping however flange adapter locking devices or a

welded flange at the pump should be used to prevent the pos-

sibility of pipe mounted pumps rotating in the piping. Armstrong

oers grooved suction guides with cast-in outlet flanges and

Flo-Trex valves with Armgrip™ fittings to prevent this possibility.

fig. 1.2.2.8

ain connection

System inlet

Recommended field

pressure gauge

piping arrangement

Flo-Trex valve

Pet cock

(typ.)

Pipe hanger

(typ.) See

size and type

System outlet

Flush

line

Gruvlok 7000 flex

coupling (typ.)

7700 butterfly

valve

Hangers support the weight of the

filled piping, pumps and fittings

1.2.2.9

Connecting the pump to a permanent rigid base (fig. 1.2.2.9)

is not recommended unless isolated from the piping by flexible

connectors and the base isolated from the building structure

on an inertia base. (fig. 1.2.2.9 is generally acceptable when

using plastic piping).

fig. 1.2.2.9

Loading...

Loading...